Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

In the realm of retail fueling operations, the efficiency of Submersible Turbine Pumps (STPs) is critical. To help determine STP efficiency, Veeder-Root has conducted an analysis that assesses the performance and energy consumption of fixed speed versus variable speed STPs.

Technical Evaluation of Fixed Speed STPs

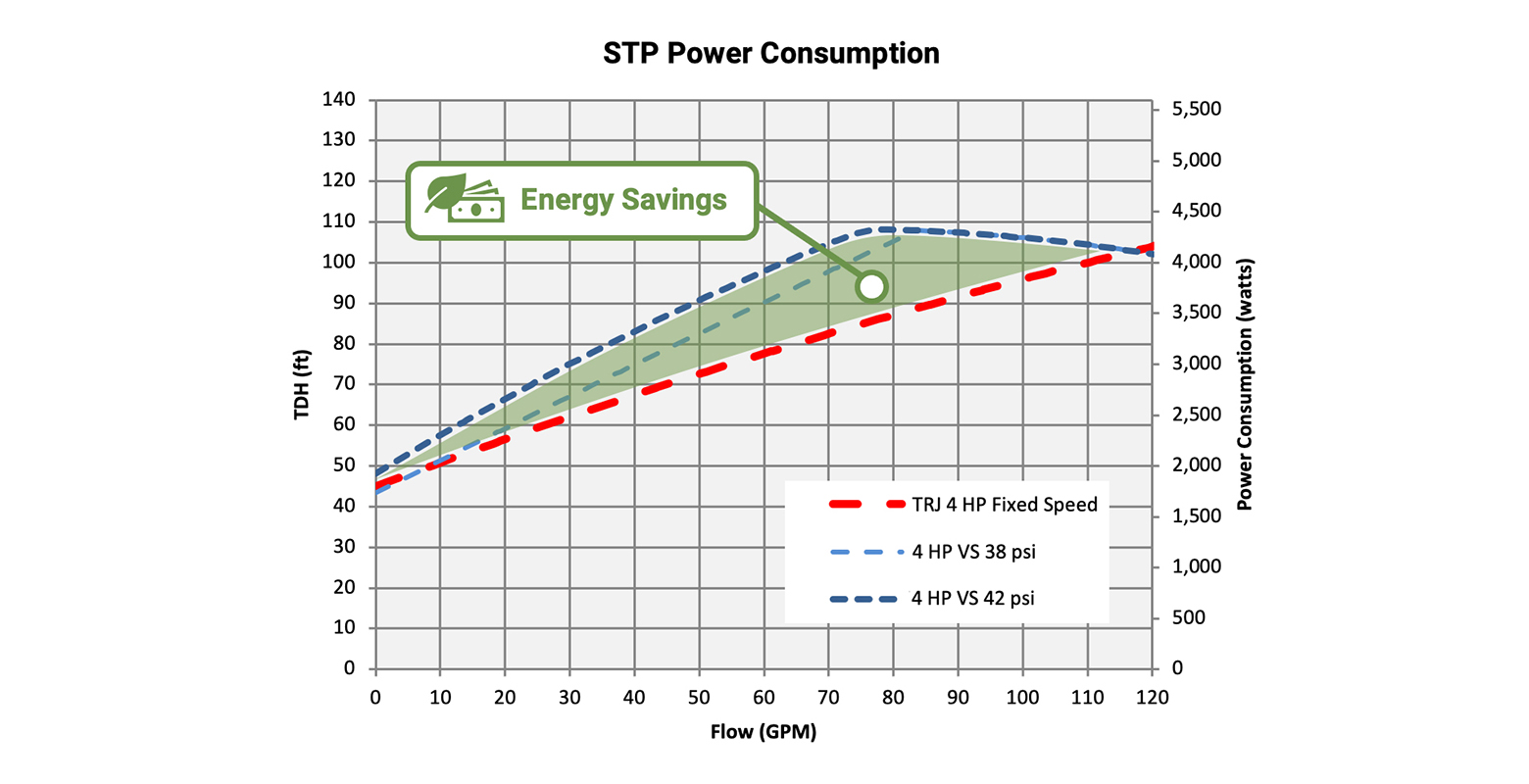

A controlled test environment was established to simulate standard retail fueling conditions. The Red Jacket® 4 HP Fixed Speed STP was evaluated alongside equivalent variable speed models. Each STP type was connected to a representative fuel dispenser and a simulated proportional valve designed to regulate flow at the nozzle. The test protocol involved running each pump at various flow rates to mimic the range of real-world operating conditions. The variable speed STP was evaluated at 38 and 42 PSI. To monitor power consumption, a meter was connected at the power input to the STP controller.

Findings on Energy Efficiency

The hypothesis that variable speed STPs offer better energy savings was not supported by the test outcomes. In all the scenarios examined, the energy efficiency of variable speed pumps did not surpass that of the fixed speed pumps.

The results indicated that the fixed speed STP demonstrated a 4% increase in energy efficiency when compared to the variable speed counterparts at matched flow rates. The 4 HP variable speed consumes up to 730 watts more to pump 1,000 gallons; assuming a typical retail site with a 4 HP STP dispensing 500,000 gallons per month and the cost per kilowatt hour of $0.17, the retailer saves $250 per year per STP with The Red Jacket 4 HP STP.

Variable frequency controllers regulate power by converting AC power to DC using a rectifier. The DC power is smoothed out and then converted back to AC power using an inverter. The newly converted AC power can have a variable frequency and voltage, which in turn controls the motor speed. While converting AC to DC and then back to AC, the inefficiencies of those conversions translate to power loss and are prone to failure. As a result, the benefits of variable speed technology do not translate effectively in the specific context of retail fueling operations. Whereas the fixed speed controllers apply constant AC power, so the losses are minimized and provide equivalent flow performance consuming less power.

The Bottom Line

This analysis challenges the prevailing notion that variable speed STPs are more energy-efficient than fixed speed pumps. This finding highlights the potential for significant power consumption savings, debunking the myth of variable speed superiority in retail fueling operations. The Red Jacket STPs are designed to run at optimal speed thereby running efficiently and prolonging their useful life.