The HydrX Fuel Conditioning System

The Veeder-Root HydrX Fuel Conditioning System combats in-tank corrosion by providing continuous water removal within diesel storage tanks. The unique design of HydrX removes water from the lowest point in the tank, preventing water from stagnating on the tank bottom and breeding microbial contaminants. The integrated filtration removes entrained water, rust, sand, and microbial particulate from the fuel, polishing it before returning clean fuel back to the tank.

The primary components of the HydrX Fuel Conditioning System are:

- Fuel Conditioner Kit

- Fuel Conditioner

- Valve Conduit Kit

- WID Riser

- HydrX Software Feature Enhancement

- Water Drain Kit

- Water Intake Device

- Guide Tube

- Installation Kit

Fuel Conditioner Kits

The Fuel Conditioner Kits simplify the ordering process by combining all standard components into a single orderable part number. There is one Fuel Conditioner Kit for each model (HydrX 250D and HydrX 500D).

HydrX 250D Fuel Conditioner Kit (P/N 0342909-325)

| Component Part Number | Component Description |

| 0860580-025 | Fuel Conditioner (2.5-gallon waste water capacity) |

| 0330020-901 | Kit – WID Riser – 8.75” Length |

| 0330020-885 | Kit – Valve Conduit |

| 0332972-032 | HydrX Software Feature Enhancement |

| 0330020-880 | Kit – Water Drain |

HydrX 500D Fuel Conditioner Kit (P/N 0342909-350)

