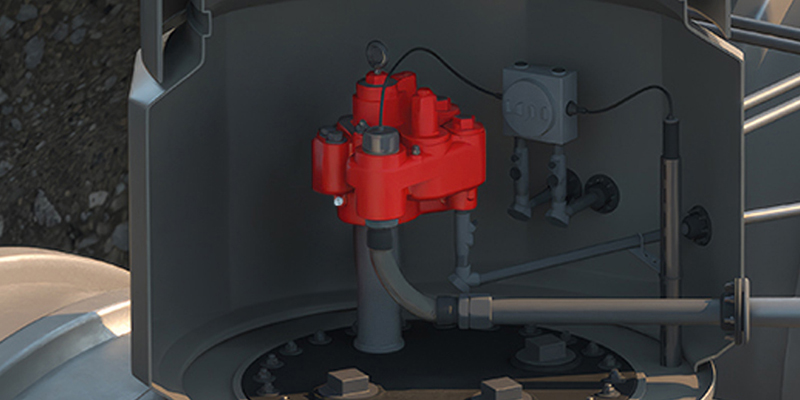

The Red Armor® STP

The ultimate survivor in your fueling infrastructure, the Red Armor series of submersible turbine pumps is built to last in the harshest corrosive environments created by ULSD and ethanol blends.

Advancing the Red Jacket® Platform

All the advantages of the Red Jacket Submersible Turbine Pump, and now designed to withstand corrosive environments. Whether your site is struggling with Ethanol-induced in-sump corrosion or ULSD-induced in-tank corrosion, with its specialty coating* and stainless-steel construction, the Red Armor solution is designed to survive.

Red Armor is a robust fixed-speed fuel pump with a motor that delivers higher flow rates than comparable submersible fuel motors for corrosive environments, promoting optimal fuel flow and dispensing. The Red Armor STP also features Red Jacket’s advanced packer manifold design, making it the industry’s easiest and safest STP to install and service. This STP solution is available in ¾ HP to 4 HP motor configurations and fixed or Quick Set® adjustable lengths.

*Red Armor’s specialty coating is the toughest performer across a battery of abrasion, immersion and impact standards.

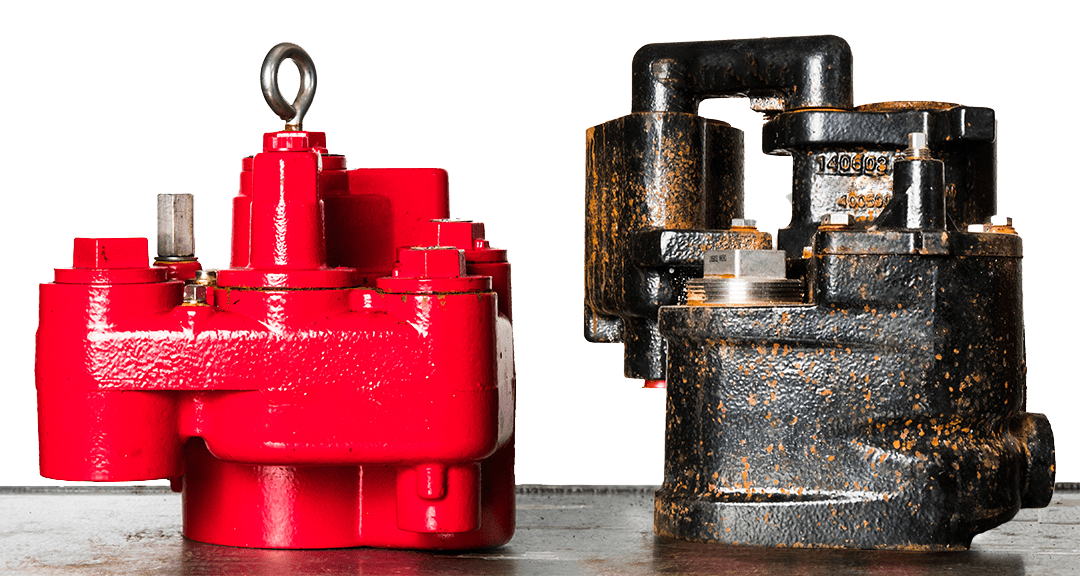

See the Red Armor® Difference

Features and Benefits

The Red Armor family of Submersible Turbine Pumps (STPs) and Pump Controllers ensure that your customers can pump fuel quickly, efficiently and safely – whether it’s motor fuel, diesel, aviation gasoline, ethanol/methanol or kerosene – in even the harshest aboveground or underground fueling environments.

