Why Red Jacket®?

Red Jacket’s unsurpassed expertise helps sites optimize fuel flow. Part of the industry’s leading Veeder-Root suite of products, Red Jacket’s family of Submersible Turbine Pumps (STPs) and Pump Controllers ensures that sites can pump fuel quickly, efficiently and safely – whether it’s motor fuel, diesel, aviation gasoline, LPG, ethanol/methanol or kerosene – in aboveground or underground storage tanks. As a Veeder-Root flagship product line, Red Jacket is backed by the largest network of distributors and authorized service contractors worldwide.

Why choose Fixed Speed over Variable Speed?

Red Jacket fixed speed technology is less expensive than variable speed to buy, own and operate. It delivers faster, more reliable fuel flow for the lowest cost of ownership. While you may have heard that variable speed will help you meet flow rate required with faster fill times during peak hours and provide power savings during non-peak hours, fixed speed equipment uses less power during operation and when idle.

Concerned with minimizing hydraulic hammer, a sudden spike in pressure resulting from a stop in flow within a pressurized piping system? Modern dispensers come with flow control features which makes it unnecessary to limit or 'dial-back' the STP. And, while pumping pressure with variable speed may be less, maximum pressure with fixed speed never can be higher than the design pressure, as modern dispensers limit flow within set parameters.