| Component Part Number | Component Description | |

| 0860580-050 | Fuel Conditioner (5-gallon waste water capacity) | |

| 0330020-867 | Kit – WID Riser – 15.5" Length | |

| 0330020-885 | Kit – Valve Conduit | |

| 0332972-032 | HydrX Software Feature Enhancement | |

| 0330020-880 | Kit – Water Drain |

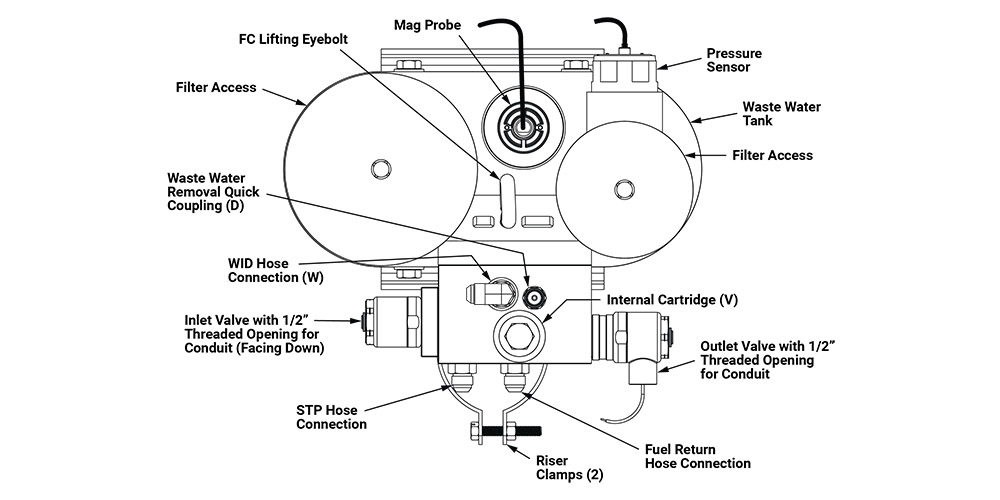

Fuel Conditioner

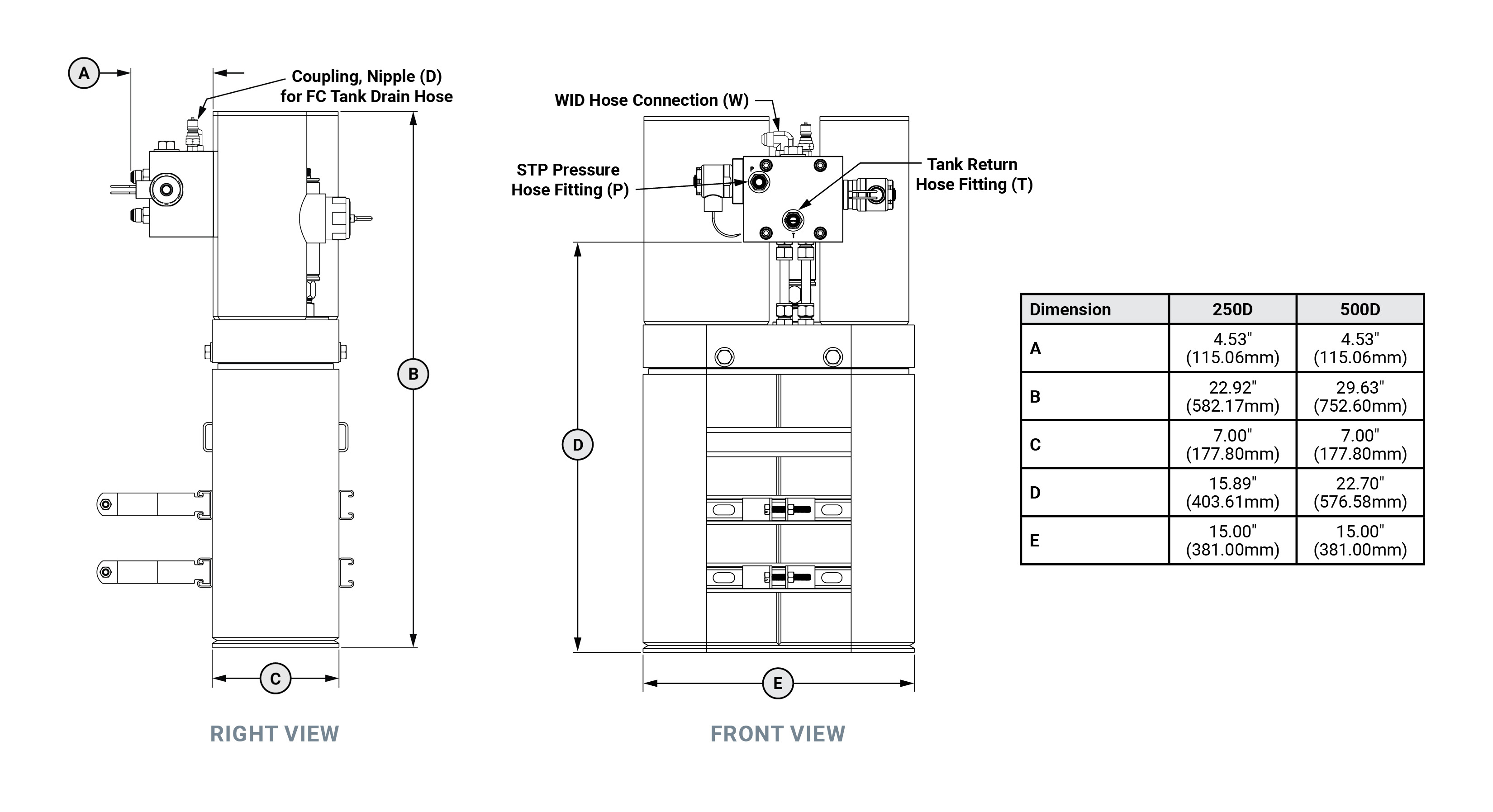

The Fuel Conditioner is a fully integrated system that effectively removes water and maintains fuel cleanliness. The Fuel Conditioner is offered in two models that allows end users to maximize water capacity when the required space is available inside the sump. HydrX 250D has a 2.5-gallon capacity and with a height of 23” is sized for medium bury depth sumps. HydrX 500D has a 5-gallon capacity and with a height of 30” is sized for deep bury depth sumps.

Each Fuel Conditioner model includes two automatic solenoid valves that control the flow of water removed from the bottom of the diesel storage tank and the flow of clean fuel returned back to the tank. Integrated sensors enable predictable maintenance for the site operator. There are two filters installed in the Fuel Conditioner housing. The inlet filter is a two-stage, particle and coalescing type filter. The outlet filter is a single stage, fine water separating element that provides a fine polish for optimal fuel quality.

| Part Number | Description |

| 0860580-025 | Fuel Conditioner (2.5-gallon waste water capacity) |

| 0860580-050 | Fuel Conditioner (5-gallon waste water capacity) |

Valve Conduit Kit

The Valve Conduit Kit provides the necessary conduit connection for the 120VAC inlet and outlet solenoid valves. The kit is comprised of a junction box, nipples, hard elbow, and explosion proof union.

| Part Number | Description |

| 0330020-885 | Kit – Valve Conduit |

WID Riser

The WID Riser is a 4” stainless steel riser with a custom flange that provides a mounting location for the Guide Tube. The WID Riser is available in two lengths that are specific to the Fuel Conditioner models.

