CARB Certified Vapor Recovery

Veeder-Root’s California Air Resources Board (CARB) certified In-Station Diagnostics (ISD) system provides the most accurate vapor recovery detection available in the industry.

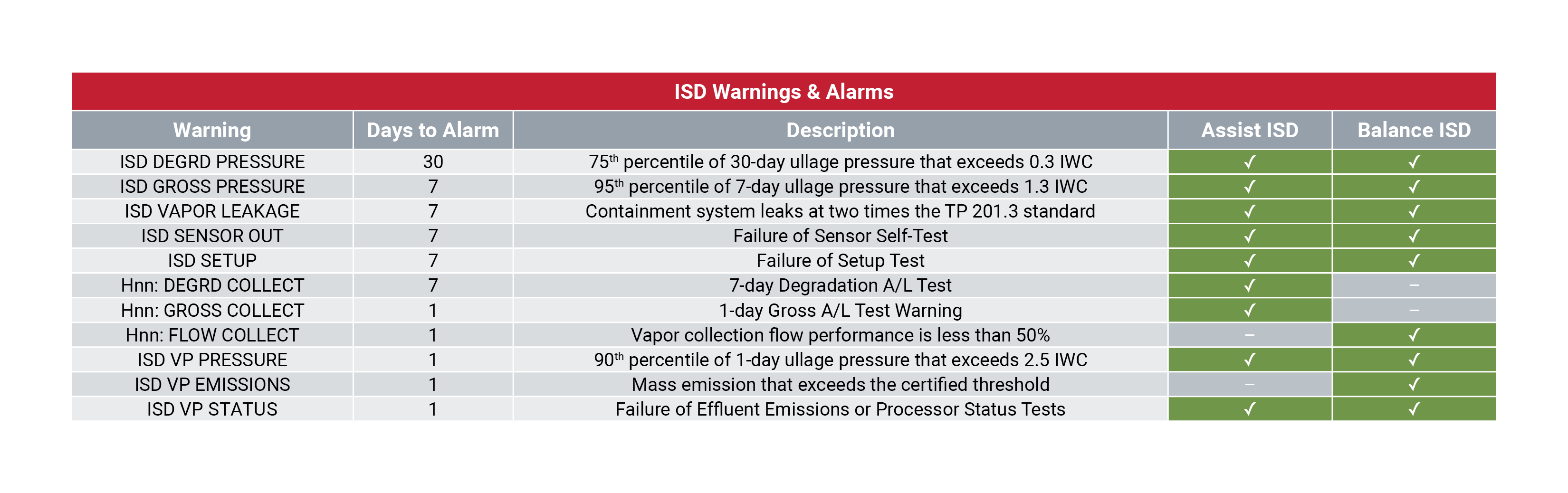

The Veeder-Root ISD system continuously monitors the vapor recovery equipment, maintains test records, provides test reports, and generates warnings or alarms following equipment failure. It can now be added to the TLS-450PLUS console, which provides remote access and enhanced security, in addition to the latest features not available on legacy TLS consoles.