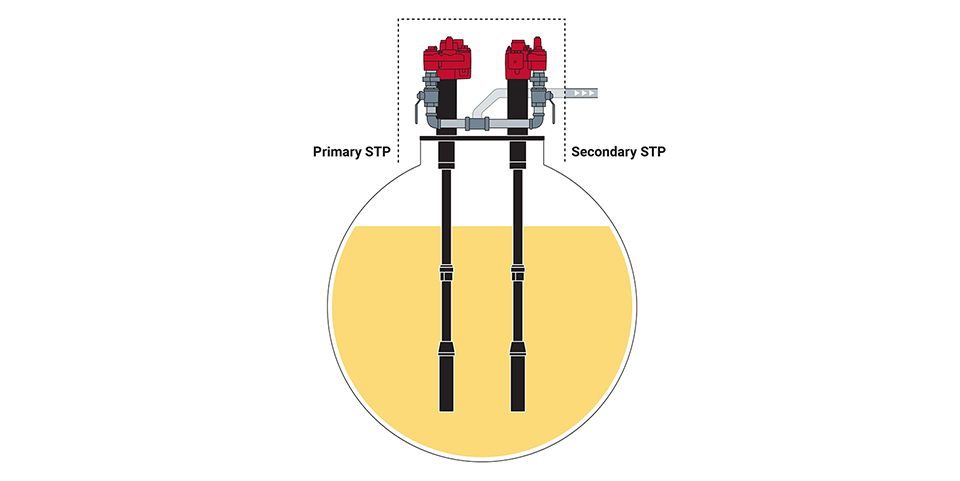

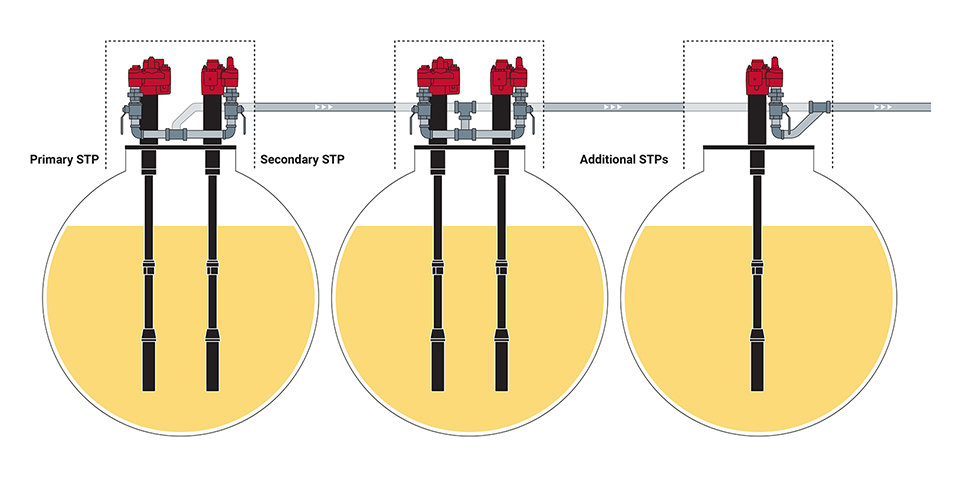

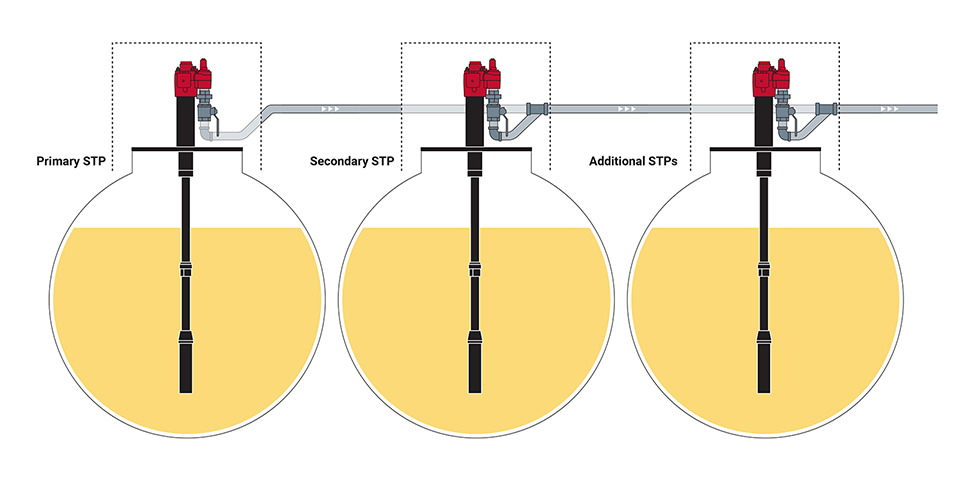

Line Manifolding & The Red Jacket 2+2 Solution

Two fixed-speed 2HP The Red Jacket Pumps manifolded together provide profit-saving protection against outage and better flow than a single 4HP pump (sump must be 42" in diameter or greater). When using a single 4HP pump, a pump or controller failure brings down a fueling site. The 2+2 Solution provides seamless redundancy and optimal flow for your site.

The 2+2 solution provides redundancy and backup operation with automatic failover. Switch-on-the-fly will switch submersible turbine pumps in live mode, without waiting for an on-hook condition, essential for maintaining balance at busy sites. Integrates control with Mechanical Leak Detection (MLD) or Pressurized Line Leak Detection (PLLD).

Determining which Red Jacket Submersible Turbine Pumps are right for your site

Red Jacket offers submersible turbine pumps in three levels of protection, along with a number of supporting products, to limit the effects of corrosion. Your level of protection depends on fuel types and your sump environment.

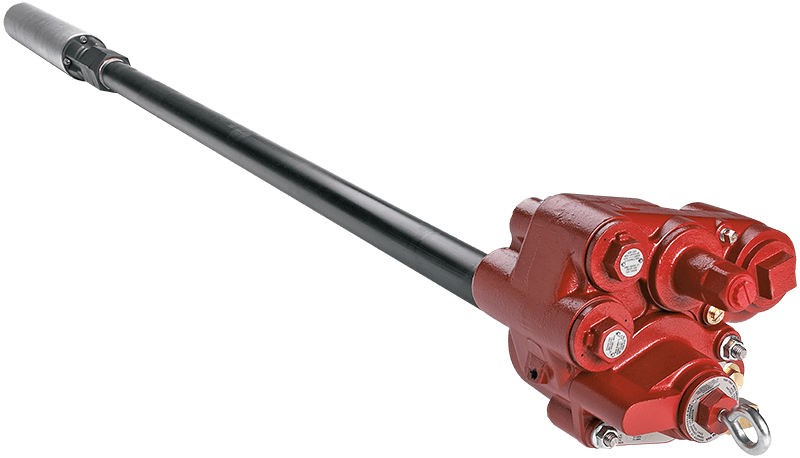

The Red Jacket STP

The Red Jacket Submersible Turbine Pump solution optimizes fuel flow and dispensing. It is the foundation model that sets the standard for high throughput, high reliability fueling applications.

Compatible with:

- 100% Diesel or Gasoline

- Ethanol and Methanol concentrations up to 15%

- MTBE, ETBE, or TAME concentrations up to 20%

The Red Jacket Alcohol Gas (AG) STP

The Red Jacket AG Submersible Turbine Pump has as additional 30% increase in stainless steel hardware from The Red Jacket STP. It has all the advantages of the Red Jacket Submersible Turbine Pump design, but was constructed with stainless steel on all parts exposed to the fuel path.

