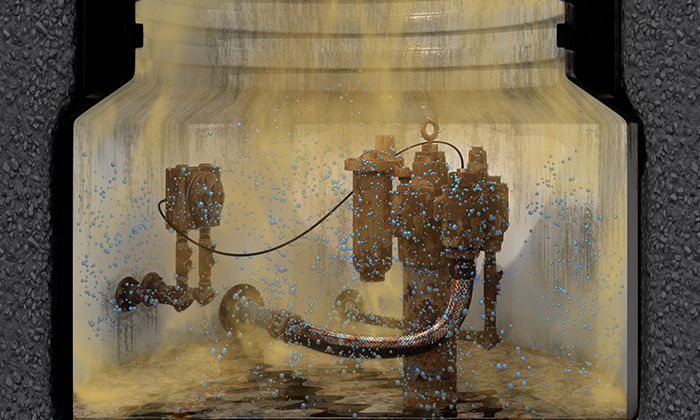

WHY IS CORROSION OF IN-SUMP EQUIPMENT AN ISSUE?

Corrosion of equipment in sumps causes deterioration and shortens its useful life span. As corrosion advances it has the potential to affect the integrity of piping and electrical systems, and the serviceability of submersible turbine pump (STP) equipment.

Corrosive conditions are caused when three common components are present:

- Ethanol Vapors

- Water

- Bacteria

Water provides an environment where bacteria can degrade the ethanol vapors to create acetic acid. Acetic acid is then the catalyst for the process of corrosion to begin.

WHAT ARE THE FIRST STEPS TO LIMITING CORROSION?

The corrosive process needs ethanol vapors, water, and bacteria to create acetic acid. To reduce the likelihood of corrosion in a sump, eliminate the presence of any one of these components.

Limiting the amount of ethanol vapor in sump spaces is done by eliminating any possible vapor paths in sump equipment. Use secondary containment sensors to identify liquid and remove standing water, the goal for limiting corrosion should always be to maintain a dry sump.

First steps include:

- ENSURE FITTINGS are fuel tight.

- CHECK VENT TUBES AND FITTINGS where vapors may have a path through from tank head space.

- CHECK cord grips, manway caps, gaskets and electrical conduit for potential water ingress.

- ENSURE THAT RISER PIPES AND FITTINGS are installed appropriately.

LIMITING IN-SUMP CORROSION

To combat corrosion it’s important to understand the conditions in your sump.

Key Questions to Consider:

If you anticipate standing water:

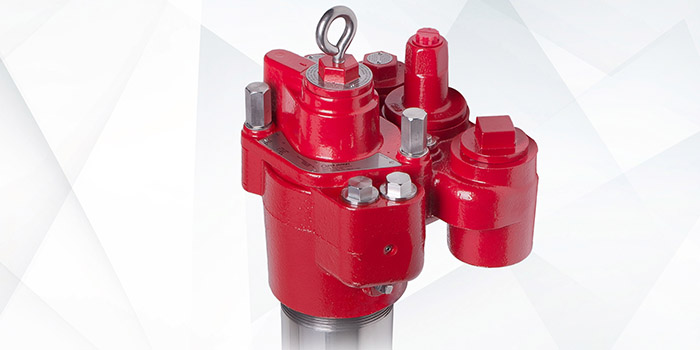

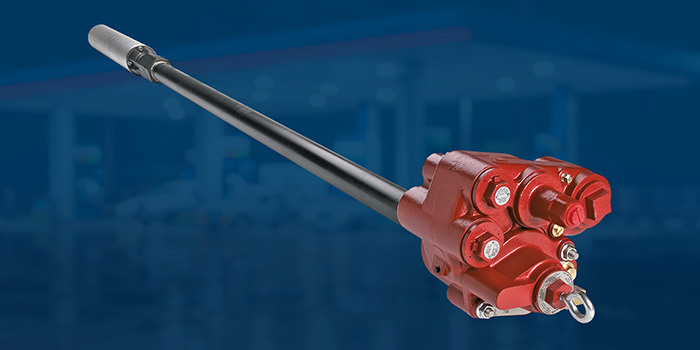

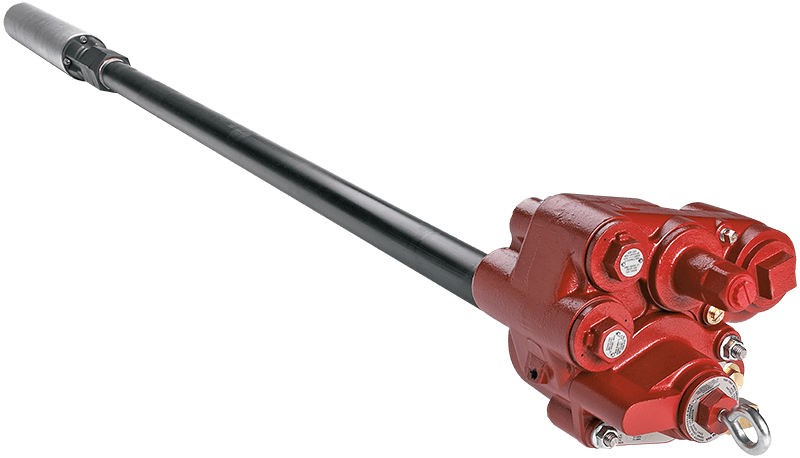

In cases where water is present and the sump space is not tight, there is limited ability to control the conditions to reduce the likelihood of corrosion. For this purpose, the Red Jacket® Red Armor® STP includes a stainless steel riser, stainless hardware on the Packer Manifold, and a specialty protective coating to stand up to additional moisture in the sump. If using an existing The Red Jacket STP consider installing a stainless steel riser to protect against water getting into the tank from corrosion of the riser threads.

Learn more about Stainless Steel Riser PipesIf you are using ultra-low sulfur diesel and are concerned about corrosion:

The use of ultra-low sulfur diesel creates an environment in the sump that is prone to causing equipment corrosion. The stainless steel construction of all exposed surfaces ensures the Red Jacket Red Armor STP will maintain its integrity and stand up to corrosion in the sump and in the tank. This includes stainless steel column piping and specialty coating on UMP surfaces for increased protection of materials in the storage tank.

Learn more about The Red Armor STPIf you are dispensing high-ethanol blends:

Operating with high-ethanol blends increases the amount of ethanol vapor in the sump space which can accelerate corrosion. The Red Jacket Red Armor STP stands up to the corrosive environment.

If you are operating E85 or B-20 – B100:

The Red Jacket Alcohol Gas (AG) Submersible Turbine Pump models are built with materials compatible with Ethanol and Biodiesel blended fuels, and have received UL79A & UL79B certifications for renewable biofuels.

Learn more about The Red Jacket Alcohol Gas STPIf you are operating in E10 – E15:

The Red Jacket STP is compatible with fuel blends that feature lower concentrations of ethanol.

If you are operating in Clear Gas (no ethanol) or 100% Diesel:

In sumps operating in Clear Gas or 100% Diesel and free from standing water, the likelihood of corrosion is lower and you should use The Red Jacket STP.

Learn more about The Red Jacket STP