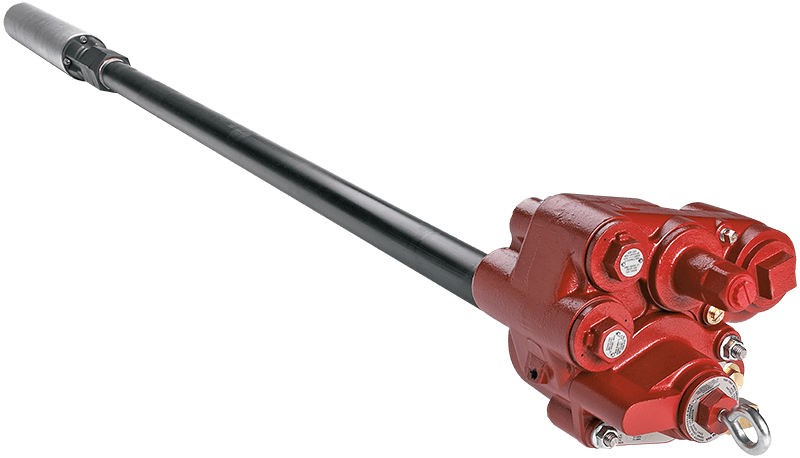

The Red Jacket® Alcohol Gas (AG) Submersible Turbine Pump

The cornerstone of your alternative fueling infrastructure, the Red Jacket AG series of submersible turbine pumps (STP) are built on the foundation of The Red Jacket model and is specially designed for resiliency in the harsh alternative fuel environment.

The Red Jacket AG STP is compatible with 100% Diesel or Gasoline, MTBE, ETBE, or TAME concentrations up to 20%, Ethanol concentrations up to 85%, Methanol concentrations up to 15%, Biodiesel concentrations up to 100%, Jet Fuel and AVGAS, Kerosene and Fuel Oil. It is UL 79A and UL 79B certified for use with renewable biofuels.

Specifications

Fuel Compatibility |

|

Motor Sizing |

|

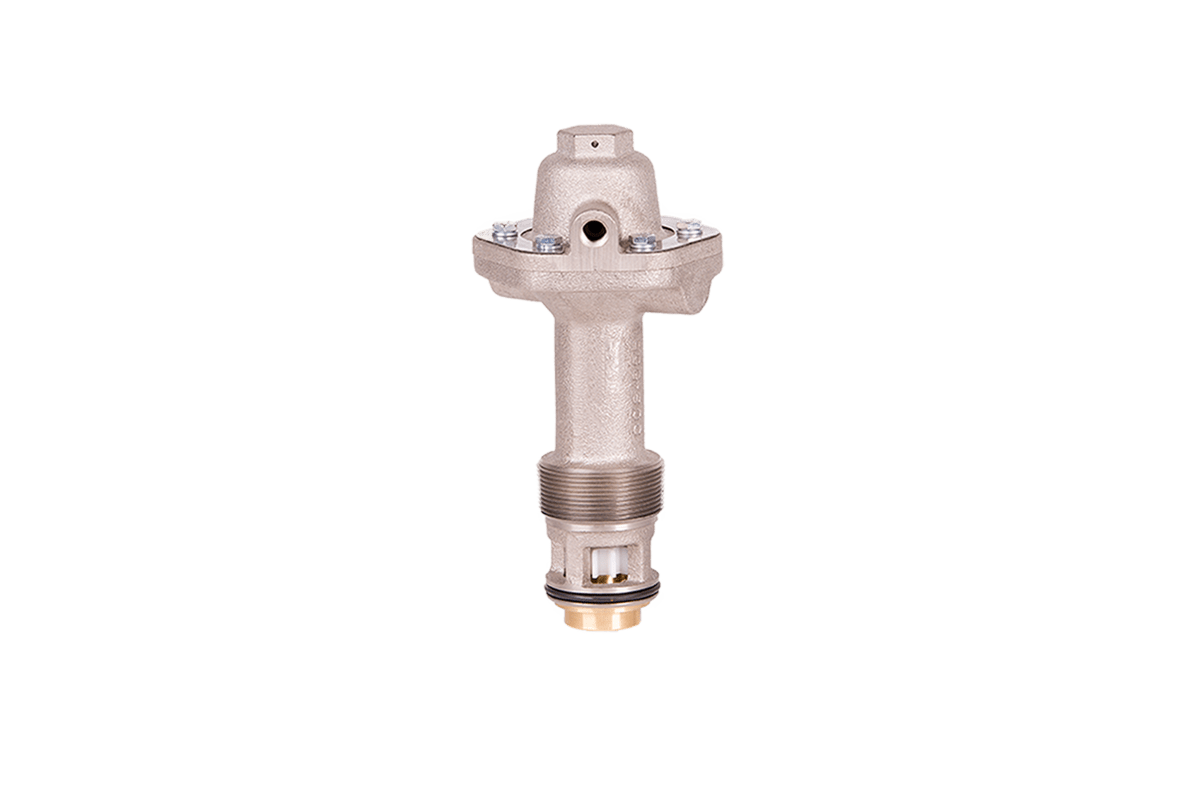

Hardware Construction | Column Pipe and Riser:

Packer Components:

|

Protective Coatings |

|

Operation Environment |

|

Installation Depth Range | Fixed Length:

Quick Set (Adjustable Length):

*Assumes 1.5 HP |

Packer Manifold Access Ports | Siphon Ports:

Line Pressure Port:

Vent Port:

|

Check Valve Compatibility |

|

Agency | UL/cUL Listings:

|

The Red Jacket Portfolio offers a variety of solutions tailored for the special requirements of resiliency in today’s renewable fuels, as well as fuels focused on improved emissions and fuel economy.

Documentation

- The Red Jacket AG Specification Sheet (576047-268)

- Red Jacket STP Fuel Compatibility (576047-305)

- Red Jacket Fixed Speed Reliability Sheet (576047-331)

- The Red Jacket STP Flow Quick Reference Guide (576047-523)

- Red Jacket Product Guide (576047-310)

- The Benefits of Owning a Red Jacket (576047-193)

- The Benefits of Servicing a Red Jacket (576047-194)

- The Red Jacket STP Installation Manual (577013-830)

- The Red Jacket STP CAD Files

- Veeder-Root Commercial & Industrial Product Guide (576047-533)

- The Red Jacket® 3/4 HP Alcohol Gas Submersible Turbine Pump Specifications – 60Hz (577014-468-6)

- The Red Jacket® 1.5 HP Alcohol Gas Submersible Turbine Pump Specifications – 60Hz (577014-468-7)

- The Red Jacket® 1.5 HP High Pressure Alcohol Gas Submersible Turbine Pump Specifications – 60Hz (577014-468-8)

- The Red Jacket® 2 HP Low Pressure Alcohol Gas Submersible Turbine Pump Specifications – 60Hz (577014-468-9)

- The Red Jacket® 2 HP Alcohol Gas Submersible Turbine Pump Specifications – 60Hz (577014-468-10)

- The Red Jacket® 3/4 HP Alcohol Gas Submersible Turbine Pump Specifications – 50Hz (577014-468-20)

- The Red Jacket® 1.5 HP Alcohol Gas Submersible Turbine Pump Specifications – 50Hz (577014-468-21)

- The Red Jacket® 1.5 HP High Pressure Alcohol Gas Submersible Turbine Pump Specifications – 50Hz (577014-468-22)

- The Red Jacket® 2 HP Alcohol Gas Submersible Turbine Pump Specifications – 50Hz (577014-468-23)