In addition to fuel types supported by The Red Jacket STP, The Red Jacket AG STP is UL79A and UL79B certified for use with renewable biofuels and is compatible with:

- Ethanol concentrations up to 90%

- Methanol and Biodiesel concentrations up to 100%

- Jet Fuel and AVGAS

- Kerosene and Fuel Oil

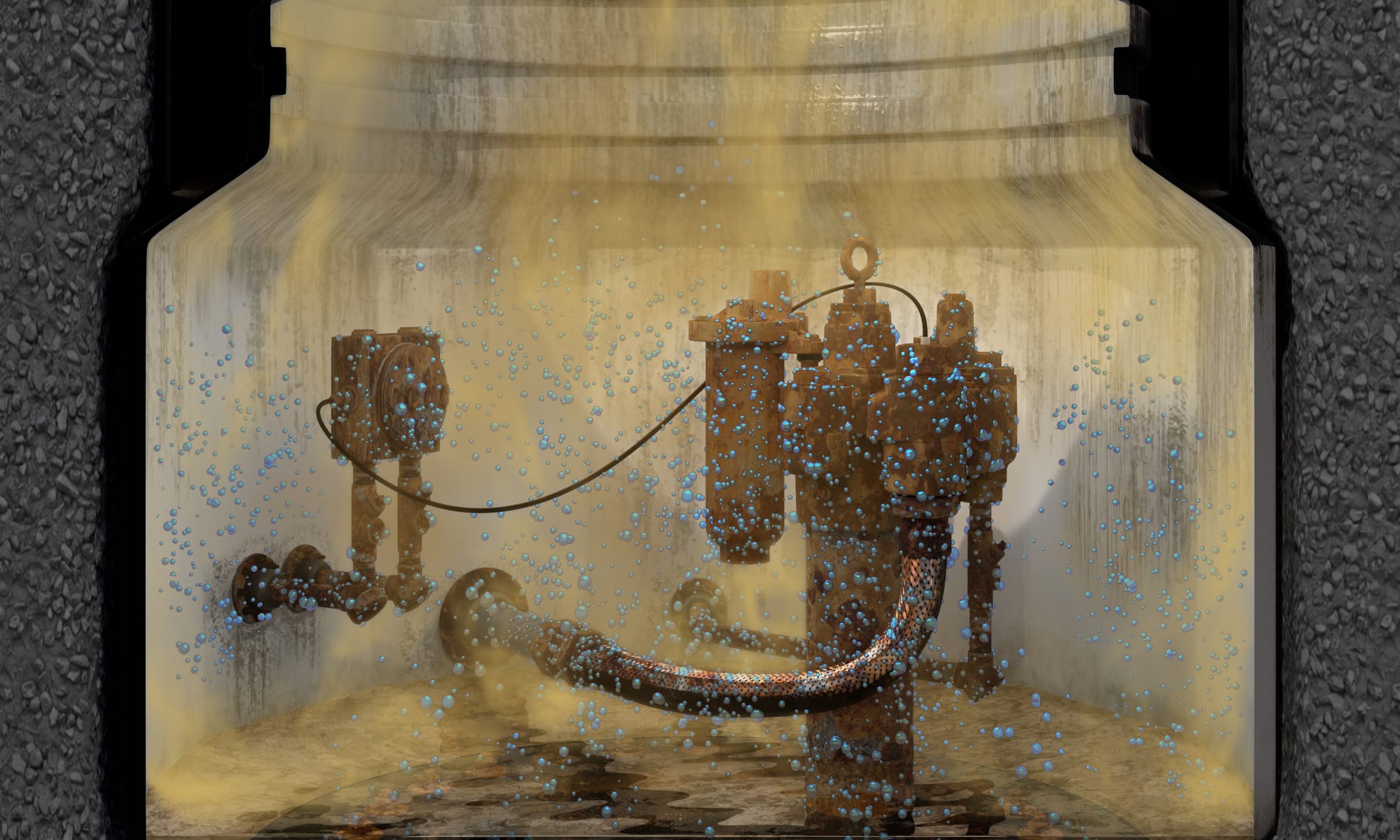

The Red Armor® STP

The Red Armor Submersible Turbine Pump has an additional 30% increase in stainless steel hardware from The Red Jacket AG STP. It has all the advantages of the Red Jacket Submersible Turbine Pump design but was constructed specifically to withstand corrosive environments.

The Red Armor STP is compatible with the same fuel types as The Red Jacket AG STP, but also protects against:

- Microbial Growth in Tank (Ultra-low Sulfur Diesel)

- Constant Moisture Presence or Water Ingress into Sump

- Known Corrosive Environment