Increased Risk in Diesel USTs

The EPA phased-in more stringent regulations to lower the amount of sulfur in diesel fuel in 2006, which led to ultra-low sulfur diesel becoming the standard formulation found in retail stations. Reducing the amount of sulfur changed the environment in which diesel fuel is stored, allowing for an increase in Microbiologically Influenced Corrosion (MIC) of in-tank fueling equipment.

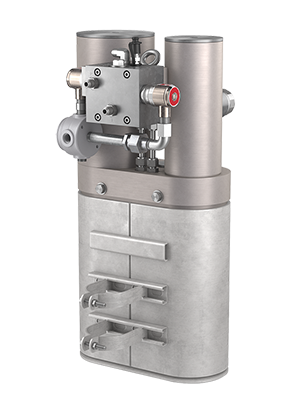

The HydrX™ Fuel Conditioning System combats in-tank corrosion and maintains optimum tank health for diesel underground storage tanks. It removes water from the tank and filters fuel continuously, eliminating corrosion and maintains diesel fuel quality.

Handling Emerging Fuels

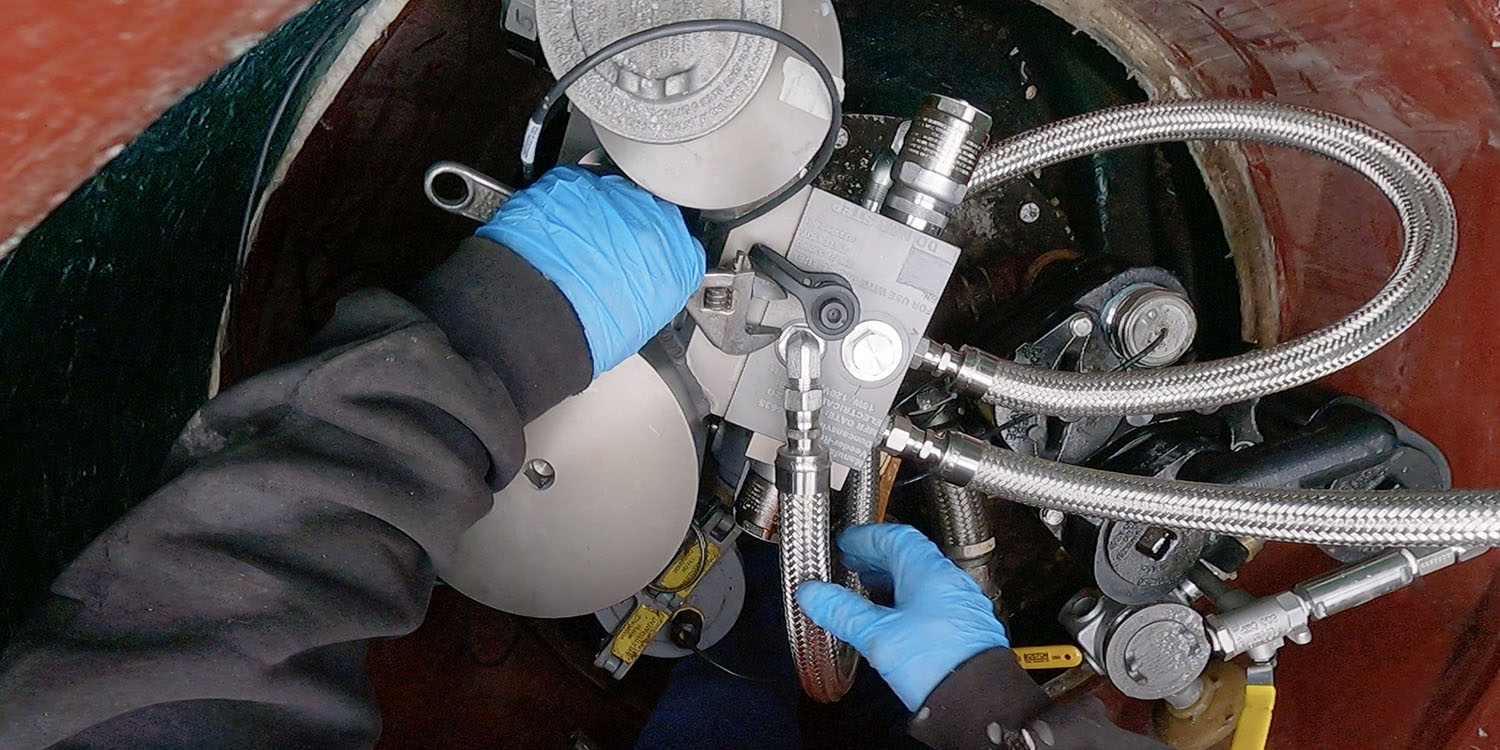

New fuel formulations also affect the submersible turbine pumps (STPs) that are used to pump fuel up from the underground storage tanks and through the fuel lines. The submersible turbine pumps consist of a motor that is submerged in the fuel connected by a column pipe to the packer-manifold, which is in the sump space. The submersible turbine pump is subjected to corrosive conditions on the fuel path inside the pump, and on exposed surfaces in the tank and in the sump.

The Red Jacket® Alcohol Gas STP and The Red Armor® STP are both constructed with stainless steel on all parts exposed to the fuel path. This allows these STPs to handle biodiesel concentrations up to 100% and ethanol concentrations up to 90%. The Red Armor STP has an additional 30% increase in stainless steel hardware from The Red Jacket AG STP and a special coating that makes it ideal for withstanding corrosion in the tank and sump.

The Red Jacket® Alcohol Gas STP and The Red Armor® STP are both constructed with stainless steel on all parts exposed to the fuel path. This allows these STPs to handle biodiesel concentrations up to 100% and ethanol concentrations up to 90%. The Red Armor STP has an additional 30% increase in stainless steel hardware from The Red Jacket AG STP and a special coating that makes it ideal for withstanding corrosion in the tank and sump.

