Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

It is important for retailers to understand consumer behavior to efficiently meet the demands of their customers. One aspect that is often taken for granted is the actual nozzle demand at the site and the implications that has on the sizing of Submersible Turbine Pumps (STPs) to ensure optimal performance. Veeder-Root, a leading provider of fuel management solutions, conducted a study that sheds light on the usage patterns of dispenser nozzles during peak times.

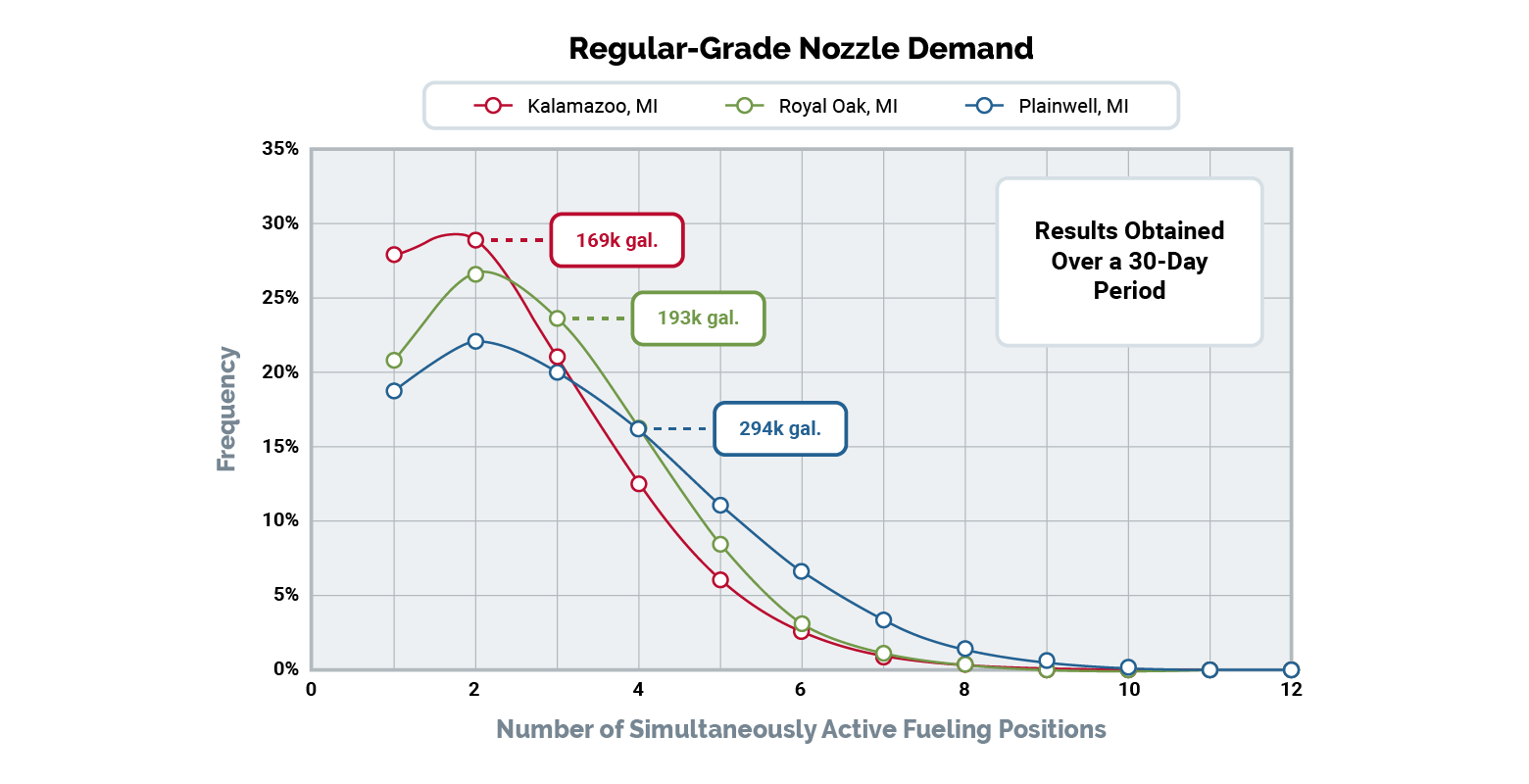

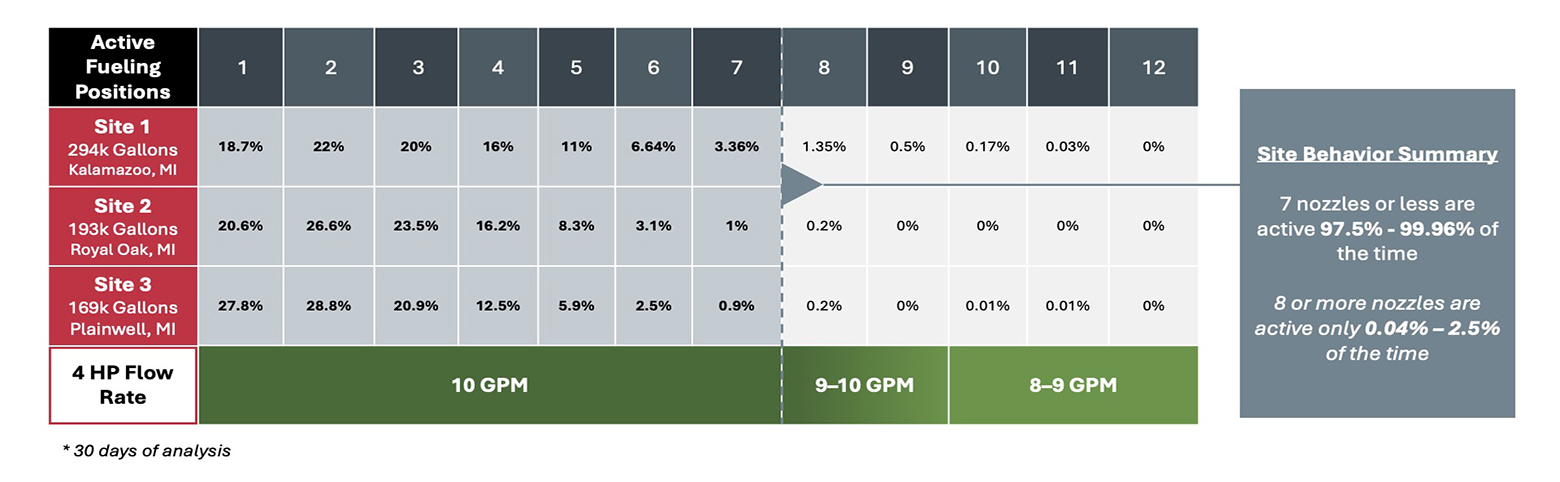

Three sites, each with 6 dispensers and 12 fueling positions, were selected for the study. The average throughput of those sites ranged from 169K Gallons Per Month (GPM) to 294K GPM. The assumption heading into the evaluation was that the higher throughput site must have a far greater number of nozzles active at a given time. The Veeder-Root study revealed interesting insights into consumer behavior and the actual number of nozzles active at a given time:

- 98% or more of the time 7 or less nozzles were active at the same time

- 0.2-1.8% of the time 8-9 nozzles were active at the same time

- 0.2% of the time or less, 10-12 nozzles were active at the same time

Regardless of site throughput, 98% or more of the fueling demand was provided by 7 or less active nozzles.

The reason behind the fact that not all nozzles are active can be attributed to various factors such as customers arriving at different times, variations in card transaction processing speeds, and/or customers temporarily leaving their vehicles parked at the dispenser. These statistics highlight the importance of understanding consumer behavior and sizing STPs accordingly.

The Red Jacket® 4 HP STP delivers 135 GPM flow rate capacity. It is expertly positioned to meet 98% of the sites’ throughput with 10 GPM at each active nozzle. It also delivers excellent performance of 8-9 GPM in the boundary cases where 8-12 nozzles are active.

Veeder-Root offers a range of solutions that address these specific needs. By utilizing the insights gained from the study, retailers can select the appropriate STP to accommodate the expected number of active nozzles during peak times, without over-specifying hardware for a situation that may never occur. This approach enables retailers to optimize their operations, minimize costs, and provide a seamless fueling experience to their customers.