| Part Number | Description |

| 0330020-901 | Kit – WID Riser – 8.75" (HydrX 250D) |

| 0330020-867 | Kit – WID Riser – 15.5" (HydrX 500D) |

Water Drain Kit

Water drain is an essential maintenance function and required for system operation. The HydrX Water Drain Kit integrates with quick connect fittings on top of the manifold. It is a complete hose assembly that allows the user to drain water from the Fuel Conditioner.

| Part Number | Description |

| 0330020-880 | Kit – Water Drain |

Variable Components

The following components, combined with a Fuel Conditioner Kit, complete the HydrX Fuel Conditioning System. Application information is required in order to properly size this hardware. Reference the HydrX Fuel Conditioning System Site Inspection Guide (576047-355) for additional information.

- Water Intake Device

- Guide Tube

- Installation Kit

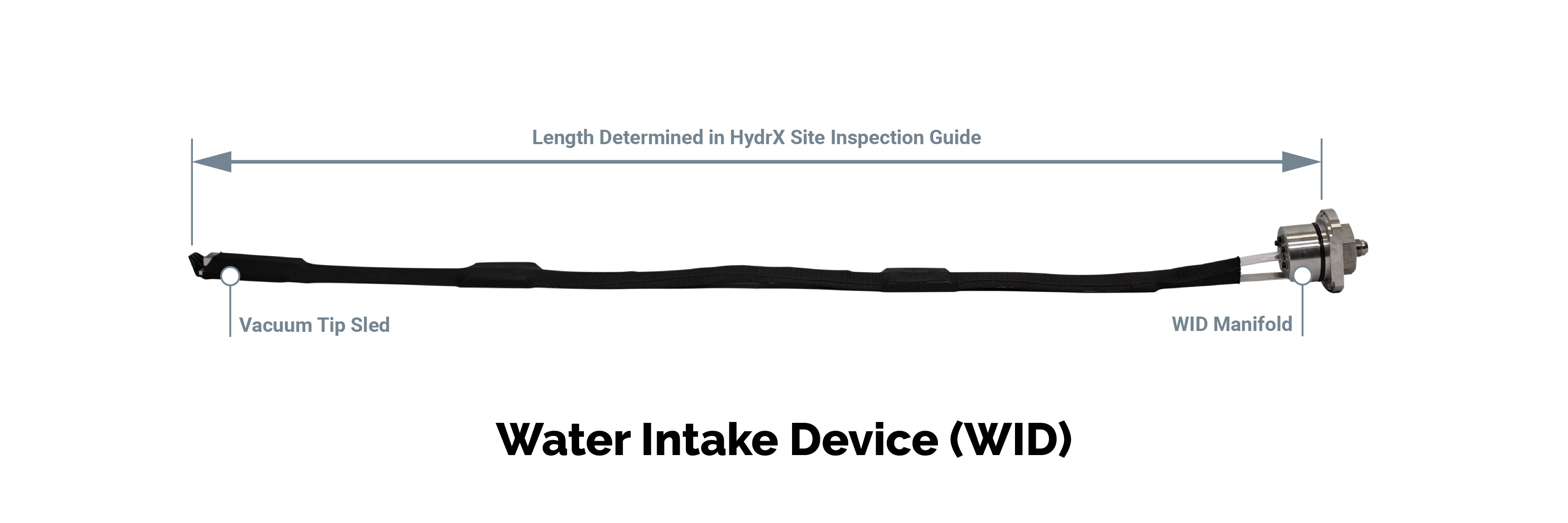

Water Intake Device (WID)

The WID is a flexible device that extends along the tank bottom to the lowest point of the tank. It operates in multiple modes and is powered by the Submersible Turbine Pump (STP) to circulate fluids through the Fuel Conditioner in the sump.

- Vacuum mode uses suction from the STP port to pull fuel, water, and particulate into the fuel conditioning system. While customers are dispensing fuel, Vacuum mode is operating to pull water and particulate from the tank bottom.

- Sweep mode uses clean fuel to push water and particulate to the lowest point in the tank, where it is then extracted using vacuum mode. Sweep mode is activated during a fuel delivery and during a scheduled autocycle.

- Polishing mode is activated during a delivery and at the end of an autocycle when the vacuum and sweep modes are complete. This mode provides a fine polish for optimal fuel quality.

