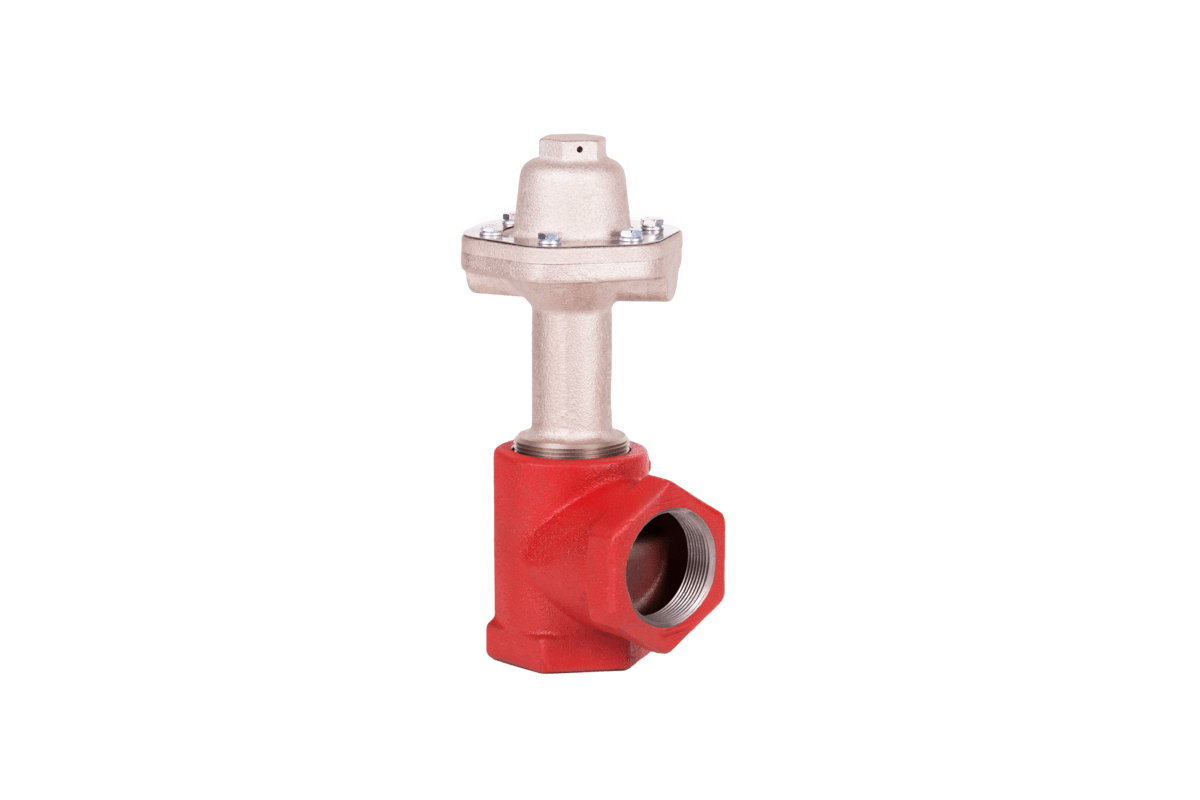

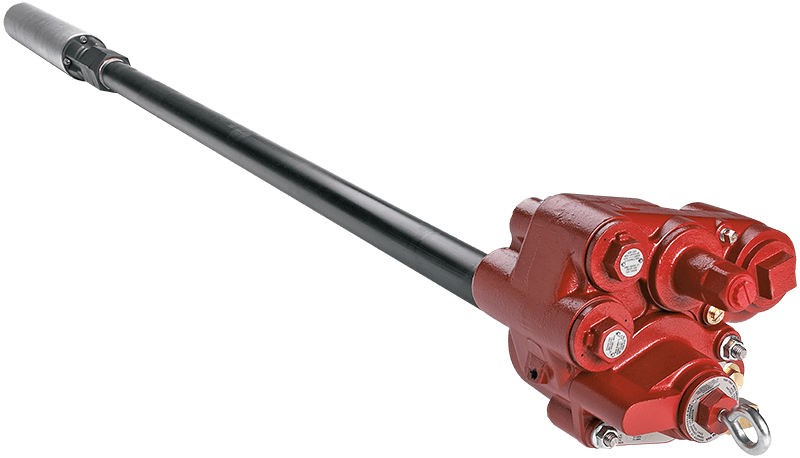

Non-Biofuel & Biofuel MLLDs

The Red Jacket® Non-Biofuel and Biofuel Mechanical Line Leak Detectors (MLLDs) are permanently installed in the packer manifold and interact with the fuel pathway, performing 3 Gallons Per Hour (GPH) / 11.4 Liters Per Hour (LPH) tests automatically. If a leak is detected, fuel flow is restricted to the dispensers.

