A FAMILIAR PROBLEM – WATER

The systemic issues Cumberland Farms experienced at their initial HydrX installation site are not unique to the industry. When fuel, microbes, and water combine, the result is a corrosive environment.

Advancements in diesel fuel, particularly Ultra-Low Sulfur Diesel and Biodiesel, create an environment where microbial growth can flourish. Water entry into the diesel storage environment is inherent in the process as it enters through leaky seals, flooded spill buckets, atmospheric moisture, and deliveries. Water entrained in a warmer fuel load may fall out of suspension when it enters the tank and cools down. It is the fuel-water interface that is central to microbial growth because the water provides a suitable environment for microbes to thrive within the underground storage tank.

For Cumberland Farms, that meant frequently troubleshooting emergency line leak test failures by replacing check valves, replacing dispenser filters due to slow flow, and even performing full STP replacement within 1.5 - 2 years from the date of installation.

|

“The HydrX Fuel Conditioning System’s ability to remove standing water from the lowest point of a fuel tank coupled with our unique fuel filtering technology helps site owners avoid costly equipment failures and downtime caused by excessive corrosion.”

- Stephen Coppola, Global Product Manager, Veeder-Root

ASSESSING THE SITUATION

Jim Scholes, Senior Project Manager of Construction, and his team at Cumberland Farms, knew that HydrX could help optimize the health of their diesel tanks by reducing water contamination and the Microbiologically Influenced Corrosion (MIC) that comes with it.

To fix these problems at the source, the Veeder-Root team began with a preliminary site inspection and evaluation. This included obtaining baseline fuel samples from the tank and nozzle, analyzing samples for baseline acidity and moisture content, and taking site measurements for the HydrX Fuel Conditioning System.

Site measurements were critical to understand how the tank was tilting. The Water Intake Device (WID) of HydrX is designed to extract water from the lowest point in the tank and is customized to work with the unique conditions at any site.

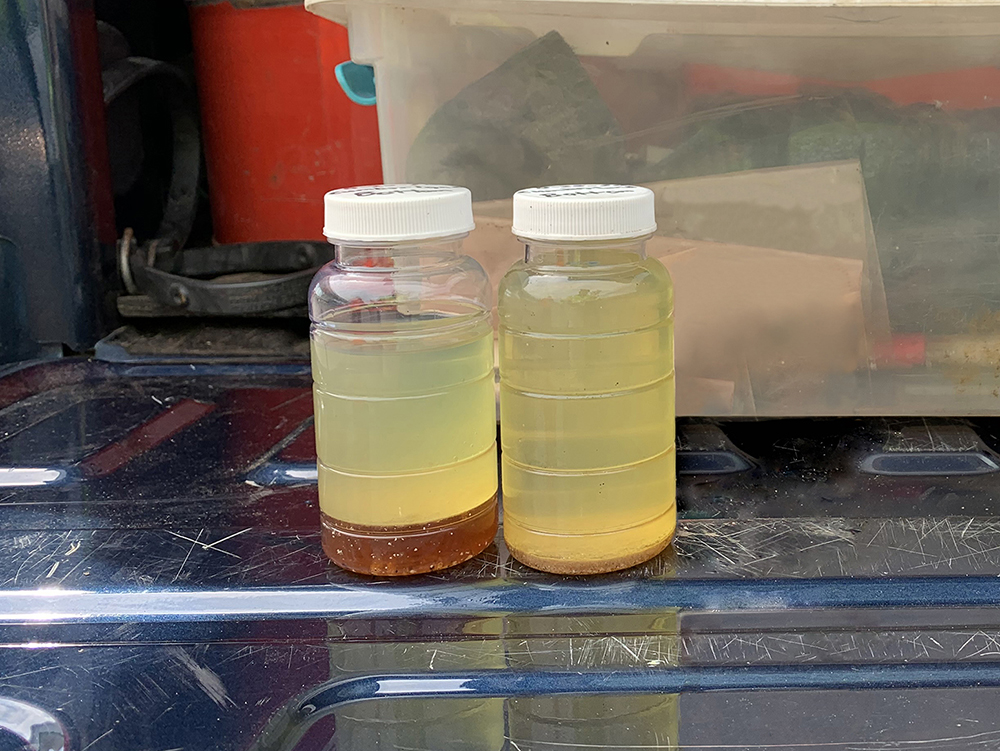

The fuel samples from the tank showed the expected symptoms for any site being affected by long-term water issues. There was visible corrosion on components exposed to the storage environment, and evidence of water and microbial growth in fuel samples obtained from the tank bottom.