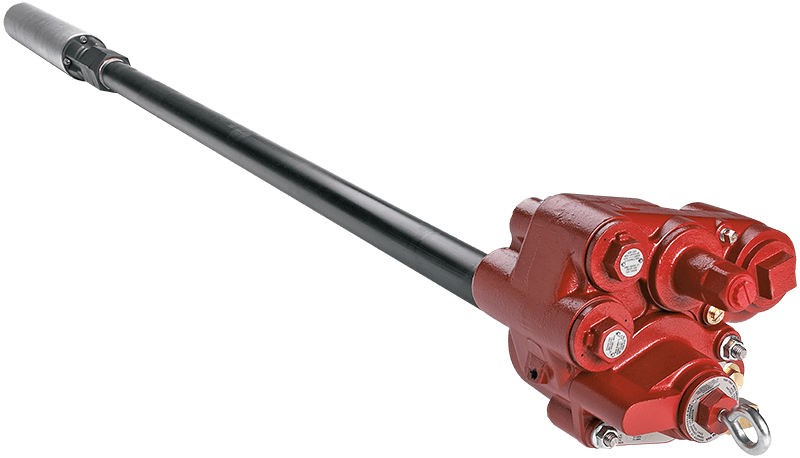

In-sump Protection from Corrosion

Added protection on all exposed surfaces

- Specialty coating on all cast surfaces withstands acetic acid exposure to prevent pitting and deterioration over time.

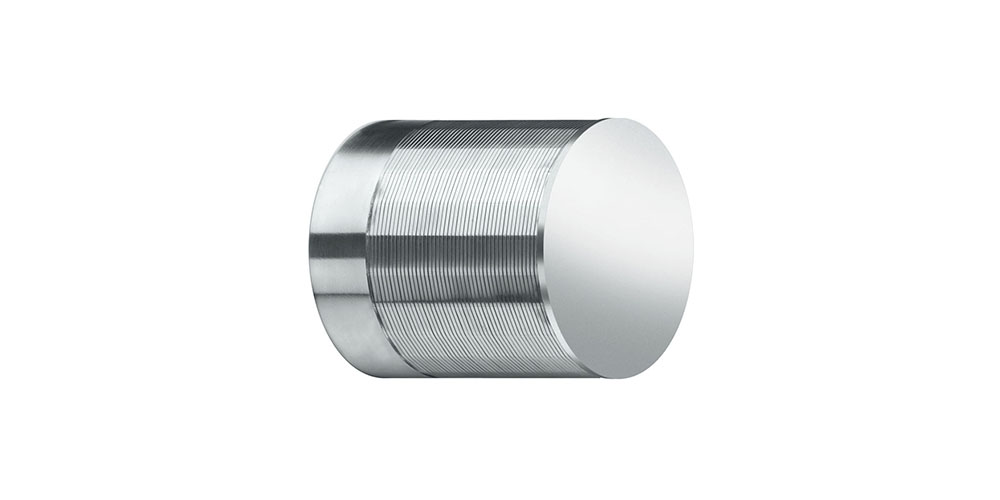

- Stainless Steel construction on all exposed surfaces ensures easy maintenance for the life of the pump, including; riser, nuts, springs, screws, check valve seat, eye bolt, and check valve guide.

