Cleaner & Clearer Fuel Samples

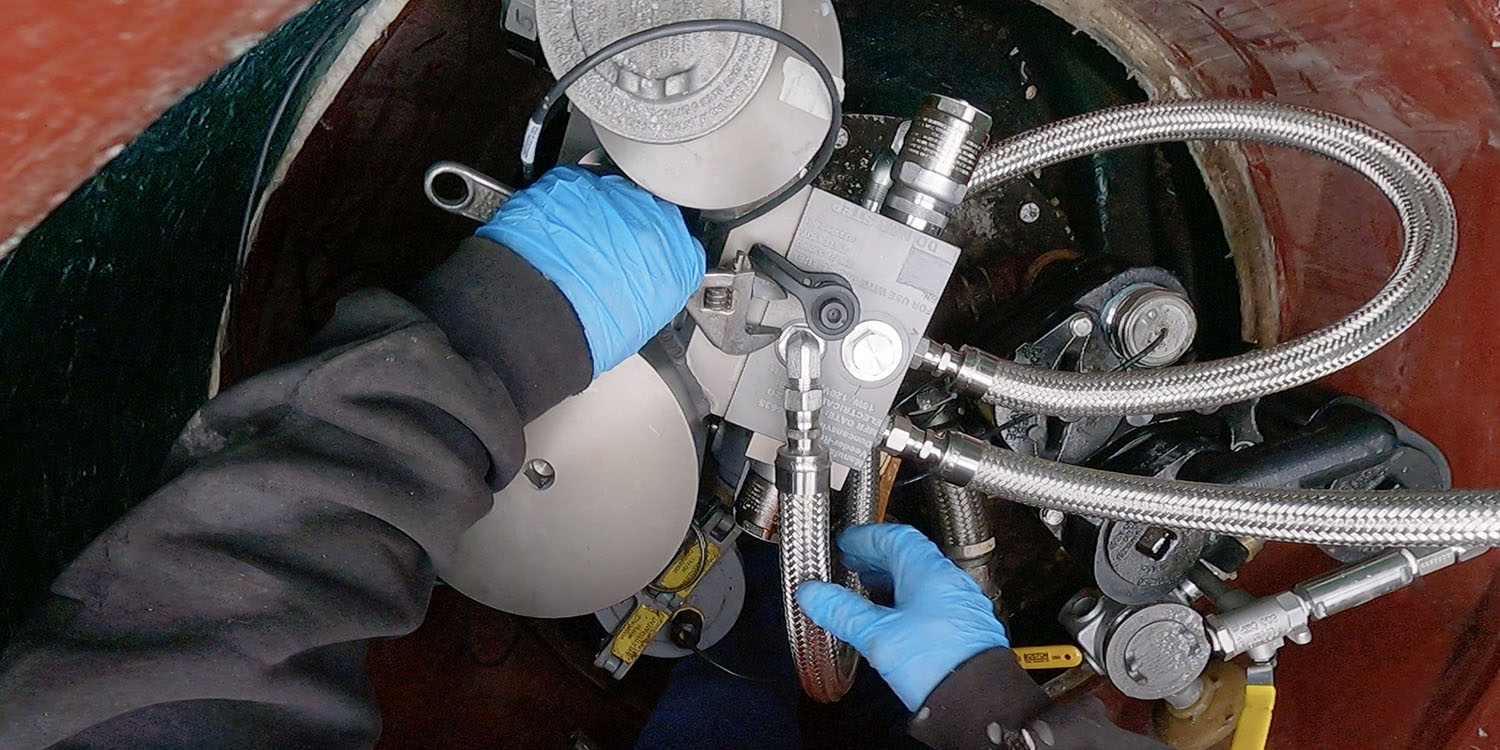

As the water is removed from the tank, HydrX is also filtering the fuel to remove entrained water, rust, sand, and microbial particulate. It then returns clean fuel to the tank. The result of this process is the fuel in your tank is cleaner and clearer, which means the fuel at the bottom of the tank is as clear as what you are dispensing at the nozzle. This visual check tells you that the corrosion management program is working to protect diesel fuel from degradation and contamination.

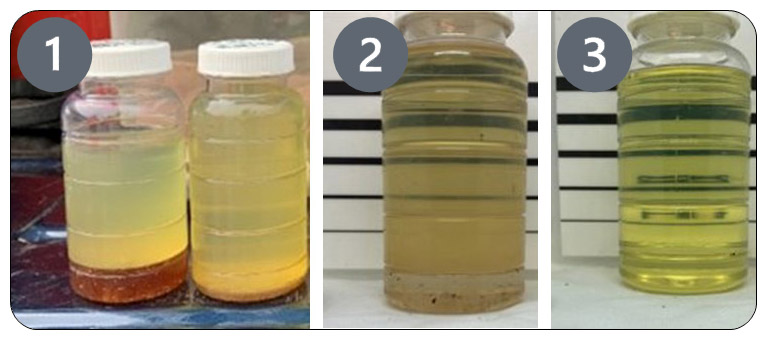

A corrosion management program that includes HydrX not only removes water but also filters and polishes fuel. Here we see the progression of fuel samples taken from the bottom of the same underground storage tank at the beginning of a corrosion management regiment:

- Initial sample taken at site survey. The sample is very hazy, there is standing water present and a heavy layer of particulate from the tank bottom.

