The Influence of Microbial Growth

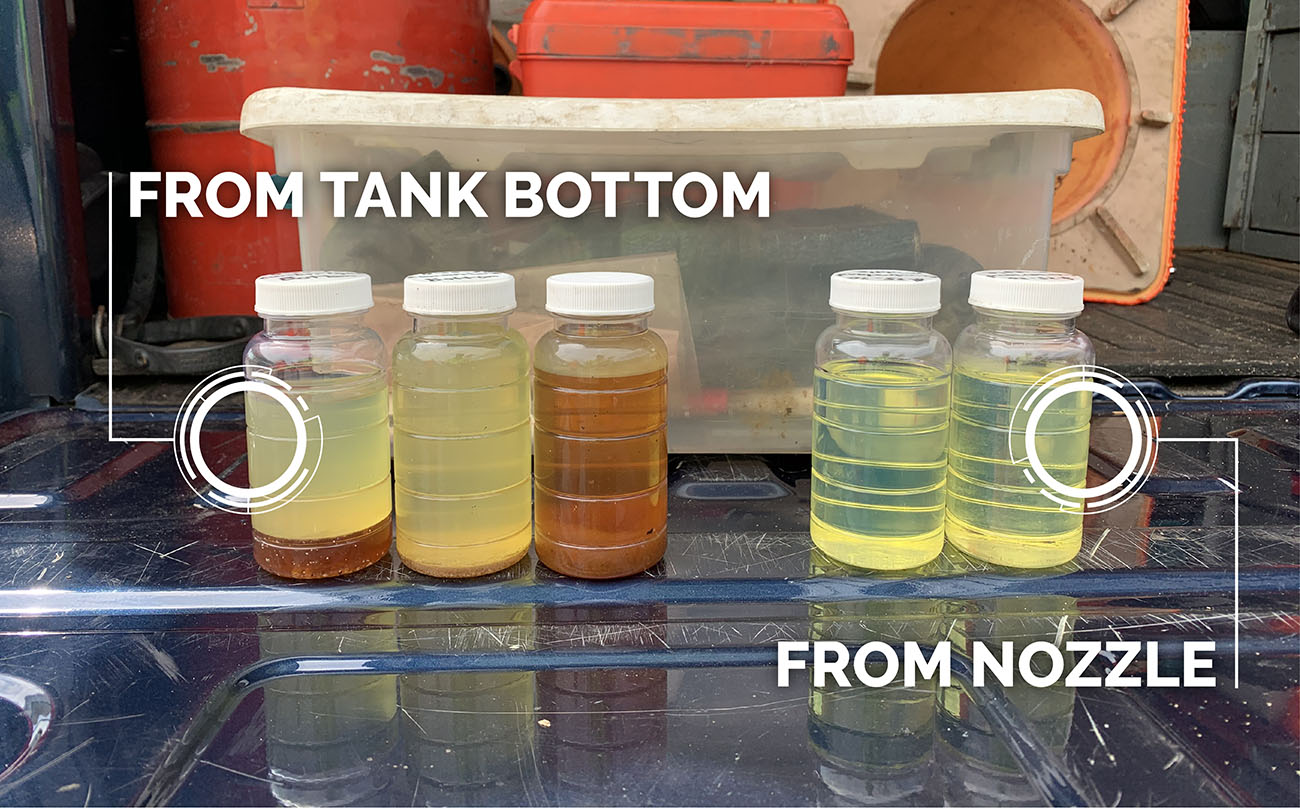

Once these microorganisms are present in a fueling system, they can degrade the quality of the fuel which can lead to plugged filters or even pump and injector problems for customers. Equipment corrosion is also an expensive problem for gas station operators since it often results in unplanned downtime and increased maintenance costs.

