Troubleshooting: TLS4 Series

Review the CSLD Diagnostics Report

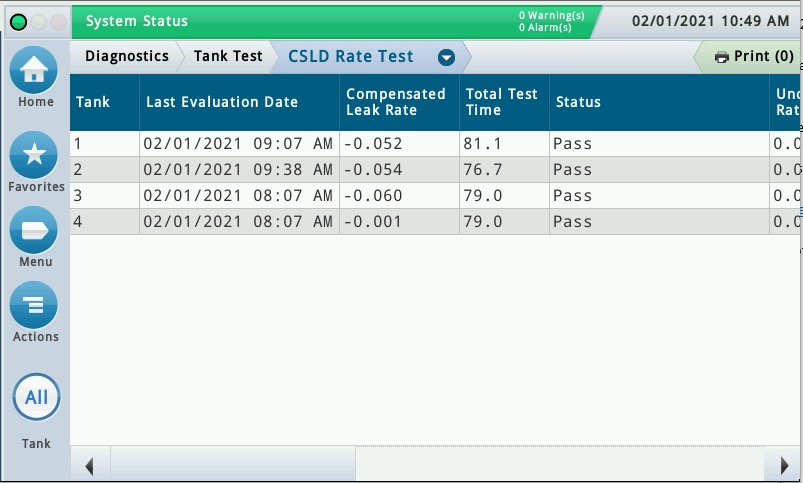

Menu > Diagnostics > Tank Test > CSLD Rate Test

The CSLD Diagnostic Report for each tank will be displayed on this screen. (Scroll to the right for additional test results.)

Troubleshooting: TLS-350

Review the CSLD Diagnostics Report

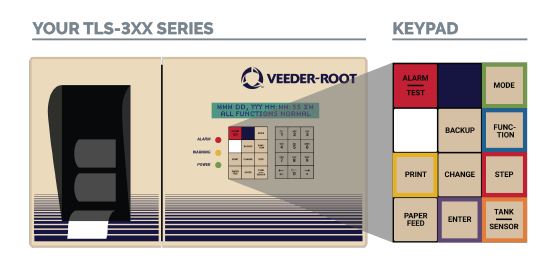

1. Press MODE for DIAG MODE

2. FUNCTION to CSLD DIAGNOSTICS

3. STEP to CSLD DIAGNOSTICS REPORT

4. Press ENTER

5. If needed, press the TANK/SENSOR button to select the correct tank

6. Press PRINT to easily review the results

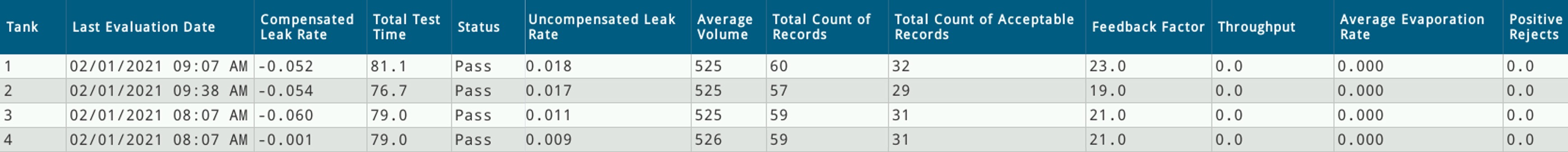

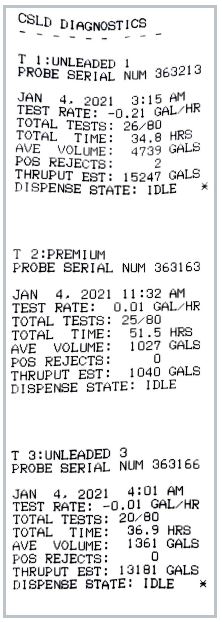

CSLD Diagnostics

- Test Rate:

The CSLD leak rate threshold is -0.17 gph for a stand-alone tank, -0.16 gph for a siphoned tank. - Total Tests:

Total number of accepted tests listed in the rate table. Tests are rejected due to temperature change, deliveries, or the testing duration is too short. - Total Time:

Sum of all the accepted tests. CSLD requires a minimum of 6 hours to produce a valid result. - Average Volume:

Tank’s average fuel volume during testing times. CSLD can only detect leaks in the part of the tank that has fuel in it. A higher average volume indicates a more comprehensive test. - POS (Positive) Rejects:

The number of tests rejected due to a leak rate of +0.4 gph or higher, out of the last 20 completed tests. - Throughput:

Estimated monthly throughput (in thousands of gallons). High throughput sites will have many deliveries and could cause temperature problems, reduced idle time and exceed recommended throughput limits.

Possible Causes

Programming

- Confirm correct thermal coefficient.

Gas: 0.00070 or 0.00069

Diesel: 0.00045 - Incorrect tank to line assignment, if the site has PLLD or pump sense, verify programming.

- Confirm siphoned and manifolded tanks are programmed correctly.

Hardware

- Confirm the pump’s relay is not stuck.

- Confirm the float is not stuck.

- Check the inventory report and compare the probe’s temperature to the other tanks at this site. Large temperature differences can indicate a probe issue.

- Check alarm history for probe or tank alarms.

Evaporation or Vacuum

Most tanks naturally build vacuum during the daytime and pressure at night. When the vacuum pressure increases, it draws fresh air into the tank through the pressure vent cap. This causes evaporation and results in a CSLD periodic test failure.

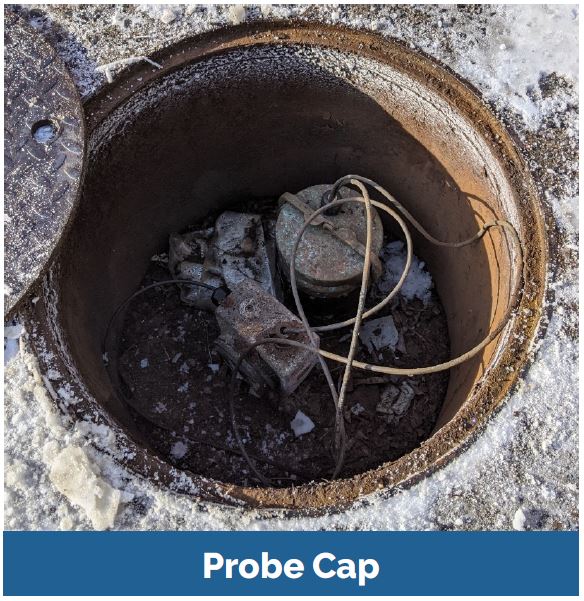

- Check all tank openings for possible venting issue – probe cap, fill cap, stage one dry break, spill bucket plunger.

- Verify the pressure vent cap is working properly.

Tank Issue

If troubleshooting the programming, hardware, and any evaporation or vacuum issues does not resolve the alarm then there maybe a tank leak.

- Run a 2-hour static test and review the results. If the test fails, call Veeder-Root Technical Support at 1-800-323-1799. It may be necessary to have a third-party test performed.

Further Information

- Contact Veeder-Root Technical Support at 1-800-323-1799 for additional help or questions.

- Learn more about CSLD and other features on our TLS-450PLUS Feature Enhancements webpage.

- Technical Support Notification - Troubleshooting CSLD – Periodic Test Fail (576047-376)