Once you realize that you have water in your diesel tank, you will need to weigh your options for how to best treat the potentially corrosive environment.

When water gets into a fuel storage tank containing Ultra-Low Sulfur Diesel (ULSD), it contributes to the onset of Micro-biologically Influenced Corrosion. Luckily there are a number of different solutions available to help with the problem of corrosion in diesel storage tanks.

Single Point In Time Solutions

First, you could use biocides to slow the microbial growth. The US Environmental Protection Agency (EPA) defines a biocide as "any poison that kills a living organism". As such, it is important to note that biocides can be hazardous to people and the environment and should only be applied by trained professionals and in controlled environments.

First, you could use biocides to slow the microbial growth. The US Environmental Protection Agency (EPA) defines a biocide as "any poison that kills a living organism". As such, it is important to note that biocides can be hazardous to people and the environment and should only be applied by trained professionals and in controlled environments.

It is recommended that biocides are applied when fuel inventory levels are high, and at a time when treated fuel can flow through the fueling system. This process allows any microbial waste to fall to the bottom of the ULSD tank. After the initial treatment there should be a diesel fuel polishing and storage tank cleaning to remove the microbial sludge and filter out any water.*

While this treatment kills off most, but not all, bacteria that are causing the biofilm, and ultra-low sulfur diesel tanks will require consistent treatments with this approach. This increases the chances that the biocides could negatively impact employees or the environment that come into contact with them, or that the microbes could develop resistance to the treatments.

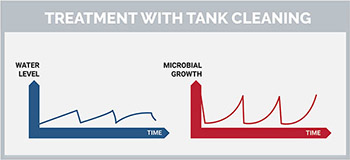

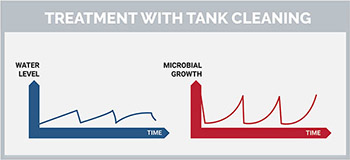

Another option is to do only an emergency tank cleaning and polishing in the ULSD storage tank. This will rid the tank of any water and clean the microorganisms out of the fuel, but there is no assurance how long the cleaning will last before you would need to do it again. Additionally, tank cleanings require that the tank is taken out of service and all fuel is removed, causing downtime at a gas station or fuel site.

Both biocides and a tank cleaning with fuel polishing are one-time events, so they do remove microorganisms in the short term but are going to be temporary corrosion control solutions. These methods alone are not a good long-term solution because the tank environment can revert to being conducive for corrosion as soon as water is introduced again.

