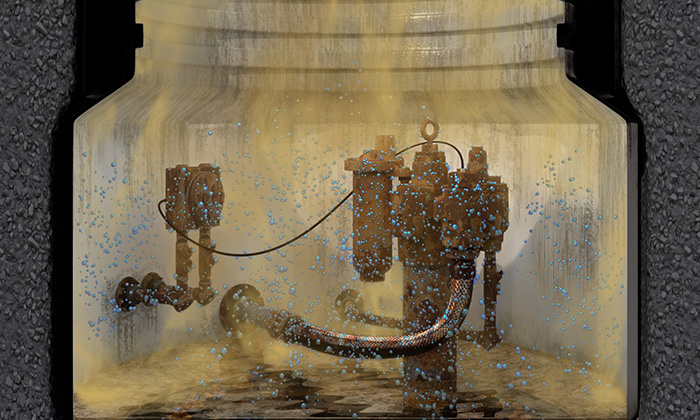

YOUR FUELING EQUIPMENT IS UNDER ATTACK

Corrosion of fueling equipment in tanks and sumps causes fuel degradation and premature equipment breakdown. Protect your fueling equipment from the effects of corrosion with Veeder-Root’s portfolio of products engineered to survive the harshest conditions. We offer the right equipment for the specific conditions at your fuel site.

What are the first steps to limiting corrosion?

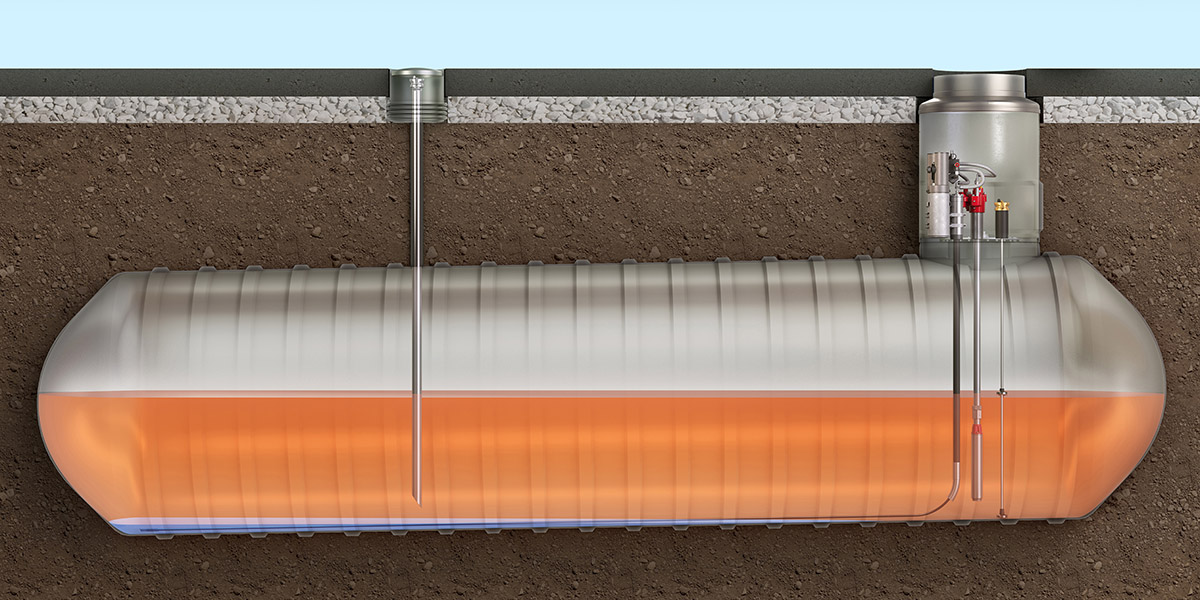

In order to limit corrosion of your fueling equipment, you need to eliminate the presence of water. Water provides an environment where microbial growth causes acetic acid, which creates a corrosive condition that can lead to filter plugging, pump and injector problems, and buildup of biofilms inside the tank.