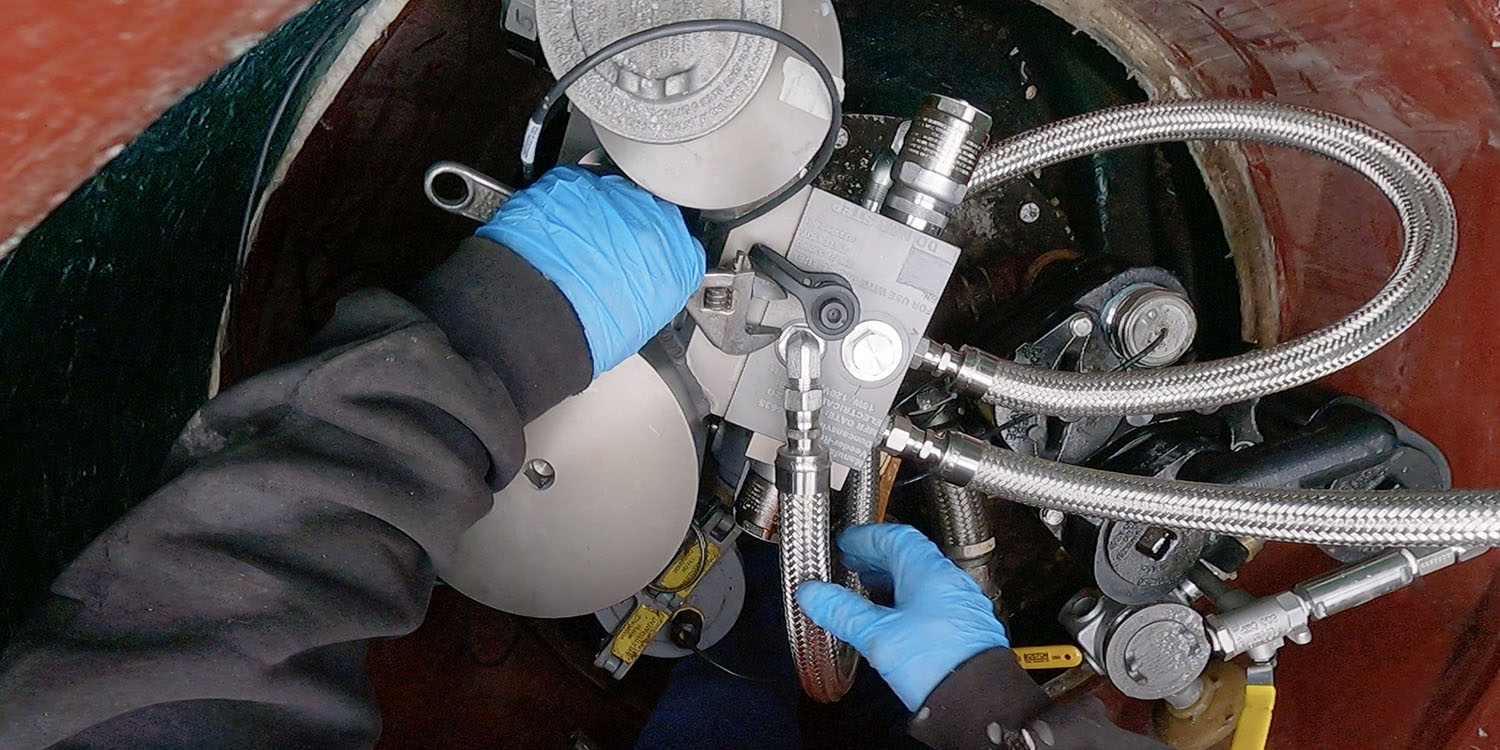

For this reason, it’s important that gas station operators monitor their sites for signs of corrosion and, once identified, take steps to mitigate corrosion before it negatively impacts their business.

Learn more about indicators of corrosion

Read all our Combat Corrosion Articles

Water is integral to corrosive environments and a serious threat to diesel storage tanks and fuel equipment health. Learn more about the cause and impact of corrosion, and steps you can take to mitigate it.

Read More