Continuous Tank Cleaning

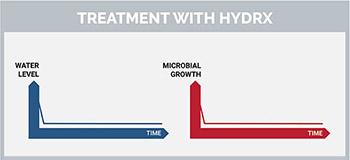

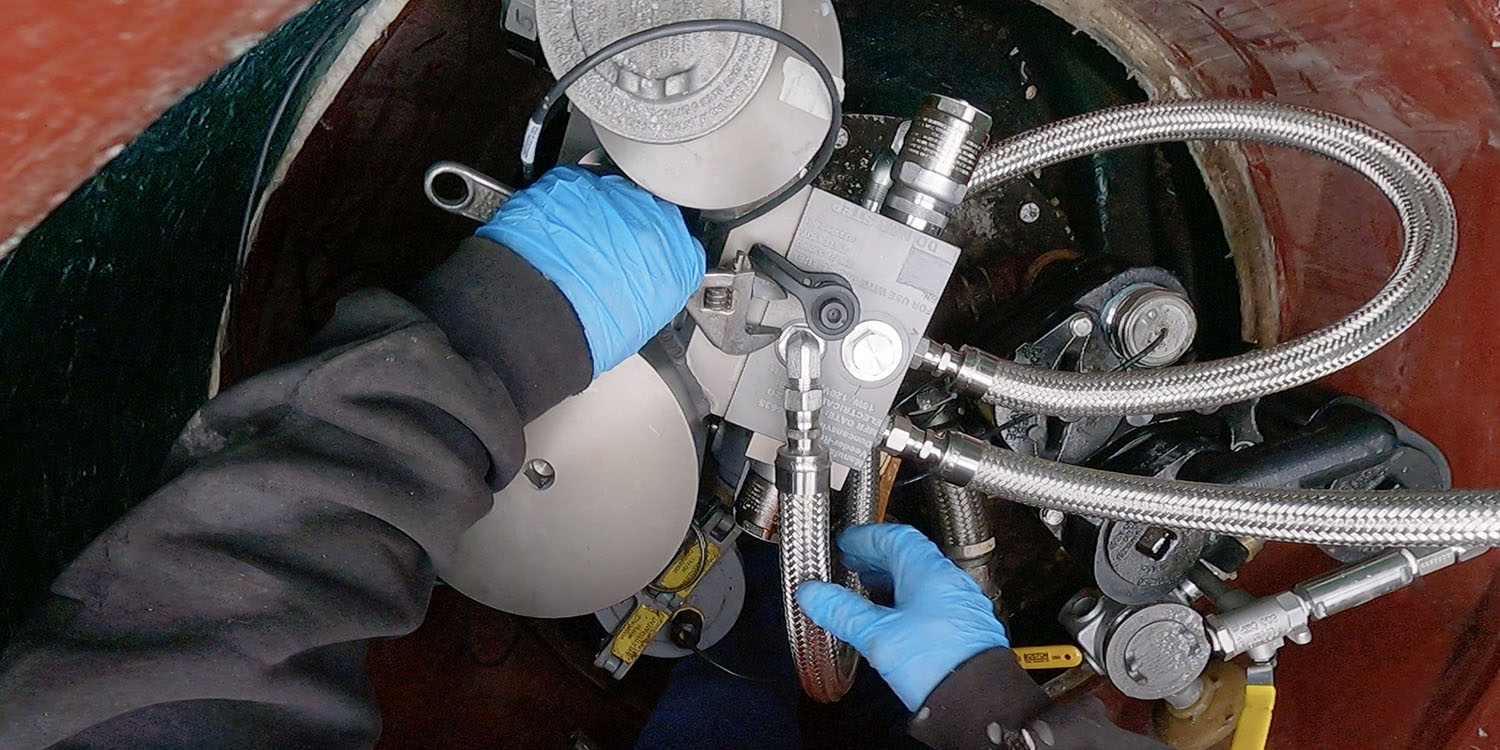

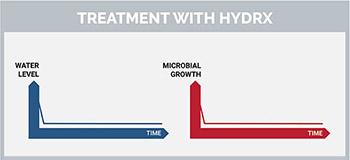

Fuel conditioning systems like HydrX™ are a great option for treating corrosive environments in underground storage tanks (UST) containing ultra-low sulfur diesel. This diesel fuel treatment system continuously filters out water, rust, sand, and microbial particulate. HydrX then acts as a fuel polisher, returning the cleaned ULSD back to the tank. The benefit of the system is that it allows for water and bacteria removal on an ongoing basis, which prevents the conditions necessary for UST corrosion.

Unlike other fuel conditioners, the HydrX Fuel Conditioning System includes a Water Intake Device that reaches the lowest point of the tank bottom to ensure that all stagnant water is removed. Entrained water in the fuel is then removed by the integrated filtration element, maximizing water removal and providing optimal fuel quality.

Unlike other fuel conditioners, the HydrX Fuel Conditioning System includes a Water Intake Device that reaches the lowest point of the tank bottom to ensure that all stagnant water is removed. Entrained water in the fuel is then removed by the integrated filtration element, maximizing water removal and providing optimal fuel quality.

* GUIDANCE FOR UNDERGROUND STORAGE TANK MANAGEMENT AT ULSD DISPENSING FACILITIES, Clean-Diesel.org. Accessed June 9th, 2021, https://clean-diesel.org/pdf/guidanceforundergroundstoragetankmanagement_final.pdf

First, you could use biocides to slow the microbial growth. The US Environmental Protection Agency (EPA) defines a biocide as "any poison that kills a living organism". As such, it is important to note that biocides can be hazardous to people and the environment and should only be applied by trained professionals and in controlled environments.

First, you could use biocides to slow the microbial growth. The US Environmental Protection Agency (EPA) defines a biocide as "any poison that kills a living organism". As such, it is important to note that biocides can be hazardous to people and the environment and should only be applied by trained professionals and in controlled environments. Unlike other fuel conditioners, the

Unlike other fuel conditioners, the