There is a strong correlation between water control and fuel acidity. Higher acidity levels correlate with higher water levels in the tank and the prevalence of corrosion. Detecting and controlling water ingress from delivery, flooded spill buckets, condensation, and leaky seals are the first steps to limiting corrosion, and avoided unplanned downtime and increased maintenance costs.

- Ensure riser pipes and fittings are installed appropriately

- Ensure fittings, cord grips, manway caps, gaskets and electrical conduit are watertight

- Repair leaky seals

- Empty spill buckets regularly

Water ingress through deliveries and condensation are not as easy to detect and control.

There are some key indicators that corrosion may be taking place at your fuel site. Conditions to look out for include:

- Vinegar smell in the fuel

- Line leak failures, not holding pressure

- Standing water in the tank, as indicated by probe water alarms

- More frequent dispenser filter changes

- Hazy fuel within diesel storage tank, typically more prevalent on tank bottoms

- Evidence of scale and rust on internal components

- Inside of riser pipes

- Under-side of bungs

- STPs and UMPs

- Valves

Advanced Corrosion Protection

Key Questions to Consider when Combating Corrosion

It's important to understand the conditions in your tank and sump in order to best determine the right equipment to protect your fuel site.

| If Yes, Consider Installing: | |

|---|---|

| Do you have standing water in the tank? | HydrX™ |

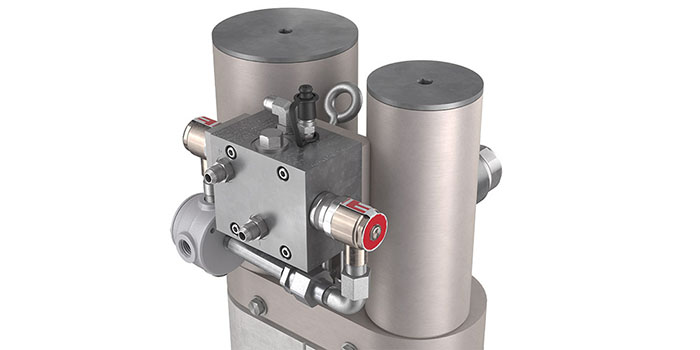

| Do you anticipate standing water in the sump? | Red Armor STP + Stainless Steel Riser |

| Are you experiencing high humidity in the sump or have installations in a high humidity environment? | Red Armor STP + Stainless Steel Riser |

| Are you changing diesel dispenser filters more frequently (e.g., humbugs resulting in dark particulate in the filters)? | HydrX |

| Do you see evidence of scale and rust on internal diesel fuel system components? | HydrX |

| Are you operating in 100% Diesel, B100, or other Biodiesel Blends? | HydrX |

| Are you operating in Clear Gas [no Ethanol] or 100% Diesel? | The Red Jacket STP |

| Are you operating in E85 or B-20 - B-100? | Red Jacket Alcohol Gas STP |

| Are you operating in E10 - E15? | The Red Jacket STP |

| Are you concerned about corrosion from Ultra-Low Sulfur Diesel (ULSD)? | HydrX + Red Armor STP |

| Are you concerned about in-sump corrosion from the High-Ethanol Blends? | Red Armor STP |

Protect Diesel Fuel Equipment from Corrosion

In-tank corrosion has been a significant challenge in the retail fueling industry for over a decade. Microbial growth feeds on contamination and components of diesel fuel and creates a biofilm that adheres to fueling system equipment and tank walls. High acid values within the biofilm create a corrosive condition that leads to the degradation of equipment.

Learn more about Solutions for In-Tank CorrosionProtect Your Business from the Effects of In-Sump Corrosion

Corrosion of equipment in sumps causes deterioration and shortens its useful life span. As corrosion advances it has the potential to affect the integrity of piping and electrical systems, and the serviceability of submersible turbine pump equipment.

Learn more about solutions for in-sump corrosion