Troubleshooting

During the start of a periodic test, when the pump turns on, a pressure spike is trapped in the line. During this spike, two pressure readings (P1 and P2) are recorded. A leak rate is calculated based on these two pressure readings and the duration of the spike. This process is repeated a second time and is then followed by the mid-range test. The mid-range test is a pump off test.

If the mid-range test fails, the periodic test will also fail. A passing mid-range test does not guarantee a passing periodic test.

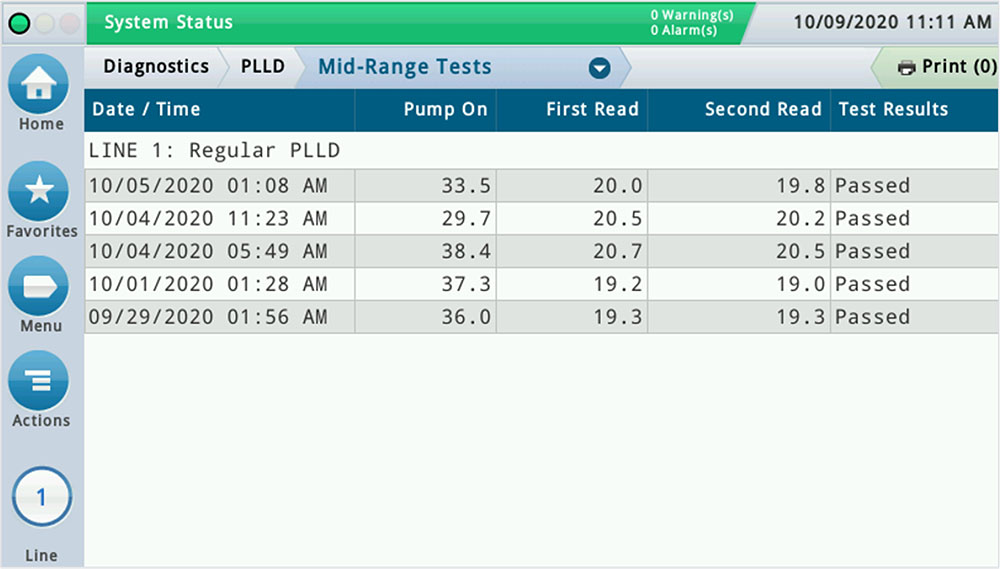

Mid-range tests

The mid-range tests TLS-450PLUS screen or TLS-350 printout shows the five most recent passes and five most recent fails per line.

TLS-450PLUS

Menu > Diagnostics > PLLD > Mid-Range Tests

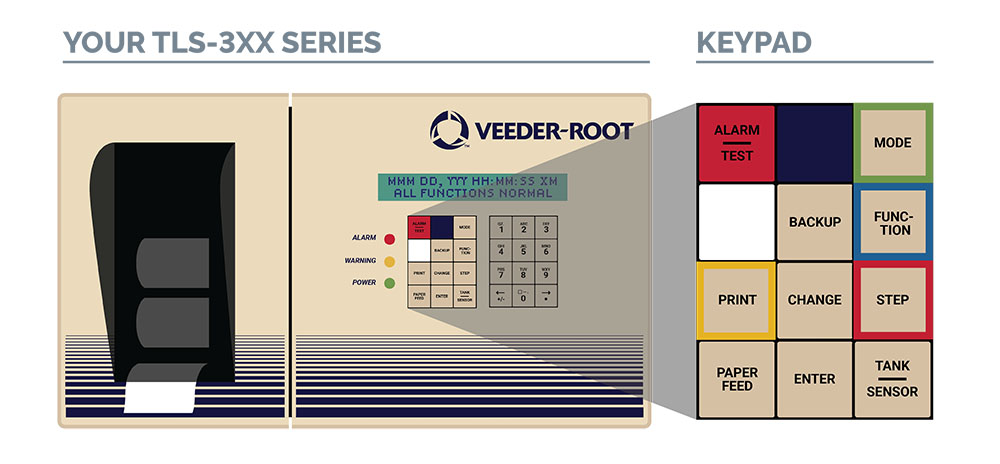

TLS-350

1. Press MODE for DIAG MODE

2. FUNCTION to PRESSURE LINE LEAK DIAG

3. STEP to MID DIAG

4. Press PRINT

Troubleshooting Process

Note: For a more detailed description of the mid-range test pressure readings and possible causes, refer to the Technical Support Notification – PLLD – Gross Line Failure (576047-364).