The WID is sized specific to the conditions of the installation. Factors that determine WID length are: HydrX model, tank size, tank tilt, and WID Riser install location.

| Part Number | Description |

| 08608XX-XXX | Water Intake Device (WID) |

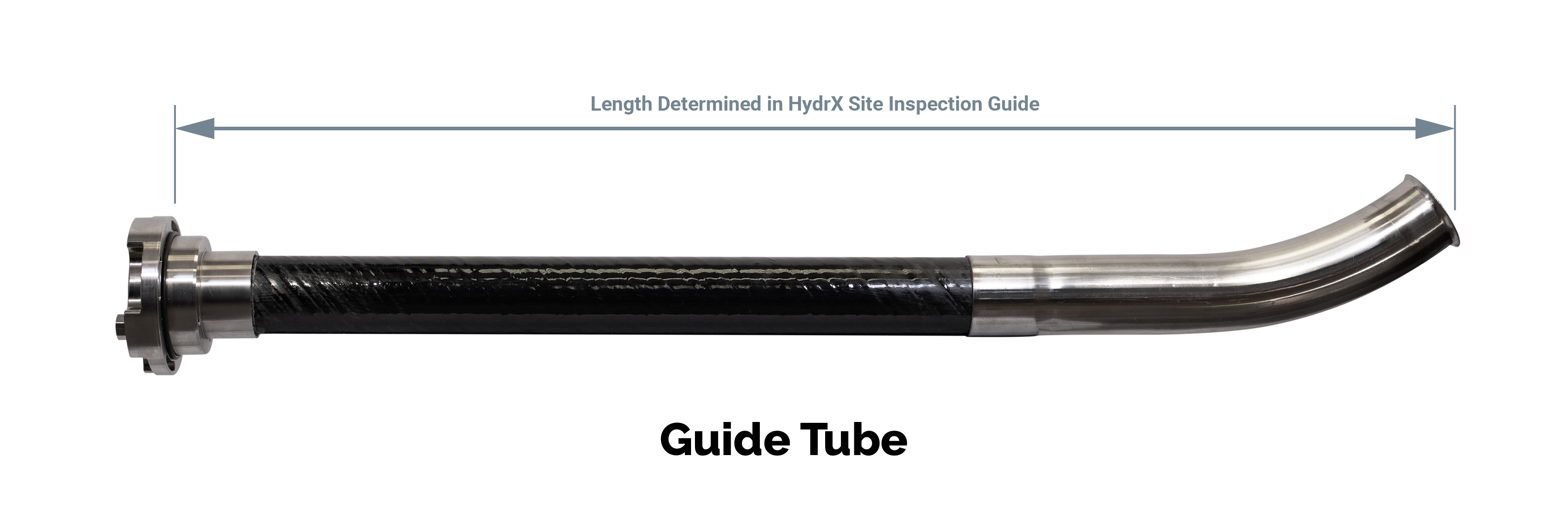

Guide Tube

The Guide Tube is a reinforced composite tube that extends vertically into the tank below the Fuel Conditioner through the WID Riser. The Guide Tube is used for mounting and precise orientation for the WID. A stainless steel elbow at the distal end guides the WID along the tank bottom. Guide Tubes are produced in 6” increments from 50” – 164” to support tank diameters between 4’ (48″) and 12′ (144″).