Additional corrosion protection can be added to any submersible turbine pump by including the Red Jacket Trapper Intake Screen or Red Jacket Stainless Steel Riser Pipes. The Red Jacket Trapper Intake Screen protects your fueling equipment from particulate that has resulted from microbial growth in your underground storage tank. Red Jacket Stainless Steel Riser Pipes stand up to corrosive environments and maintain their integrity against standing water in sump spaces. Because they won’t degrade or corrode, the Stainless Steel Riser Pipes keep water from seeping from the sump to the UST and maintain serviceability.

Maintaining Sump Spaces

With many sump spaces frequently taking on water, there is an increased chance that the water and vapors from the emerging fuels will create an environment where corrosion can thrive. This increase in corrosion on fueling equipment surfaces reduces the lifetime of the equipment and can cause premature breakdown.

The Red Jacket® Sump-Dri™ Desiccant System is specifically formulated to reduce the relative humidity in a STP sump and neutralize corrosive acetic vapors. The absorbed moisture and neutralized acetic acid vapors create a brine solution, which is collected and trapped in the reservoir to limit re-evaporation. Removing the moisture helps eliminate corrosion, which keeps the sump in better condition, enabling easier access for service and ensuring longer life of parts contained in the sump.

Need help selecting the right products? Consider these key questions.

Read all our Combat Corrosion Articles

Water is integral to corrosive environments and a serious threat to diesel storage tanks and fuel equipment health. Learn more about the cause and impact of corrosion, and steps you can take to mitigate it.

Read More

* Wardzińska, Dorota, and Monika Ziółkowska. "Corrosiveness of Fuels During Storage Processes". Reviewed: October 30th 2014. Published: February 4th 2015. Accessed: June 15 2021. https://www.intechopen.com/books/storage-stability-of-fuels/corrosiveness-of-fuels-during-storage-processes