Accurately Blend Biofuels On-site to Maximize Profitability

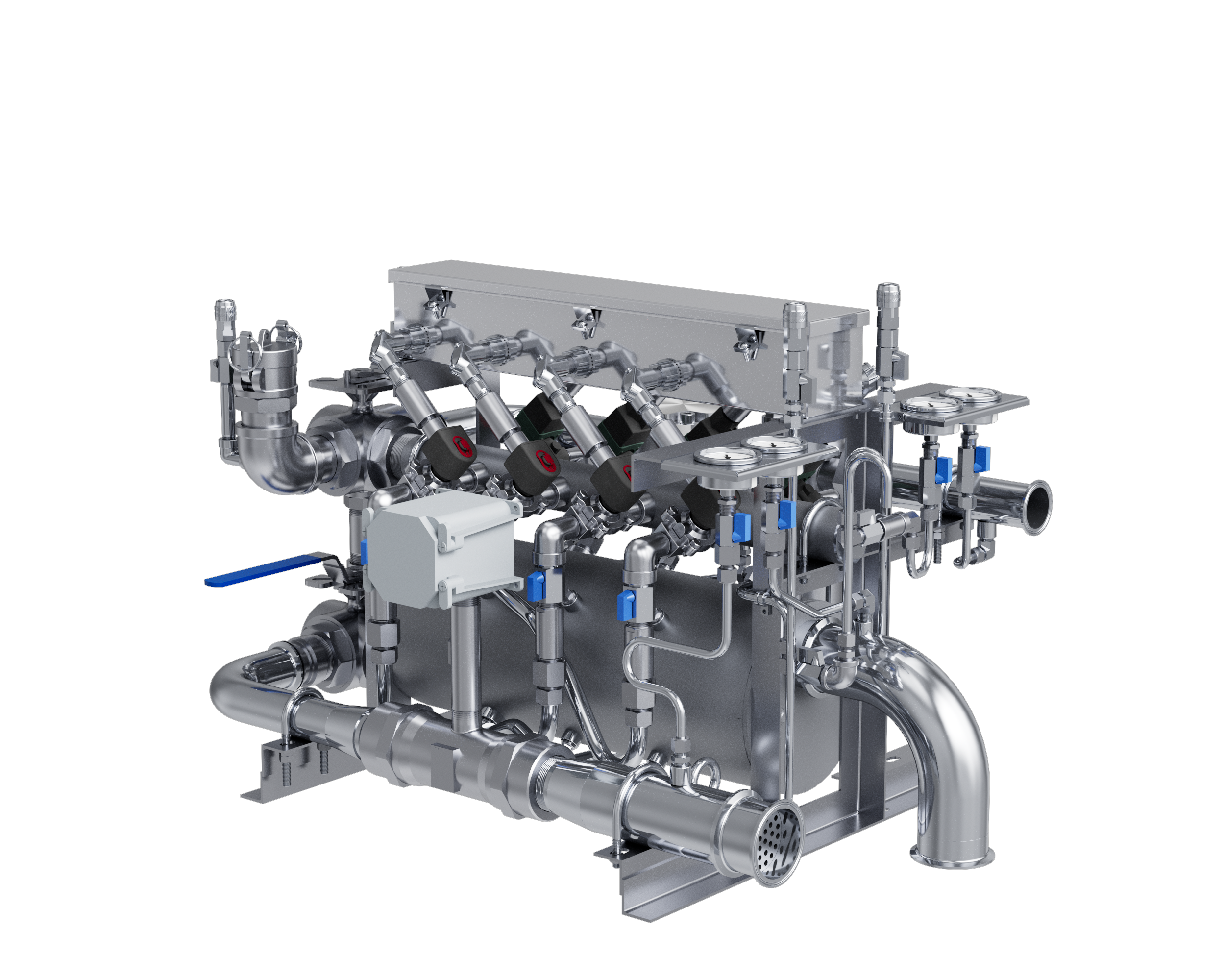

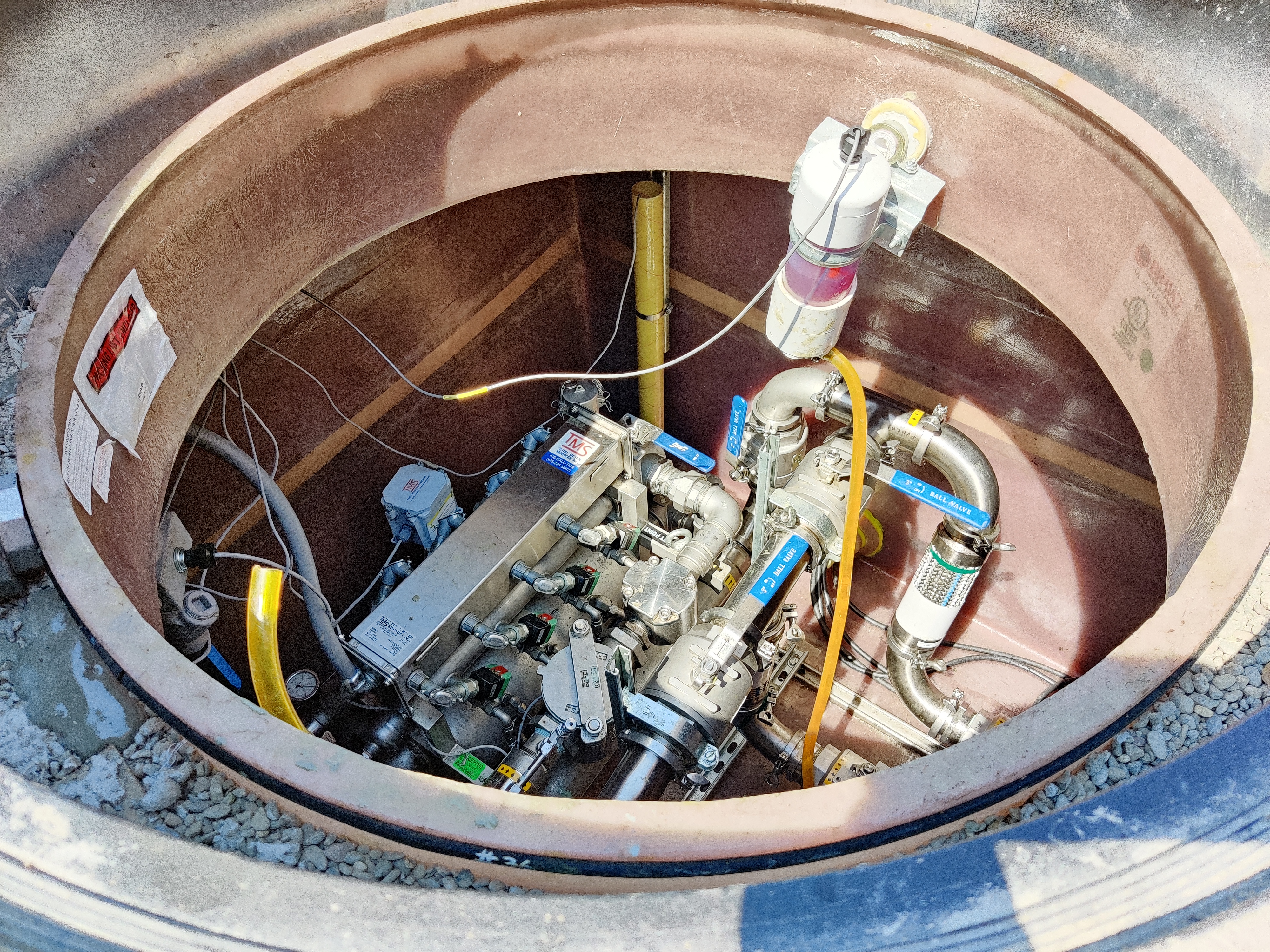

Using the same technology as the Additive Injection System, the Biofuel Blending System (BBS) is a versatile in-line solution that delivers biofuel blending within retail locations. It operates at a high degree of blend accuracy in a compact footprint, that can be installed aboveground or underground. The BBS integrates with Veeder-Root TLS Automatic Tank Gauges (ATGs) and Red Jacket® Submersible Turbine Pumps (STPs), and is backed by the largest distribution network in the industry.

Implement Biofuel Blending Capabilities On-site

- Automated in-line blending allows you to manage blend ratios on the fly without committing to batch blending an entire tank

- Integrated static blender improves blend uniformity to ensure compliance with Weights and Measures

- Compact footprint saves space on the forecourt

- Precision measurement allows for full traceability to blend ratio and automatic adjustments to maintain blend ratios

- Corrosion resistant construction provides reliable installation aboveground or underground

Benefits of a Biofuel Blending System for Retail Operations

- Gain greater flexibility on fuel pricing

- Capitalize on the Biodiesel Blender Excise Tax Credit

- Blenders registered with the IRS are eligible for a tax incentive of $1.00 per blended gallon of B100

