Installation Review

This example shows a clean installation

![]() All wires – low and high voltage – exit the console and immediately enter a rigid conduit. Unlike the image on the next page, the rigid conduit reduces or prevents opportunities for non-intrinsically safe wiring from being placed next to or in the same conduit as Veeder-Root’s probe and sensor wiring.

All wires – low and high voltage – exit the console and immediately enter a rigid conduit. Unlike the image on the next page, the rigid conduit reduces or prevents opportunities for non-intrinsically safe wiring from being placed next to or in the same conduit as Veeder-Root’s probe and sensor wiring.![]() In addition, the console has not been altered in any way; unused knock-outs have been left in place and the divider walls have not been removed (each module is physically separated with a metal plate).

In addition, the console has not been altered in any way; unused knock-outs have been left in place and the divider walls have not been removed (each module is physically separated with a metal plate).![]() Although not required, the high and low voltage wires are pulled in opposite directions. This reduces the chances of these wires being placed side by side inside a wiring trough.

Although not required, the high and low voltage wires are pulled in opposite directions. This reduces the chances of these wires being placed side by side inside a wiring trough.

The example on the right shows an incorrect installation.

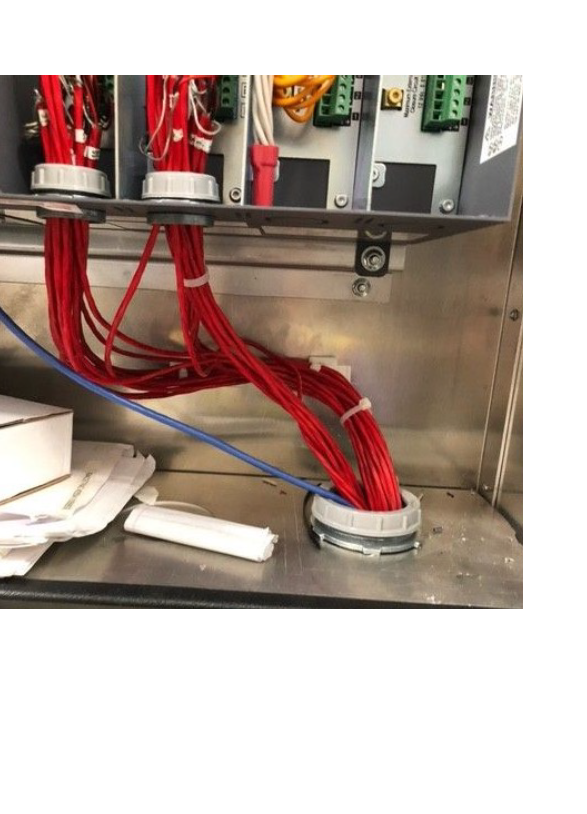

![]() A non-intrinsically safe wire (blue) is entering the same space and conduit where the Veeder-Root’s probe and sensor wires (red) have been installed.

A non-intrinsically safe wire (blue) is entering the same space and conduit where the Veeder-Root’s probe and sensor wires (red) have been installed.

![]() This installation did not use any conduits. If the intrinsically safe wires (red) had been previously installed in their own rigid conduits, these wires would have a physical separation from the blue wire.

This installation did not use any conduits. If the intrinsically safe wires (red) had been previously installed in their own rigid conduits, these wires would have a physical separation from the blue wire.

![]() Even if a space inside the cabinet will only contain intrinsically safe wiring, it is still a requirement to run the wires inside rigid conduit. This will prevent intrinsic safety violations if other wires are run through this space after the cabinet is installed.

Even if a space inside the cabinet will only contain intrinsically safe wiring, it is still a requirement to run the wires inside rigid conduit. This will prevent intrinsic safety violations if other wires are run through this space after the cabinet is installed.

Note: Local regulations might require AC and DC voltages to be separated. Comply with local wiring codes.

Further Information

- Contact Veeder-Root Technical Support at +1.800.323.1799 for additional help or questions.

- Learn more about intrinsic safety and wiring requirements in the TLS-450PLUS Site Prep and Installation Manual (577014-073) and by viewing the UL/cUL Control Drawing - TLS-450/8600 Consoles (331940-008).