PUTTING THE PLAN INTO ACTION

Solving the water issues discovered during the site evaluation began with a tank cleaning prior to the installation of HydrX, in order to reset the tank to a healthy baseline and to ensure optimum performance of the system. A tank that is clean to start results in a lower cost of ownership due to less frequent filter replacements, component services, and/or fueling system maintenance.

Solving the water issues discovered during the site evaluation began with a tank cleaning prior to the installation of HydrX, in order to reset the tank to a healthy baseline and to ensure optimum performance of the system. A tank that is clean to start results in a lower cost of ownership due to less frequent filter replacements, component services, and/or fueling system maintenance.

Next, the HydrX Fuel Conditioning System was installed to provide continuous water removal within the diesel underground storage tank. This particular tank was tilted away from the STP sump, which put the stagnant water 22 feet away from the point of entry into the tank. The WID was sized to reach this lowest point of the tank, ensuring the stagnant water would be eliminated.

I definitely want to use HydrX going forward, I think it has value in the new construction environment. Even with a new site, new tanks…we’re still seeing issues with ULSD. In my opinion, we should be installing this in new construction rather than just use it in a retrofit application at the trouble sites.

– Jim Scholes, Senior Project Manager of Construction, Cumberland Farms, EG Group

HYDRX WATER REMOVAL

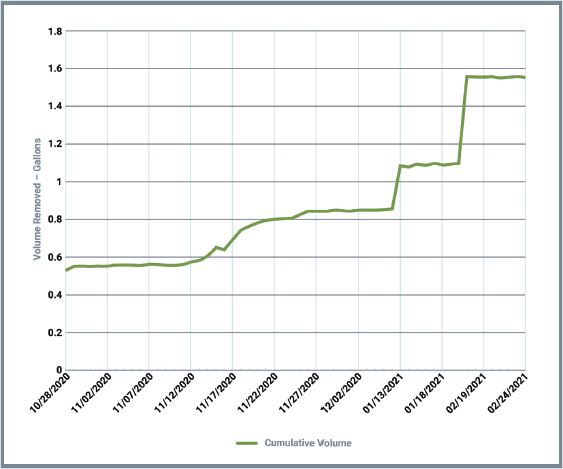

Since the installation of the HydrX Fuel Conditioning System, the results have spoken for themselves. Within the first 24 hours, HydrX removed just over a half-gallon of water that had entered the tank since the tank was cleaned. Over the next 30 days, the extracted water volume continued to increase incrementally to nearly 1 gallon. The quality of the tank bottom fuel samples was visually evident. The samples were clean and bright with no signs of water present in the fuel.

