Provide Insight to Your Fueling Operations

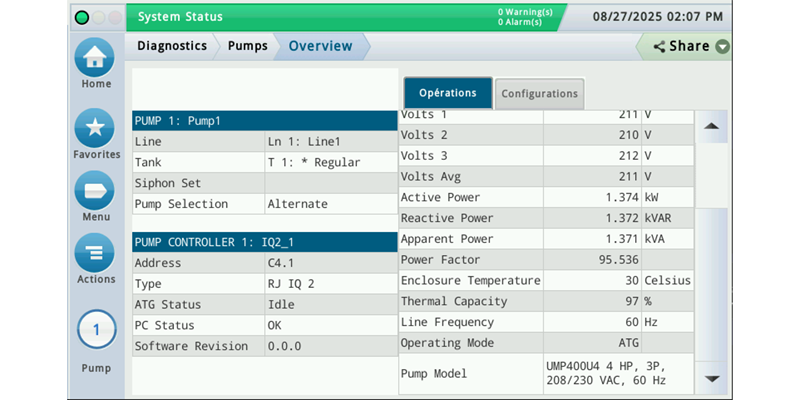

Intelligent Pump Control (IPC) enables the TLS-450PLUS Automatic Tank Gauge (ATG) to connect with the IQ2 Smart Controller, delivering real-time Submersible Turbine Pump (STP) status, reports, statistics, and electrical parameter information. The real-time pump status feature displays current, voltage, power consumption, and flow helper mode, allowing for enhanced monitoring. IPC also supports remote control and troubleshooting to optimize your fueling operations.

The TLS-450PLUS ATG

Provides the most comprehensive site data for advanced fuel asset management, including real-time updates and alerts on dispense modes, manifolding, communication, and system faults.

The Red Jacket® Smart STP Controller

Contains the intelligent circuitry that allows the communication path to flow between the ATG and STP, providing key data to support informed business decisions.

The Red Jacket Fixed Speed STP

Optimizes the fueling process and provides real-time performance data. IPC Software with Red Jacket Diagnostics empowers delivers the data needed for effective site operation.

Remote Diagnostics & Control

IPC supports the following categories of diagnostics for each STP Controller:

- Current Operational Status – Provides real-time pump operational status warnings and alarms

- Pump Electrical Parameter – Indicates other vital STP electrical system data

- Pump Statistics and Activity Log – Tracks and records pump and motor parameters to support troubleshooting

Functionality

- Advanced Pump Control – Utilizes TLS Dispense Modes

- Line and Pump Priority – Determines which pump or line to activate based on tank and pump feedback

- Staging (Helper Mode)

- Primary – Secondary

- Alternate

- In-Tank Staging

- Across Tank Staging

- Flow Optimization

- Utilizes pump staging to optimize consistent delivery of product at the nozzle (Helper Mode)

- Switch on the Fly – Provides continuous line pressure during staging from pump to pump

- Operational Redundancy

- Utilizes TLS-based logic to understand when one pump needs the assistance of another pump

- Automatic Events for Alarm and Email Notification

- Through the TLS-450PLUS ATG

Dispense Modes

- Sequential – The Sequential dispense mode selects a tank based on tank numbers (lowest number tank used first). Fuel is pumped from the initial tank until a certain low product level is reached (e.g., “pump threshold %” of volume) before moving to the next tank.

- Alternate by Height or by Volume – The system will try to keep the products in the tanks level based on volume or height. Alternate by Volume is suggested when there are multiple sized tanks connected to the line.

- Alternate by Pump – Pump selection is based purely on pump sequence. In this mode, tank selection is ignored. Pumps are engaged in pump number order. For each new hook-signal, the next pump in sequence is engaged (e.g., P1, P2, P3, P1…).

- Priority – Based on tank and flow rate information.

Equipment Compatibility

Red Jacket IQ2 Smart Controller: 0411075-001

- TLS-450PLUS with IPC/Red Jacket Diagnostic Enhancement

Integration Solution for 3rd Party Pump Controllers

The TLS-450PLUS ATG can also monitor and control Non-Red Jacket submersible pump controller/pump sets with IPC.

- Receive communication alarms from the pump controller/STP when issues arise for immediate action

- Use data to better understand STP performance and needed maintenance measures

- Proactively service equipment to ensure maximum uptime IPC allows the TLS-450PLUS ATG to display and report STP activity through a direct communication link between a STP pump controller and the TLS-450PLUS ATG via an RS-485 connection.

Documents

- Intelligent Pump Control Sell Sheet (576047-338)

- The Red Jacket IQ2 Smart Controller & IQ Control Box Specifications Sheet (576047-597)

- Red Jacket IQ Control Box Datasheet (576047-234)

- Red Jacket Product Guide (576047-310)

- Red Jacket Intelligent Pump Control Installation Checklist (576047-499)

- IQ Control Box Installation and Owner's Manual (051-330)