Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

There are more than 568,000 underground storage tanks (USTs) at 202,000 sites across the United States that are regulated by the Environmental Protection Agency’s (EPA) technical regulations. Of these, nearly 27% are not in significant operational compliance with either release prevention or leak detection requirements.

The costs of being out of compliance with the EPA’s UST regulations can be great, in the form of expensive fines, costly, cleanup and irreversible environmental damage. However, with effective leak detection measures in place in all of the regulated areas at your fueling site, you can detect any leaks quickly and minimize cost and damage.

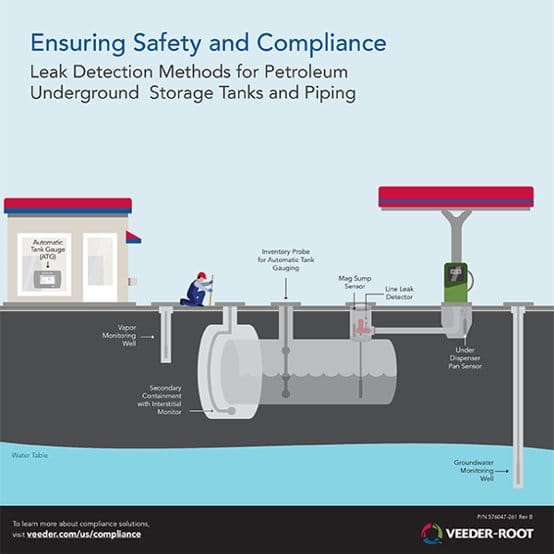

The products below represent the recommended leak detection methods for identifying and preventing potential leaks at your fueling station, including Automatic Tank Gauging (ATG) consoles and secondary containment with interstitial monitoring, as well as vapor and groundwater monitoring.

Automatic Tank Gauging- Automatic Tank Gauges, or ATGs, replace the need for manually sticking tanks to perform inventory measurement. “When installed and operated according to the manufacturer's specifications, [ATGS] meet the federal leak detection requirements for tanks.”1 In an ATG, the product level and temperature are measured continuously by an inventory probe in your tank and are recorded automatically by a computer. The ATG interface typically sits in the back room of the station and sounds an alarm when it detects a potential leak, fuel overfill, equipment failure, or other potential site issue. Owners or operators of multiple fueling sites can access ATG information remotely to centralize management of the alarms.

Secondary Containment with Interstitial Monitor- Secondary containment of a UST involves the use of a barrier, outer wall, or liner around the UST. This way, any product that may leak from the UST is collected in the interstitial containment area and detected by an interstitial sensor, rather than leaked into the environment unnoticed.

Vapor Monitoring- Vapor monitoring uses the installation of monitoring wells to measure either product fumes in the soil around the UST or special tracer chemicals added to the UST which escape in order to check for a leak.1

Mag Sump Sensor & Under Dispenser Pan Sensor- These sensors are positioned at the bottom of containment sumps such as the submersible turbine pump sump or the under dispenser pan and can detect both the presence and amount of liquid in the sump. Discriminating sump monitoring sensors can tell the difference between the presence of water and the presence of a fuel product, which can potentially eliminate the need for a costly service call.

Line Leak Detector- The EPA requires that all pressurized piping automatic line leak detection.2 Automatic flow restrictors and shut-off functions monitor the pressure within the line and perform flow restricting or flow stopping actions when line pressure drops below a certain level, suggesting a potential leak.

Groundwater Monitoring- Groundwater monitoring involves the use of permanent monitoring wells placed close to the UST to detect the presence of liquid product floating on the groundwater (EPA, 2005). These wells can be checked periodically by hand or continuously with permanently installed equipment such as groundwater sensors, but cannot be used at sites where groundwater is more than 20 feet below the surface.

For more detailed information about UST regulations, visit the EPA’s UST Release Detection Guide, or visit our solution page METHODS OF LEAK DETECTION FOR UNDERGROUND STORAGE TANKS.

1 United States Environmental Protection Agency. (May 2016). Straight Talk On Tanks - Leak Detection Methods For Petroleum Underground Storage Tanks And Piping. https://www.epa.gov/sites/production/files/2016-05/documents/stot_5-2-16_final_508.pdf

2 “Release Detection for Underground Storage Tanks (USTs).” United States Environmental Protection Agency. (2016). https://www.epa.gov/ust/release-detection-underground-storage-tanks-usts#pressurized