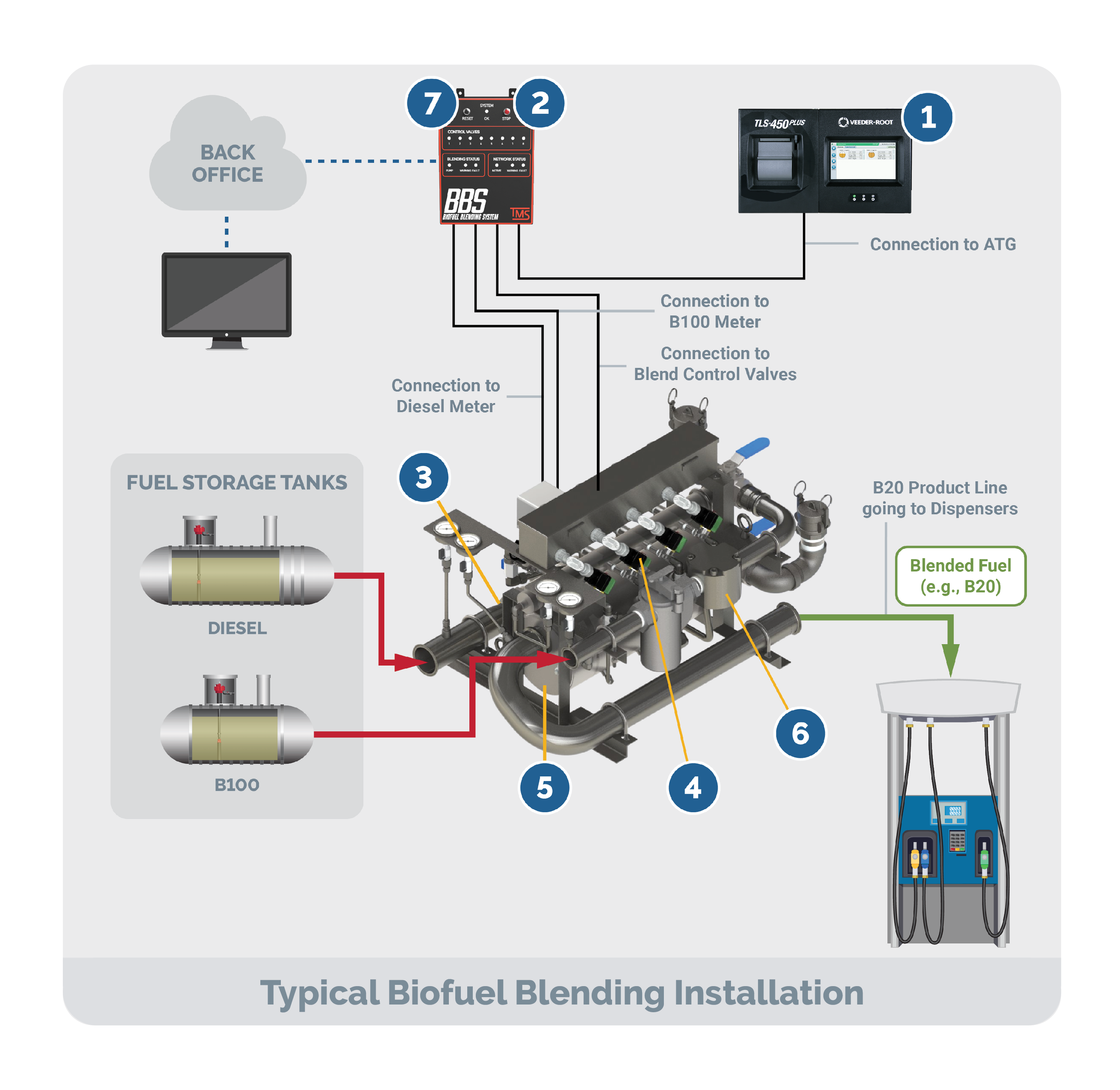

How It Works

- The TLS-450PLUS ATG receives the hook signal from the dispenser and turns on the diesel Red Jacket STP to start the flow of product

- The BBS Controller receives a signal that a dispensing event is taking place and creates a hook signal for the Red Jacket Alcohol Gas (AG) B100 STP

- The Diesel Meter on the BBS continuously monitors the flow of diesel through the blender

- The Blend Control Valves open to inject the correct amount of B100 into the blender

- The Static Blender mixes products within, resulting in a uniform blend that is sent to the dispenser island

- The B100 Meter is continuously monitored to ensure the target blend ratio is achieved

- The Blending Transactional Data is updated live in the BBS Controller, where it can be accessed via Application Programming Interface (API) or network connection

The Biofuel Blending System is in partnership with Total Meter Services Inc.

The Biofuel Blending System is in partnership with Total Meter Services Inc.