| Part Number | Description | Overall Length |

| 0860780-XXX | Guide Tube | 50" (P/N 0860780-050) – 164" (P/N 0860780-164) |

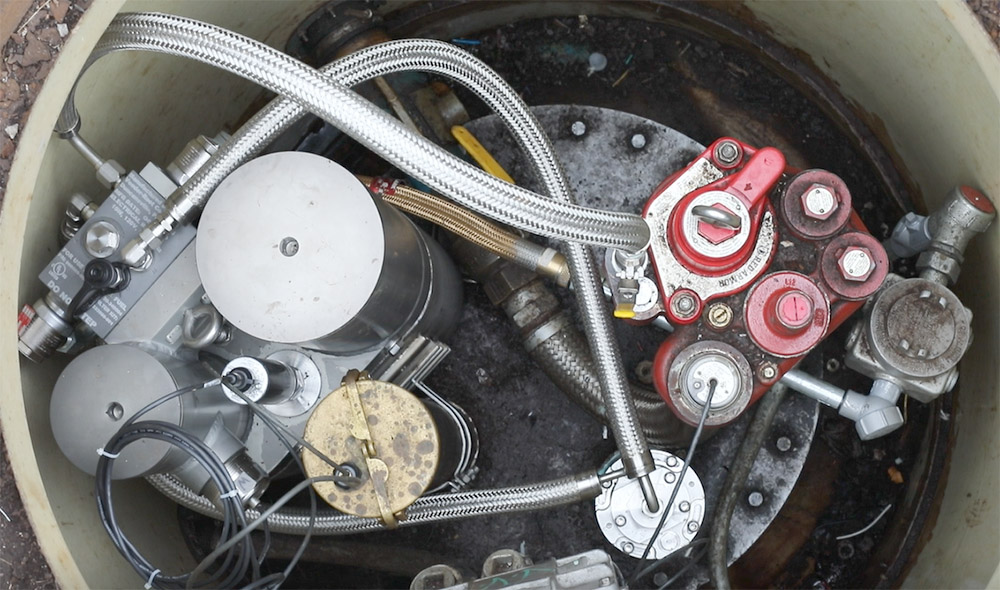

Installation Kits

Select your Installation Kit option based on who the STP manufacturer is that HydrX will be installed with. Each kit includes a pressure port adaptor assembly, braided stainless steel hoses, and Flaretite seals. One kit is required for each Fuel Conditioner.

| Part Number | Description |

| 0330020-875 | Kit – TRJ Installation |

| 0330020-874 | Kit – FE Petro® Installation |

Not shown in Kit images: ¼-20 Hex Head Screw, Nylon Tie Wrap, Epoxy Sealing Pack, 3/8 JIC to SAE Adapter, Anti-seize Compound.

HydrX System Specifications

| Component Approvals |

Solenoid Valve: UL Approved |

| Fuel Conditioner External Dimensions 250D | 23″ (H) x 15″ (W) x 12″ (D) |

| Fuel Conditioner External Dimensions 500D | 30″ (H) x 15″ (W) x 12″ (D) |

| Operating Temperature | -4°F (-20°C) to 122°F (50°C) |

| Storage Temperature | -40°F (-40°C) to 158°F (70°C) |

| Installation Location | STP Sump and Diesel Storage Tank |

| Relative Humidity | 0-100% (Condensing) |

| HydrX Solenoid Valve Power Requirements (to the sump) |

AC Power Wiring carrying 120 VAC control circuit to power solenoid valves on a separate breaker. Local electrical codes or site requirements may also require a separate Emergency Stop Control. Minimum wire size shall be 14 AWG. 5 wires total: 2 wires for valve control voltage, 2 neutral wires, and 1 ground wire. |

| HydrX Sensor Wiring Requirements | 1. Wire Type – Shielded cable required regardless of conduit material or application. Shielded cable must be rated less than 100 picofarad per foot manufactured with a suitable material such as Carol C2534 or Belden 88760, 8760, or 8770. 2. Wire Length – Maximum 1,000 ft to meet intrinsic safety requirements. Improper system operation could result for runs over 1,000 ft. 3. Wire Gauges – Color coded – shielded cable used in all installations. Wires should be #14 - #18 AWG stranded copper wire and installed as Class 2 circuits. As an alternate method when approved by the local authority having jurisdiction, #22 AWG wire such as Belden 88761 may be suitable with the following requirements: Wire run is less than 750 ft; Capacitance does not exceed 100 pF/ft; Inductance does not exceed 0.2 uH/ft. |

| Waste Water Capacity | 2.5 gallons (HydrX 250D) or 5 gallons (HydrX 500D) |

| Filtration | 25 microns |

| Water Removal | Multi-port water removal throughout the tank bottom and from the lowest point in the tank. |

| Intelligent Operation | Pump utilization is optimized based on water removal. HydrX gives the user complete control over how much time is allotted per day to polish the fuel. Logic is built-in to prevent freezing under extreme temperature conditions. |

System Construction

| Fuel Conditioner | |

| Lifting Eyebolt | Stainless Steel |

| Waste Water Tank | Stainless Steel |

| Water Removal Fitting | Stainless Steel |

| WID Hose Connection | Stainless Steel |

| Filter Housing & Access Caps | Anodized Aluminum |

| Solenoid Manifold | Anodized Aluminum |

| Guide Tube | |

| Elbow | Stainless Steel |

| Guide Tube Flange | Stainless Steel |

| Tube | Fiberglass Reinforced Composite |

| Water Intake Device (WID) | |

| Body | Stainless Steel |

| Fittings | Stainless Steel |

| Vacuum Tip Sled | Stainless Steel |

| WID Manifold | Stainless Steel |

| Intake Lines | Fluorinated Ethylene Propylene (FEP) |

| Sleeve | Polyethylene / Polyester |

FE Petro® is a registered trademark of Franklin Electric Company, Inc.