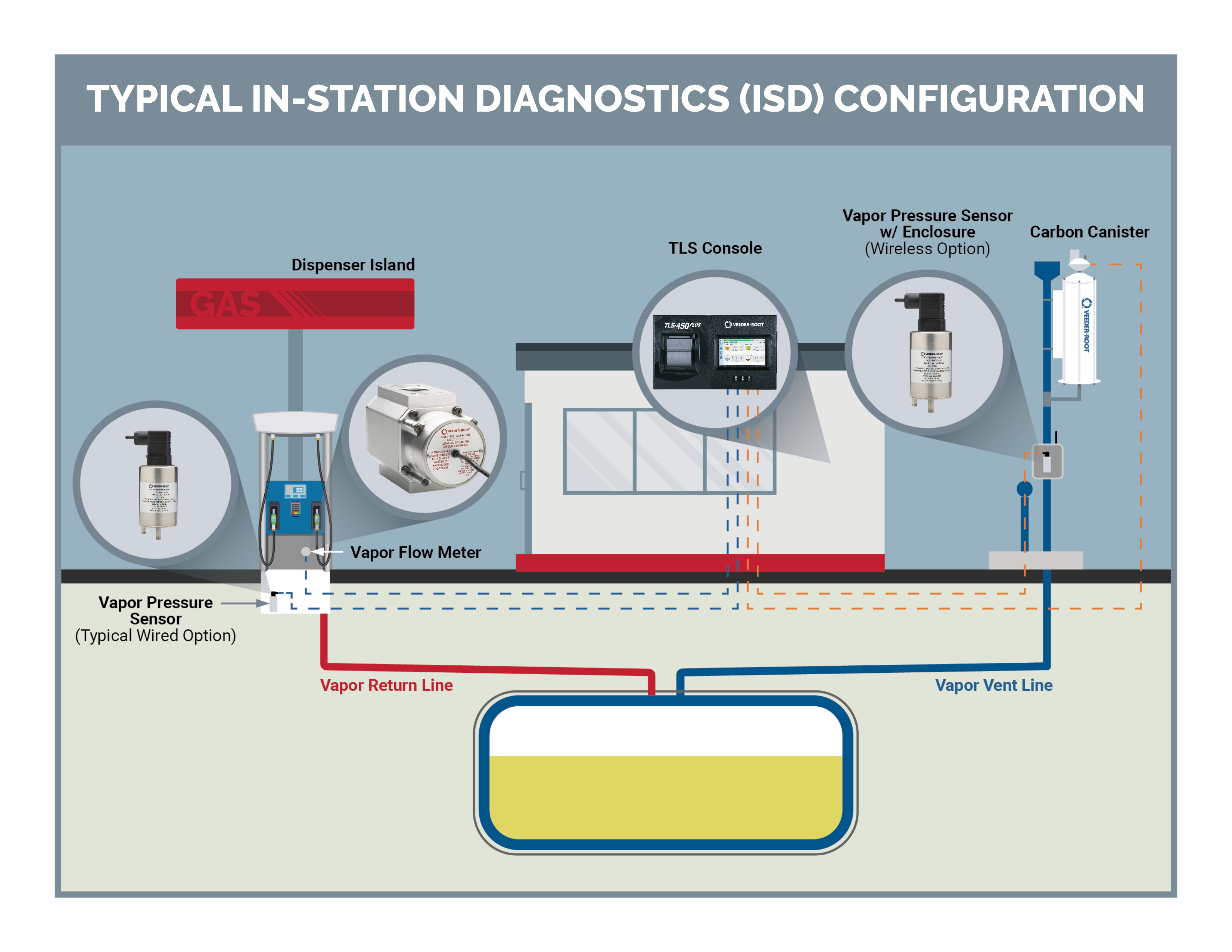

System Components

- Vapor Flow Meter – Provides ISD with the volume of vapor recovered during vehicle refueling for continuous vapor collection monitoring

- Assist Vapor Flow Meter – Designed to withstand the harsh vapor recovery environment found in systems with vapor vacuum pumps

- Balance Flow Meter – Designed for use in pressure sensitive balance systems to maintain accuracy and minimize false alarms

- Vapor Pressure Sensor – Provides ISD with tank ullage pressure for vapor containment leakage and overpressure monitoring

- ISD Software Enhancement Feature – Unlocks the ISD software in the TLS console to provide continuous vapor recovery monitoring

Documents

- In-Station Diagnostics (ISD) Datasheet (576047-065)

- TLS-450PLUS with In-Station Diagnostics (ISD) Frequently Asked Questions (576047-496)

- Carbon Pressure Management System Datasheet (576047-141)

- TLS-RF Wireless 2 System Datasheet (576047-122)

- Benefits of Upgrading to the TLS-450PLUS (576047-304)

- TLS-450PLUS Sell Sheet (576047-250)

- TLS-450PLUS, TLS4, & TLS4B Automatic Tank Gauges Specification Sheet (576047-204)

- Pressure Management Control (PMC) TLS-450PLUS Consoles for VR Polisher Install, Setup, & Operation Manual (577014-460)

- In-Station Diagnostics (ISD) TLS-450PLUS Consoles for Healy Assist Install, Setup, & Operation Manual (577014-461)

- In-Station Diagnostics (ISD) Quick Reference Guide for TLS-450PLUS Consoles (577014-462)

- In-Station Diagnostics (ISD) Pressure Management Control (PMC) TLS-450PLUS Consoles Troubleshooting Guide (577014-463)

- In-Station Diagnostics (ISD) TLS-450PLUS Consoles for VR Polisher and Healy CAS Install, Setup, & Operation Manual (577014-484)