Red Jacket® Trapper Intake Screen

The Red Jacket® Trapper Intake Screen is the first line of defense against debris from microbial induced corrosion or other harmful particulate from entering the site fueling system.

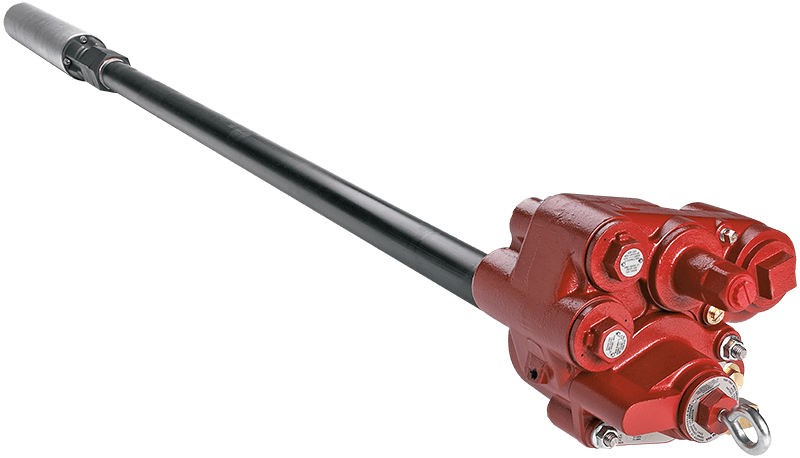

Prolong fueling equipment life and save money with the Red Jacket® Trapper Intake Screen. Unique, triangular slot design prevents accumulation and lodging of particles from underground storage tanks, maintaining peak performance of the submersible pump and keeping debris from entering the site’s fueling system and dispensers. The Red Jacket Trapper Intake Screen is the perfect accessory to the industry leading line of submersible turbine pumps (STP) provided by Red Jacket.

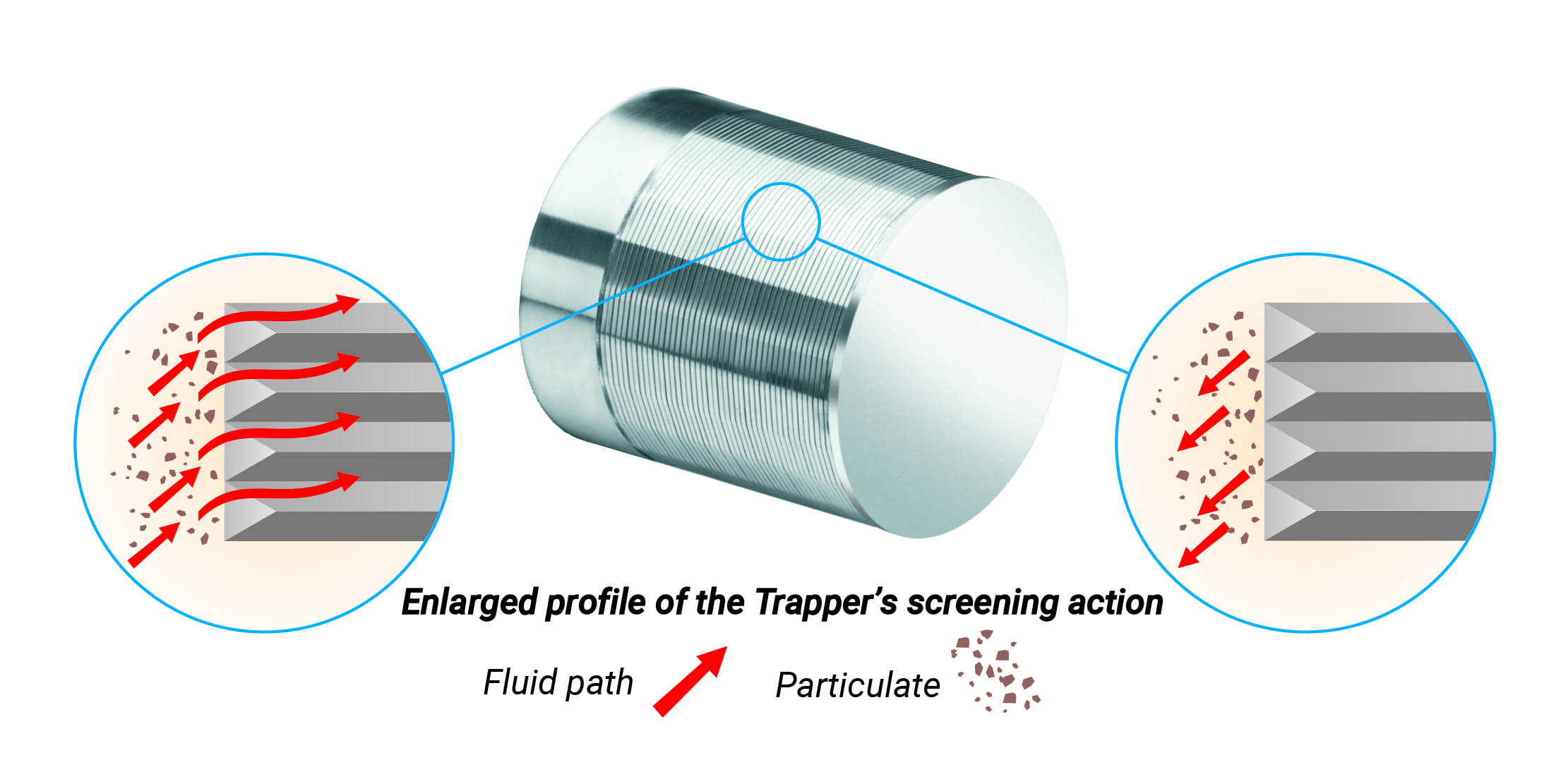

How the Red Jacket® Trapper's unique screening action works

Pump ON: The triangular design of the filter allows the free flow of fluid but blocks particulate from entering the fluid system without reducing pump performance.

Pump OFF: Self-cleaning design allows particulate to fall away from the intake when the submersible pump is turned off.

Product Form

Part Number | Description | Notes |

144-194-5 | Kit, Retrofit “Trapper” | For use with Red Jacket Submersible Turbine Pumps only |

Features and Benefits

- High-quality continuous slot design specifically engineered to fit at the end of the Red Jacket STPs. Available as a field retrofit kit for Red Jacket STPs.

- Easy, low cost retrofit kit makes the Red Jacket Trapper Intake Screen a money saver at any Red Jacket site.

- Triangular profile screen blocks tank particulates from entering the pump.

- Self-cleaning every time the submersible pump is turned off.

- Rugged 304 stainless steel construction.

- Protects STPs from rags and other larger debris.

- Reduces submersible intake filter changes to as low as once per year per line, saving on labor and filter costs by preventing tank particulates from entering the fluid system.

- Decreases environmental liability by reducing the potential for filter seal leaks due to frequent filter changes.

- Reduces the amount of hazardous waste generated by used filters.

- Non-clog design does not require scheduled maintenance.

- Prolongs dispenser life.