- Check the ratio and test duration (see below).

- Close the shear valves under all dispensers and check for visible leaks. This will isolate the dispensers from the line and STP.

- Run a manual periodic test – with the dispenser shear valves closed, a failing periodic test indicates a line or STP issue. A passing test could indicate a dispenser issue.

Note: If the shear valves are closed and the periodic test fails two times, consider a third-party test.

Ratio and Test Duration

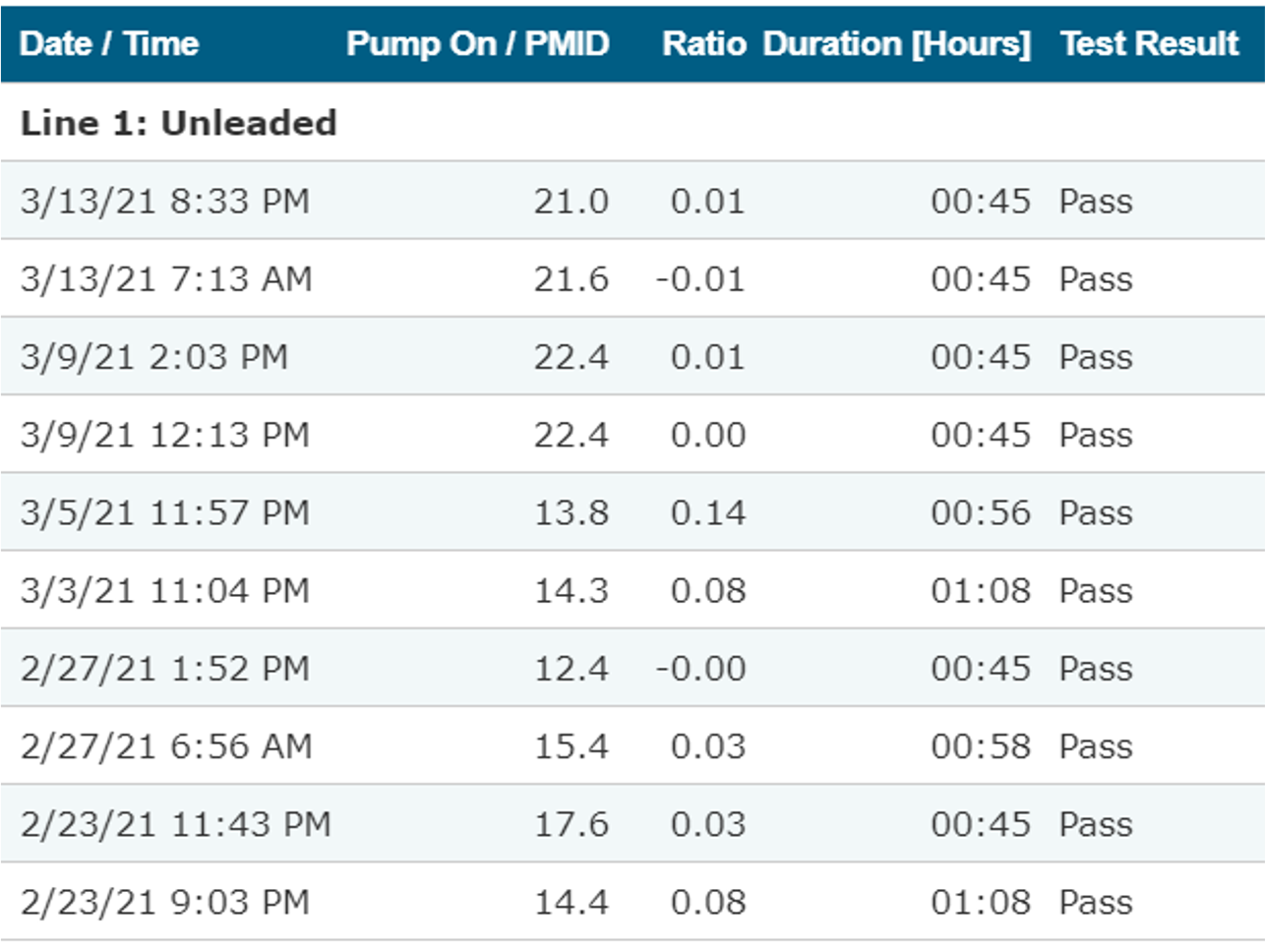

Check the PLLD diagnostics for the 0.2 GPH tests for more information.

