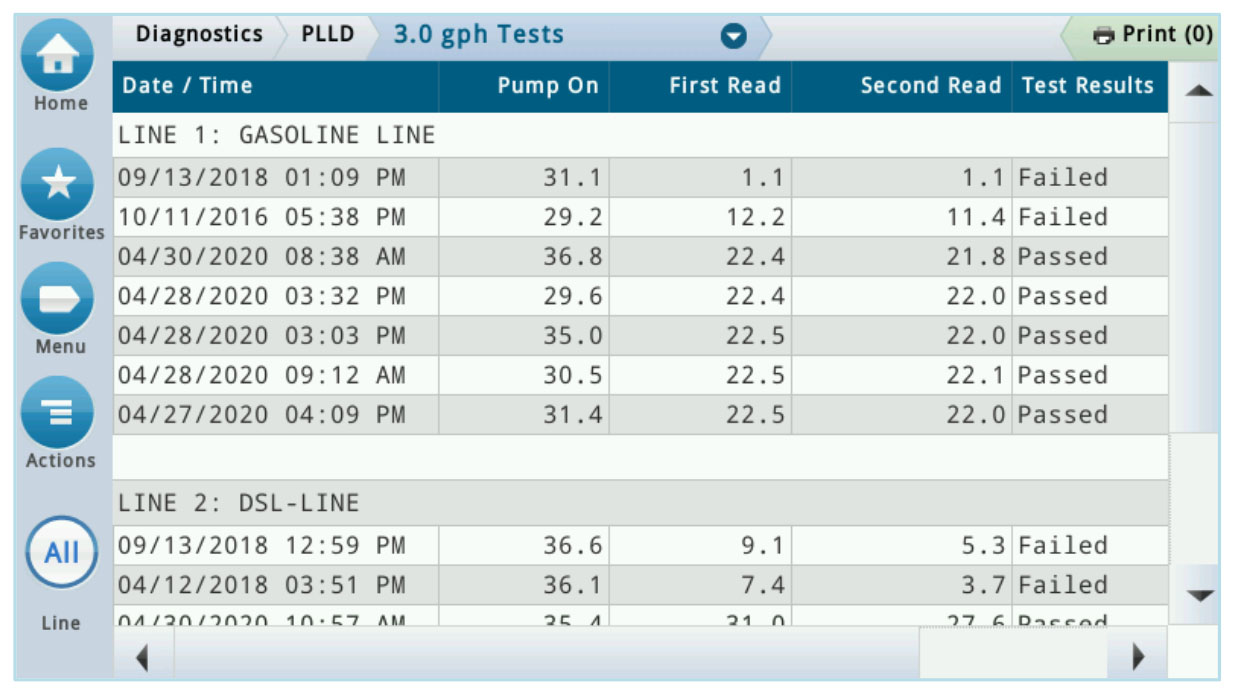

Accessing PLLD Records

- TLS-450PLUS

Menu > Diagnostics > PLLD > 3.0 gph Tests

This screen displays the five most recent passes and five most recent fails per line.

- TLS-350

- Press MODE for DIAG MODE

- FUNCTION to PRESSURE LINE LEAK DIAG

- STEP to 3.0 DIAG

- Press PRINT

The printout will display the five most recent passes and fails for the line selected.

- Run a manual gross line test.

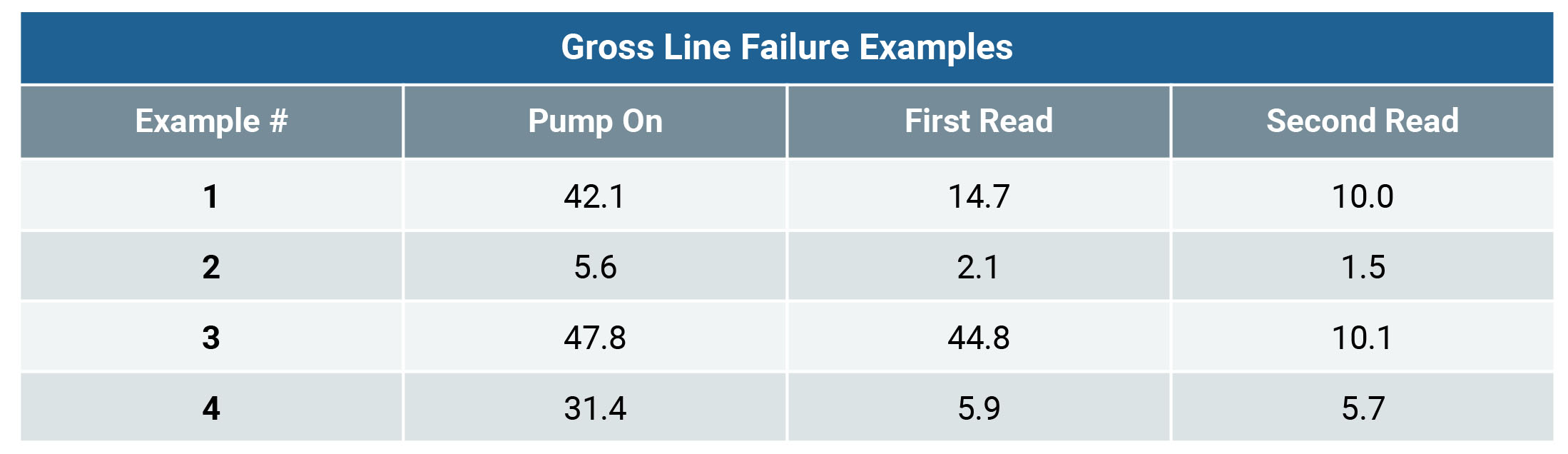

Troubleshooting Examples:

Possible Causes for Each Example:

Example 1

|

Example 2

|

Example 3

|

Example 4

|

Further Information

- Contact Veeder-Root Technical Support at 1-800-323-1799 for additional help or questions.

- Learn more about Pressurized Line Leak Detection

- Technical Support Notification - PLLD - Gross Line Failure (576047-364)