Additional Tank Maintenance

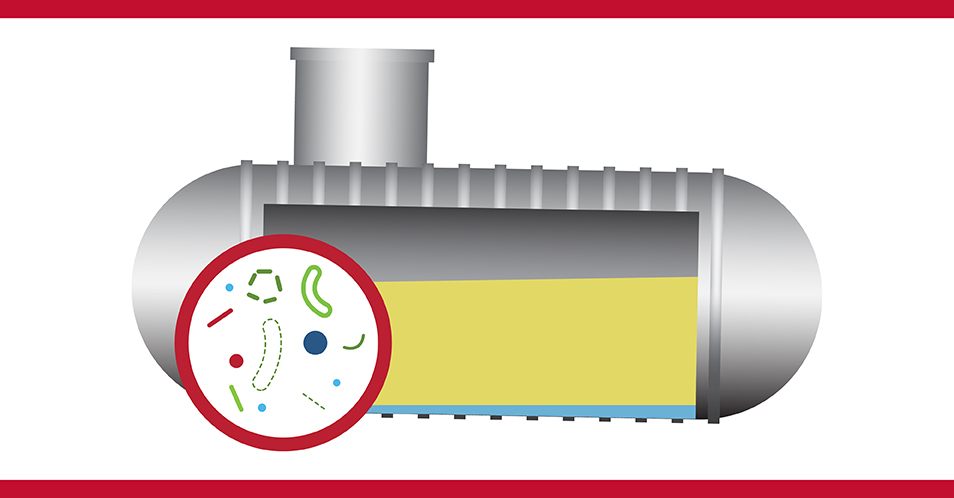

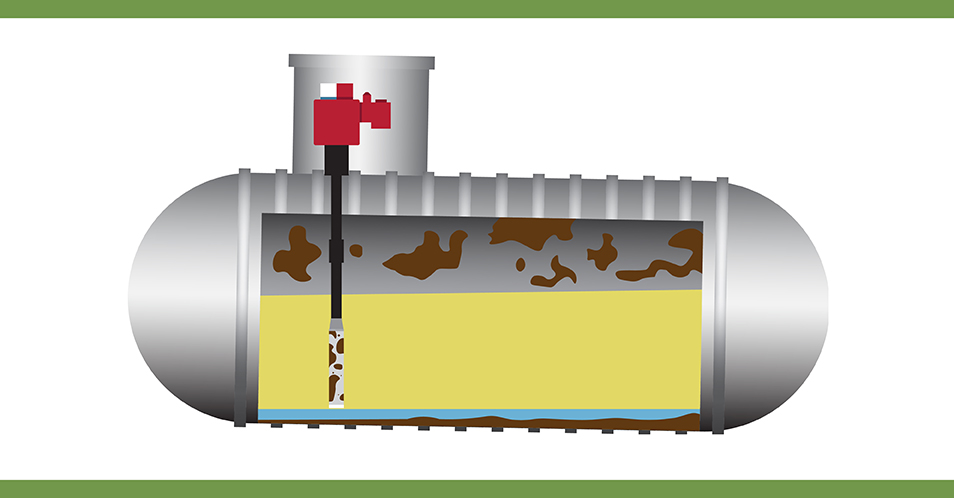

Water is the chief enemy of diesel tanks as stagnate water will breed microbial growth. Traditional water removal and tank cleaning methods are costly and time consuming. And, while these methods will initially clean your tank, they provide no assurance that there will not be water within the tank shortly after the cleaning takes place. As water enters your tank again through fuel deliveries, leaky seals, and the like, additional cleanings will be necessary in the future.

Maintaining a diesel storage tank and ensuring that the environment within it is not conducive to corrosion carries a cost of around $6,000* annually when the additional tank cleanings and down time are considered.

Equipment Life Penalty

As microbial growth attacks your fueling equipment, the corrosion can cause improper operation or failure in your fueling systems. Corrosion can frequently accelerate equipment aging and increase the need to reinvest in fueling equipment. Clogged filters, deterioration of seals and gaskets, premature failure of meters, malfunction of sensors and/or probes, and corrosion affecting the integrity of STP components, riser pipes, and tanks are all common results of corrosion.

By some estimates, corrosion may accelerate equipment aging by up to five times, reducing your equipment life and costing gas station operators $10,000* per year.

Lower Flow at the Nozzle

One of the tell-tale signs of microbial growth contamination is an increase in the particulate that in turn clogs dispenser filters. In order to maintain higher throughputs at the pump, the gas station operator needs to change out their filters more frequently. However, because of the cost associated with the filter changes, many gas station operators will wait until throughput is reduced by more than 10%. That reduction in fuel flow affects the rate at which customers are being served, especially during peak hours.

