Combat In-Tank Corrosion

The Veeder-Root HydrX Fuel Conditioning System combats in-tank corrosion by providing continuous water removal within diesel storage tanks. The unique design of HydrX removes water from the lowest point in the tank, preventing water from stagnating on the tank bottom and breeding microbial contaminants. The integrated filtration removes entrained water, rust, sand, and microbial particulate from the fuel, polishing it before returning clean fuel back to the tank.

Keep your fuel within specification and maintain equipment at peak efficiency to avoid unplanned site shutdowns.

Improve Fuel Quality and Maintain Optimal Flow Rate at the Dispenser

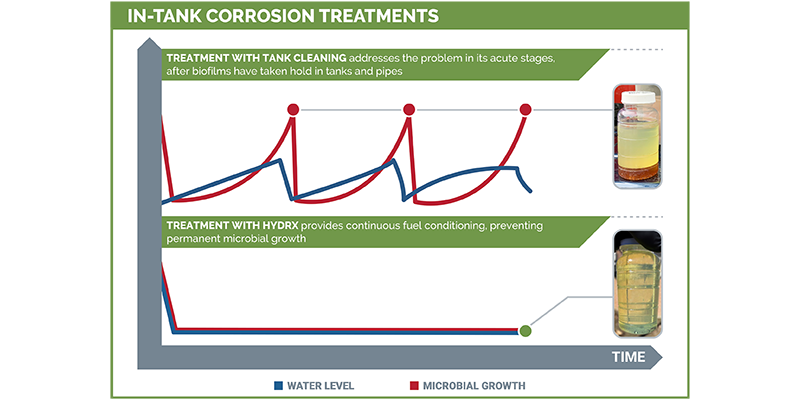

Micro-biologically Influenced Corrosion, caused by growing microbes in water, has been a persistent issue that causes fuel degradation and premature equipment breakdown. Water contamination is the chief enemy of diesel storage. Stagnant water on tank bottoms is the breeding ground for microbial activity, which leads to the production of corrosive acids and microbial waste. Continuous water removal is the only long-term, sustainable solution for optimal tank health and diesel fuel quality.

How it Works

- The Water Intake Device (WID) is inserted through a spare bung in the Submersible Turbine Pump (STP) sump, which rests on the tank bottom to access water from the lowest point in the tank.

- The WID is a multi-mode device powered by the STP to collect water from the bottom of the tank and entrained in the fuel, delivering it to the Fuel Conditioner in the sump. Fuel and water are separated through filtering, and the water kept in the containment vessel.

- Vacuum mode uses suction from the STP port to pull fuel, water, and particulate into the fuel conditioning system.

- Sweep mode uses clean fuel to push water and particulate to the lowest point in the tank, where it can be picked up by the WID.

- Polishing mode is activated when the vacuum and sweep modes are complete (i.e., no more water is being collected). This mode provides a fine polish for optimal fuel quality.

- Separation and filtration purifies the fuel before returning it to the tank.

- The TLS-450PLUS and TLS4 Automatic Tank Gauges (ATGs) allow the user to see the status of HydrX onsite or remotely, including the water level in real-time and alerts when the water containment vessel is full.

- When the water containment vessel is full, the system will automatically shutdown until the water is removed from the containment vessel.

- To remove the water, a site technician would quick-connect to the water containment vessel and drain water into a separate container for disposal.

Combating Corrosion with Cumberland Farms

Learn how the HydrX Fuel Conditioning System prevents corrosion from eating away at the bottom line for Cumberland Farms.

Read the Case StudyInstallation Requirements & Parts

Installation Requirements & Resources

The components of the HydrX Fuel Conditioning System are customized based on the unique configuration of each diesel storage tank.

Site Inspection Guide

In order to optimize the functionality of the Water Intake Device that accesses water from the lowest point in the tank, a completed Site Inspection Guide must be submitted to Veeder-Root Customer Service at customerservice@veeder.com prior to ordering

HydrX System Configurator

Complete the HydrX Fuel Conditioning System Site Inspection Guide (576047-355) to obtain the necessary information to input into the configurator and pinpoint the part numbers required for your HydrX Fuel Conditioning System.

Accessories & Replacement Parts

Accessories and replacement parts to configure and maintain the HydrX Fuel Conditioning System to meet specific site needs.

Documents

- HydrX Fuel Conditioning System Datasheet (576047-360)

- HydrX Fuel Conditioning System Specification Sheet (576047-359)

- HydrX Fuel Conditioning System Submittal Form (577014-471)

- HydrX Fuel Conditioning System Frequently Asked Questions (576047-346)

- HydrX Fuel Conditioning System Site Inspection Guide (576047-355)

- Combat Corrosion Flyer (576047-362)

- HydrX Fuel Conditioning System Site Preparation Guide (576047-431)

- Veeder-Root Commercial & Industrial Product Guide (576047-533)

- Veeder-Root Commercial Fueling Station Ecosystem (576047-612)

- HydrX Fuel Conditioning System Installation Manual (577014-446)

- HydrX Fuel Conditioning System Quick Help - ATG Control (577014-493)

- HydrX Fuel Conditioning System Setup & Operation Manual - ATG Control (577014-492)

- HydrX Fuel Conditioning System - FCC to ATG Conversion Guide (577014-490)

- HydrX Fuel Conditioner Inlet/Outlet Filter Replacement Instructions (577014-473)

- HydrX Fuel Conditioner Waste Water Tank Draining Instructions (577014-474)

- HydrX Fuel Conditioner Mag Probe Replacement Instructions (577014-469)

- HydrX Fuel Conditioner Siphon Cartridge Service/Installation Guide (577014-478)

- HydrX Fuel Conditioner Offset Mounting Bracket Installation Guide (577014-476)

- HydrX Fuel Conditioner Pressure Sensor Replacement Instructions (577014-470)

- HydrX Fuel Conditioning System Setup & Operation Manual - FCC Control (577014-466)

- HydrX Fuel Conditioning System Quick Help - FCC Control (577014-472)

- HydrX Fuel Conditioner Solenoid Valve Service Guide (577014-510)

Featured Articles

Is Water Hiding in your Fueling System?

There are many reasons to consider water as a serious threat that needs to be removed.

Read More

Why Does Water Need to be Removed Continuously?

Once you realize that you have water in your tank, or the potential for a corrosive environment, you will need to weigh your options for how to best handle the situation.

Read More

A Corrosive Impact on Fuel Quality

Corrosion within a fueling system can affect the quality of the fuel and impact the integrity of their equipment.

Read More

The Cost of Doing Nothing

Corrosion within a diesel underground storage tank is a long-term problem for a gas station.

Read More

Getting the Water Out of your Tank

Maintaining a water-free diesel storage tank is essential to combating corrosion in your fueling system.

Read More

Is your Corrosion Management Program Working?

Read more about the indicators that the condition in your diesel storage tank is improving.

Read More