- Sample taken two months after a tank cleaning and with no conditioning or fuel polishing for 30 days. The fuel sample has less particulate but is still hazy and there is standing water present within the sample. If nothing is done conditions within the tank will continue to slowly revert back to the starting point.

- This sample was taken after the HydrX system had been running for 33 days. Fuel sample is clear with no visible particulate and no standing water.

Maintaining Desirable Fuel Acidity

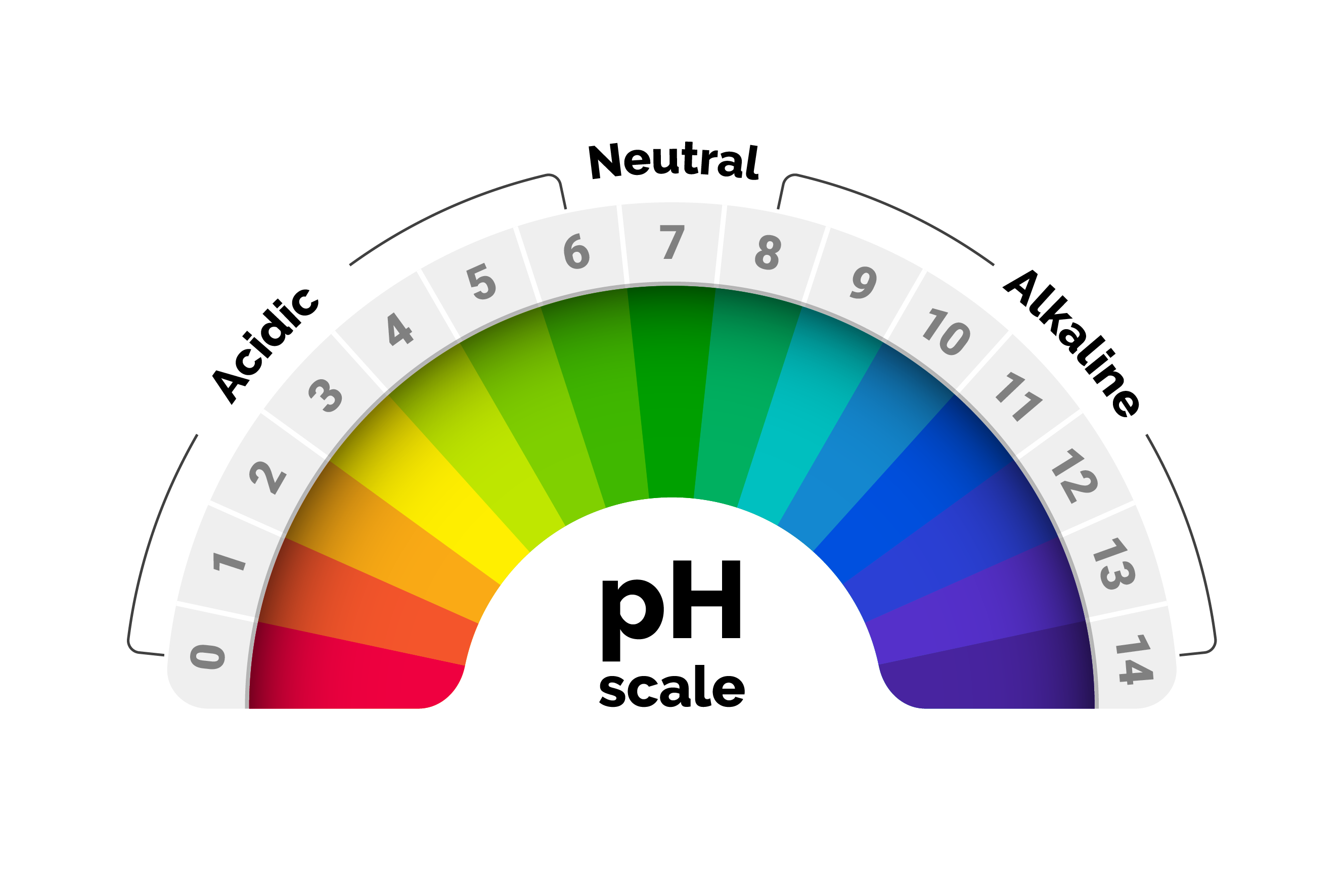

The acidity of the fuel within the tank is indicative of how corrosive the underground storage tank environment is. One way to determine its acidity is to measure the pH of the fuel. The lower the pH number, the more acidic the fuel is. For tanks that have a corrosive environment, the fuel may have a pH between 4.5 – 6.

After the HydrX system has been in operation for a week or two, we have seen the pH of the fuel within the UST trend towards a pH range of 6.5 – 7. A pH measurement of 6.5 is at the very edge of a passive oxide surface with no ongoing corrosion at all.

You Be The Judge

Adding a HydrX Fuel Conditioning System to your site increases the useful life of your diesel fueling equipment and improves fuel quality. Fill out the brief form below to find out more about HydrX.

Read all our Combat Corrosion Articles

Water is integral to corrosive environments and a serious threat to diesel storage tanks and fuel equipment health. Learn more about the cause and impact of corrosion, and steps you can take to mitigate it.

Read More