Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

Over the past four years, Cumberland Farms and Veeder-Root have been conducting a thorough analysis of the HydrX™ Fuel Conditioning System at its first installation site. The results the team found were striking:

- No emergency diesel maintenance was needed since HydrX was installed.

- Fuel quality was clean and bright, with no standing water or particulate.

- Longevity test performed on original HydrX filters, after 3 years, had over 86% life remaining. To ensure optimal system performance, the HydrX filters were replaced after 4 years.

The results clearly show HydrX is protecting the conditions inside the tank from water and microbial growth, with no leading indicators that they will be returning any time soon.

Note: It is recommended that the HydrX filters are changed every 12 months for optimal performance.

Tank bottom samples obtained from the same site, 1 year, 3 years, and 4 years after the HydrX installation. Baseline sample without HydrX (left) has standing water and significant microbial growth. The tank bottom samples post-HydrX installation are clean and bright with no standing water or particulate.

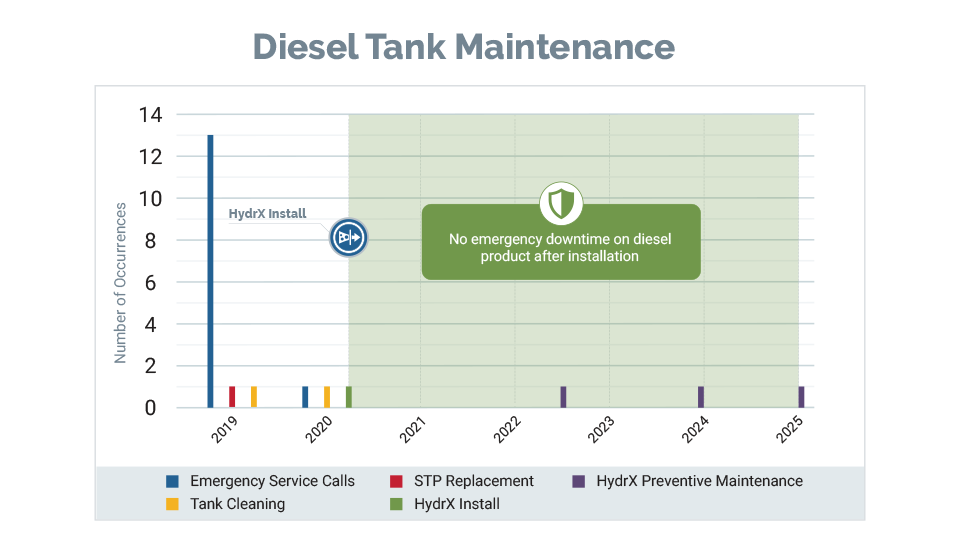

Diesel Tank Maintenance

The Diesel Tank Maintenance chart shows no emergency diesel tank maintenance was performed after the HydrX installation.

Talk to an Expert

Other systems work to remove water from only the immediate area around the Submersible Turbine Pump (STP) — HydrX is different.

HydrX uses suction tubes that extend along the Water Intake Device (WID), removing water all along the tank bottom. Its unique vacuum mechanism is powered by the STP, continuously circulating tank bottom fluids through a filter and water containment vessel in the sump. In addition to Cumberland Farms, HydrX is also installed with a number of national retailers, fleet fuelers, national distribution centers, and backup generators for critical infrastructure.

Download the latest version of this case study: "Combating Corrosion with Cumberland Farms"