TLS-450PLUS

Menu > Diagnostics > PLLD > 0.2 GPH TESTS

TLS-350

1. Press MODE for DIAG MODE

2. FUNCTION to PRESSURE LINE LEAK DIAG

3. STEP to 0.2 DIAG

4. Press PRINT

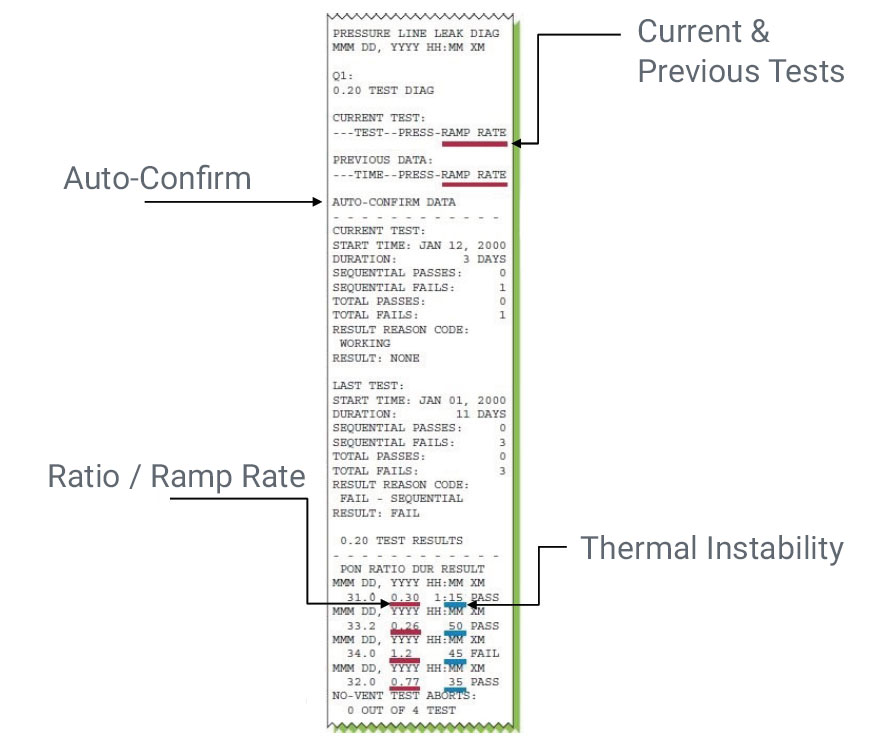

0.2 GPH Test Information

Current & Previous Tests

Rates must be close for the thermal stability to be declared.

Auto-Confirm

If auto-confirm is enabled, use the auto-confirm data to identify whether or not the failure is consistent.

Note: A manual test bypasses the auto-confirm filter.

When auto-confirm is enabled, two periodic line tests must fail before the alarm is displayed. To clear the alarm, two periodic tests must pass.

Ratio / Ramp Rate

Note: The ratio doesn’t show where the failure is taking place. It only shows how close the test is to passing.

Pon Ratio = Ramp Rate/Fail threshold

>1.0 = Fail and <1.0 = Pass

The ratio indicates how close the test is to the failure threshold. Large variations in ratio indicate an intermittent problem, such as a valve not always seating properly.

Thermal Instability

Long durations indicate there was a lot of thermal activity during the test.

Note: Too much thermal activity can prevent a test from completing.

Further Information

- Contact Veeder-Root Technical Support at 1-800-323-1799 for additional help or questions.

- Learn more about Pressurized Line Leak Detection

- Technical Support Notification - PLLD – Periodic Line Failure (576047-380)