This slow flow at the dispenser translates to $15,000* in lost profit and can keep a station from getting repeat business. Frustrated customers end up driving away and do not stop for in-store purchases either.

Maintain Equipment Integrity

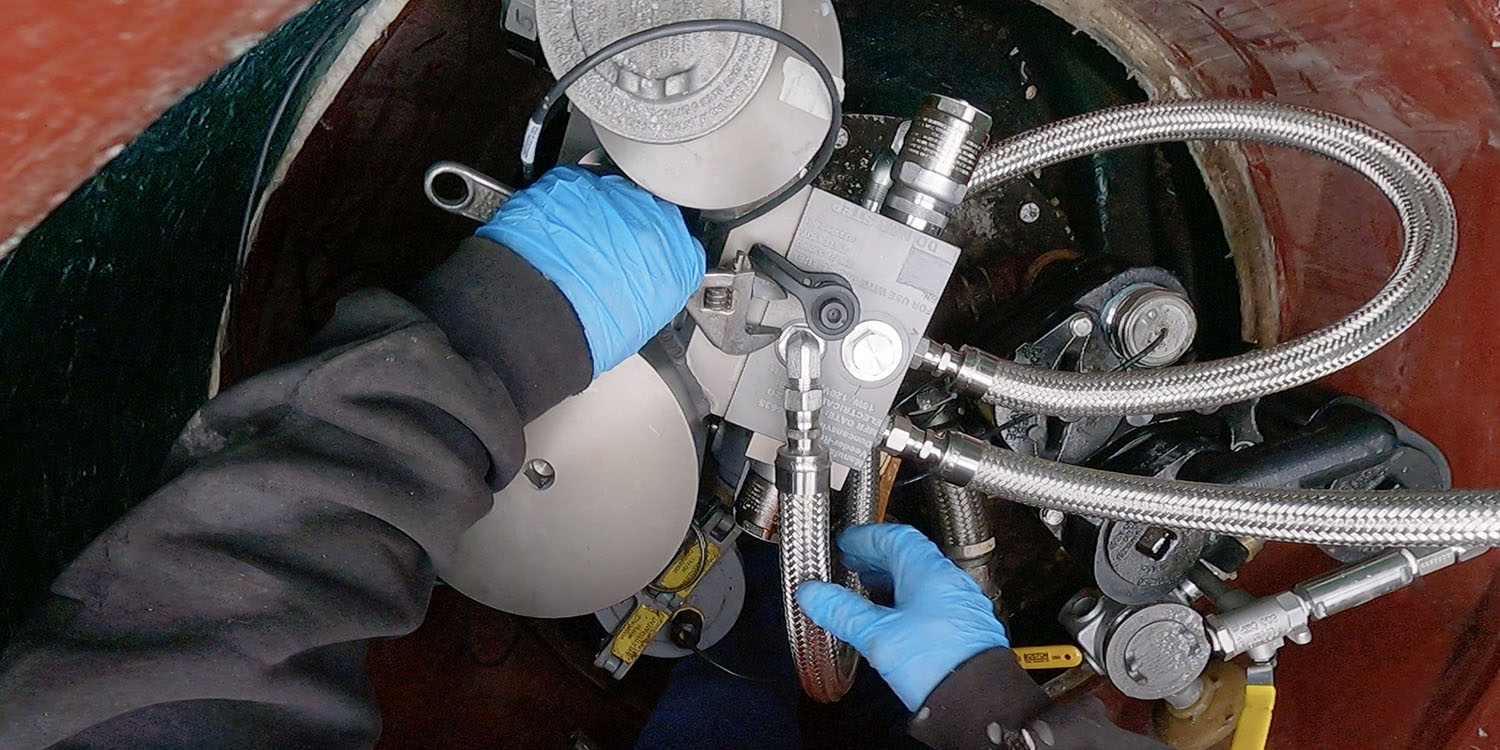

The HydrX Fuel Conditioning System combats in-tank corrosion by providing continuous water removal within diesel underground storage tanks. Adding it to your fueling systems keeps your fuel within specification and maintains equipment at peak efficiency to avoid unplanned shutdowns.

* ROI estimates vary based on site conditions

Read all our Combat Corrosion Articles

Water is integral to corrosive environments and a serious threat to diesel storage tanks and fuel equipment health. Learn more about the cause and impact of corrosion, and steps you can take to mitigate it.

Read More