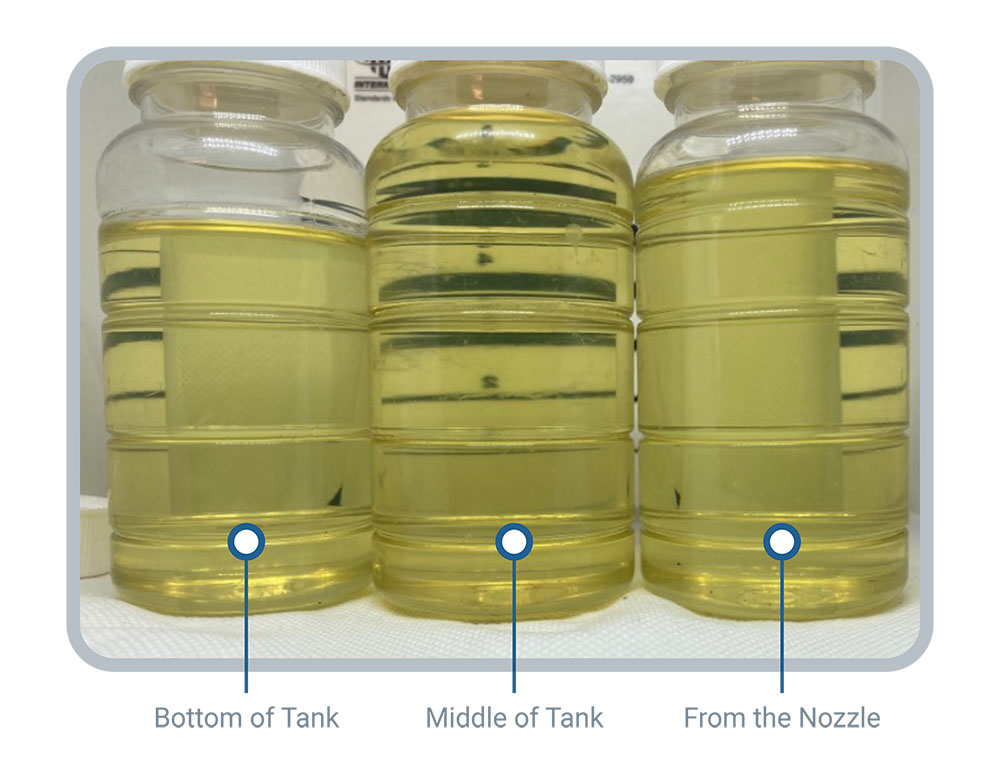

After just 90 days, extracted water volume nearly doubled, fuel quality within the tank was restored, and fuel samples from the bottom of the tank were indistinguishable from those at the nozzle, indicating that the conditions in the tank have stabilized and microbial growth is being mitigated.

SEEING THE RESULTS

Looking at key leading indicators to corrosion, water content (PPM) in the samples from the bottom of the tank have shown a downward (favorable) trend. After 120 days, the values have stabilized at a low level and are now equivalent to the samples from the nozzle. The pH of the samples from the bottom of the tank started in a corrosive range. Since the HydrX installation, pH has also continued to improve, approaching 6.5 which is on the very edge of a passive oxide surface with no ongoing corrosion.

PUTTING A PAUSE ON CONDITIONING

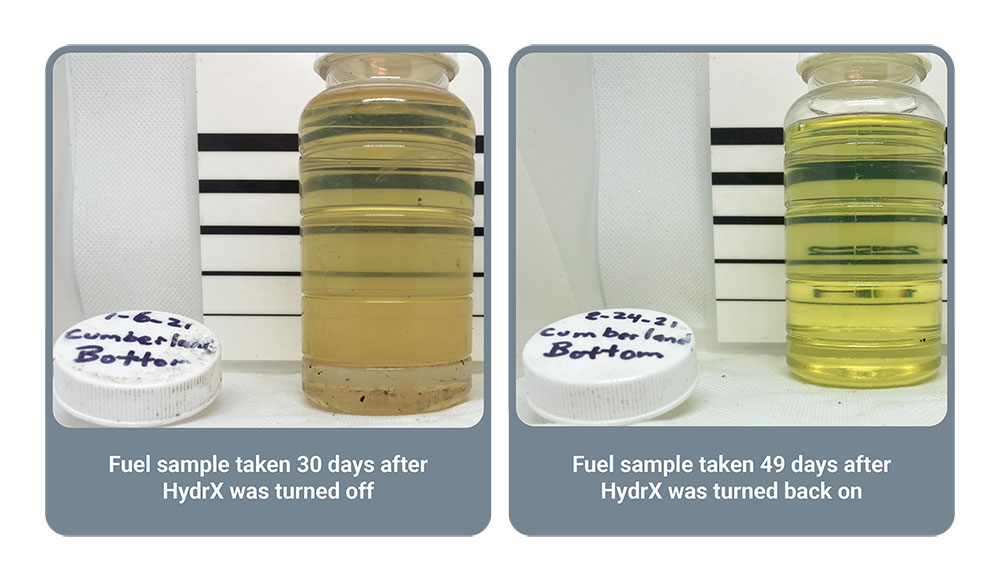

To further prove system efficacy, HydrX was turned off for a period of time. It did not take long for there to be visible signs that the quality of the fuel was degrading and the eventual corrosive conditions would return.

After 30 days, there was evidence of standing water and dark particulate in the fuel. The fuel itself was losing clarity and turning to a dark amber color. When HydrX was restarted, there were immediate signs that the system was correcting the conditions inside the tank – standing water was eliminated and the clarity of the fuel returned.