All the advantages of The Red Jacket Packer Manifold design

- Built-in Isolated Contractor’s Box

- Easy to Install and Service

- Increased Electrical Safety

- Environmentally Friendly

- Innovative Check Valve Design

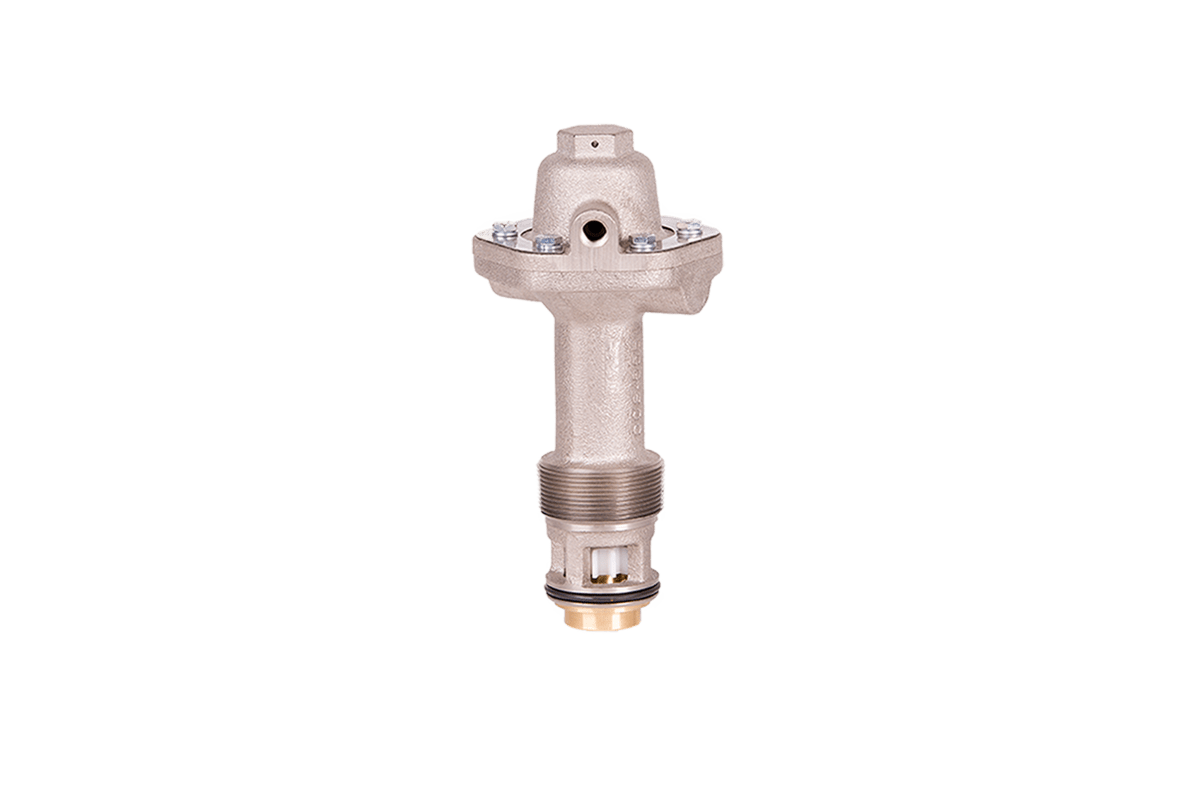

In-tank Protection from Corrosion

Prevent corrosion

- Constructed with upgraded materials - Powder-coated discharge head, stainless column pipe and quick-set connector.

All the advantages of The Red Jacket UMP design:

- Up to 5% Increased Flow with 8% Less Power Consumption

- Improved Reliability and Increased Safety

- Better Quality

- Universal Compatibility

Build a System that Prevents Corrosion

As corrosion advances it has the potential to affect the integrity of piping and electrical systems, and the serviceability of submersible turbine pump equipment. Veeder-Root has developed The Red Armor STP and accessories, to help users create the right configuration for preventing corrosion in their fueling environment.

Learn more about the causes of corrosion and the equipment needed in your fueling system to help prevent it.

Learn more about in-sump corrosionSpecifications

Fuel Compatibility |

Protects against:

|

Motor Sizing |

|

Hardware Construction | Column Pipe and Riser:

Packer Components:

|

Protective Coatings |

|

Operation Environment |

|

Installation Depth Range | Fixed Length

Quick Set (Adjustable Length)

*Assumes 1.5 HP |

Packer Manifold Access Ports | Siphon Ports:

Line Pressure Port:

Vent Port:

|

Check Valve Compatibility |

|

Agency | UL/cUL Listings:

|

The Red Jacket Portfolio offers a variety of solutions tailored for the special requirements of resiliency in today’s renewable fuels, as well as fuels focused on improved emissions and fuel economy.

Documents

- Combat In-Sump Corrosion Flyer

- Red Armor STP Built to Combat Corrosion (576047-340)

- Red Jacket Red Armor STP Specification Sheet (576047-272)

- Red Jacket STP Fuel Compatibility (576047-305)

- Red Jacket Fixed Speed Reliability Sheet (576047-331)

- Red Jacket Stainless Steel Riser Pipe Data Sheet (576047-279)

- The Red Jacket STP Flow Quick Reference Guide (576047-523)

- Red Jacket Product Guide (576047-310)

- Veeder-Root Commercial & Industrial Product Guide (576047-533)

- The Red Jacket® 3/4 HP Red Armor® Submersible Turbine Pump Specifications – 60Hz (577014-468-11)

- The Red Jacket® 1.5 HP Red Armor® Submersible Turbine Pump Specifications – 60Hz (577014-468-12)

- The Red Jacket® 1.5 HP High Pressure Red Armor® Submersible Turbine Pump Specifications – 60Hz (577014-468-13)

- The Red Jacket® 2 HP Low Pressure Red Armor® Submersible Turbine Pump Specifications – 60Hz (577014-468-14)

- The Red Jacket® 2 HP Red Armor® Submersible Turbine Pump Specifications – 60Hz (577014-468-15)

- The Red Jacket® 3/4 HP Red Armor® Submersible Turbine Pump Specifications – 50Hz (577014-468-24)

- The Red Jacket® 1.5 HP Red Armor® Submersible Turbine Pump Specifications – 50Hz (577014-468-25)

- The Red Jacket® 1.5 HP High Pressure Red Armor® Submersible Turbine Pump Specifications – 50Hz (577014-468-26)

- The Red Jacket® 2 HP Red Armor® Submersible Turbine Pump Specifications – 50Hz (577014-468-27)