THE PROOF IS IN THE PETROL

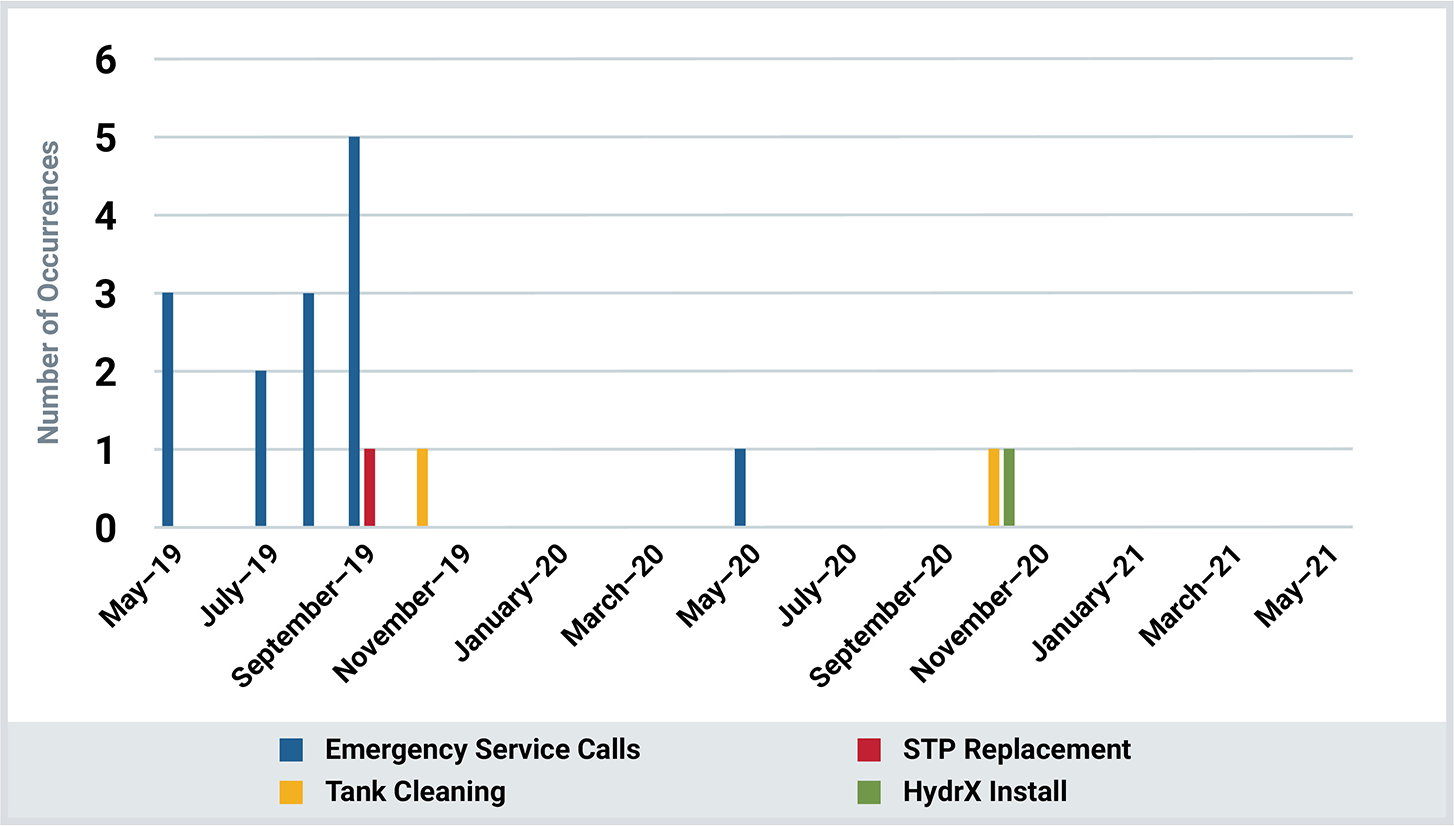

From the samples pulled at 120 days after installation, the evidence is clear that the system is working. Prior to the installation of HydrX, emergency service calls to correct corrosion related issues were frequent and started to show up not long after tank cleaning.

These issues consumed resources and caused downtime at the site. Post installation, corrosion-related service calls were eliminated and there are no leading indicators that they will be returning anytime soon. HydrX is protecting the conditions inside the tank from water and microbial growth.

DIESEL TANK MAINTENANCE

It is working so well, in fact, that after just a few months with HydrX in place, Cumberland Farms is planning a roll-out of the system at their new construction properties to prevent issues before they happen, not only as a reactive measure at existing sites.

"The return on investment? It pays for itself."

- Chris Desaulniers, FSS Project Manager, Cumberland Farms, EG Group

TALK TO AN EXPERT

Other systems work to remove water from only the immediate area around the submersible turbine pump — HydrX is different.

HydrX uses suction tubes that extend along the Water Intake Device, removing water all along the tank bottom. Its unique vacuum mechanism is powered by the STP, continuously circulating tank bottom fluids through a filter and water containment vessel in the sump.