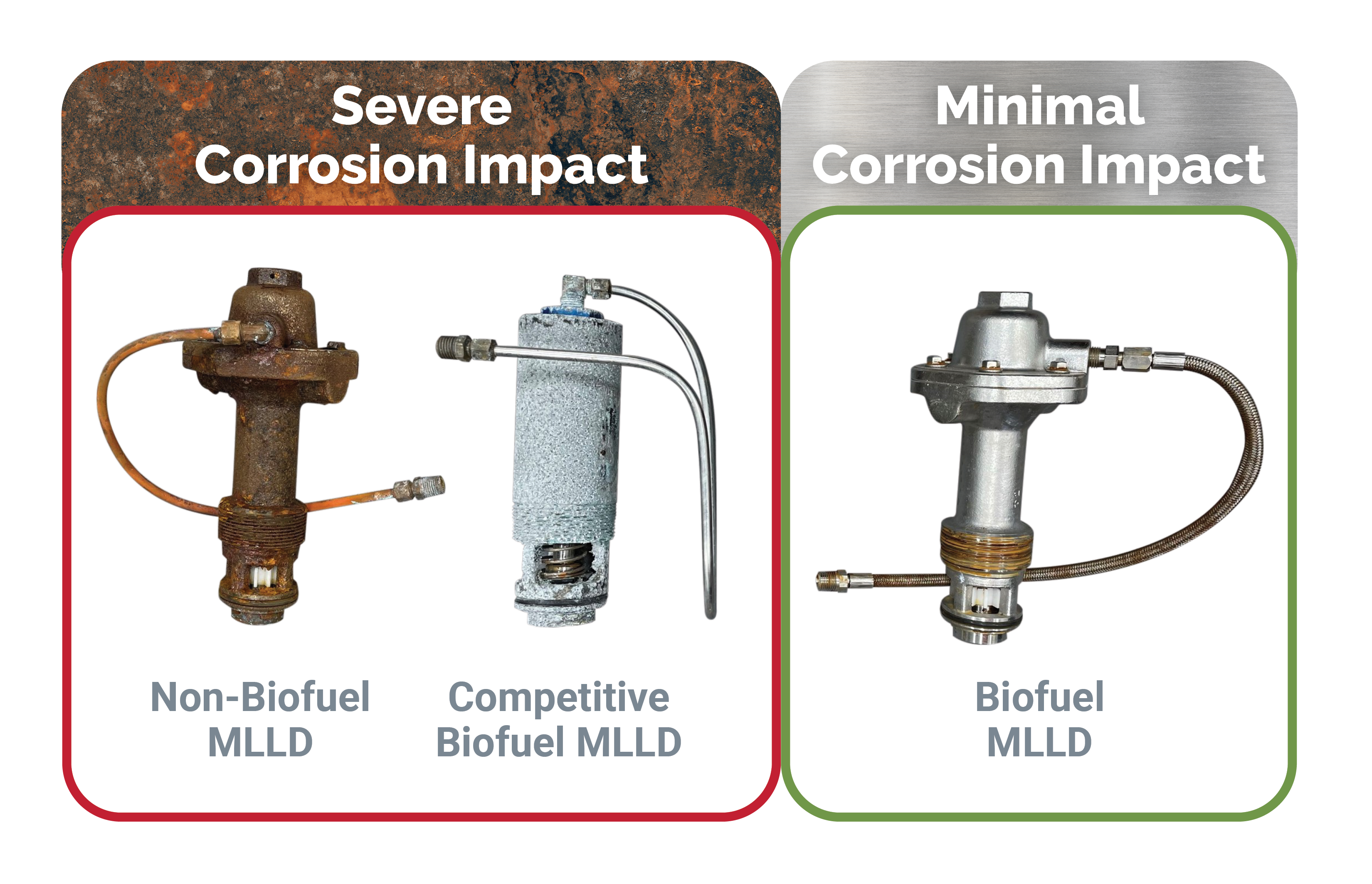

Protecting Your Site Infrastructure From Corrosion

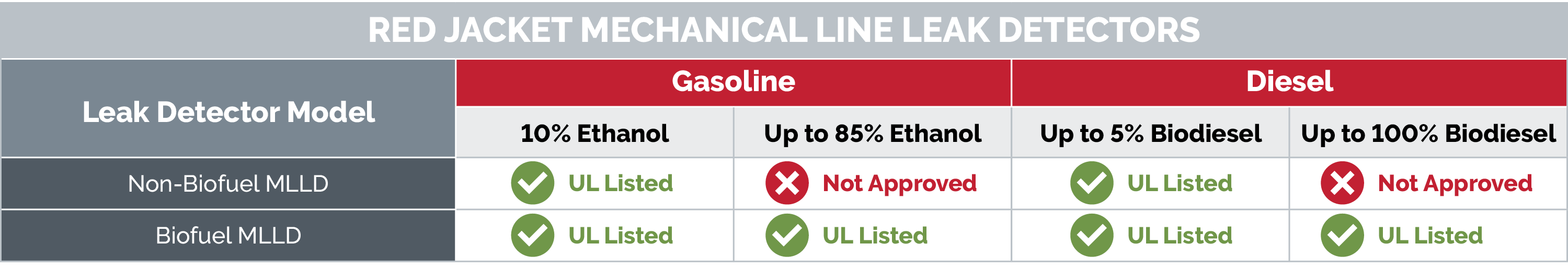

Corrosion of equipment in sump spaces can cause deterioration, negatively effecting a MLLD’s performance, potentially resulting in environmental issues and hazardous conditions. The Red Jacket Biofuel Mechanical Line Leak Detectors provide enhanced protection from corrosive condition. Its upgraded design includes a stainless steel body, cap, and machined components, to withstand the harshest corrosive environments.

28-Day Salt Fog/Humidity Chamber Test

The Red Jacket Biofuel MLLD was tested against the Red Jacket Non-Biofuel MLLD and a competitive Biofuel MLLD in a 28-Day Salt Spray evaluation, per ASTM G85. The testing results showed significant differences between both the competitive Biofuel MLLD and the Red Jacket Non-Biofuel MLLD, whereas the Red Jacket Biofuel MLLD showed minimal signs of corrosion.

Product Form

Part Number | Description |

001160565 | Line Leak Detector Unit, FX1V, Gasoline up to E10 |

001160585 | Line Leak Detector Unit, FX1DV, Diesel up to B5 |

0410981-001 | Line Leak Detector Unit, BFX1V, Gasoline up to E85 |

0410983-001 | Line Leak Detector Unit, BFX1DV, Gasoline up to B100 |

Features and Benefits

- Meets EPA requirements in environments that experience extreme temperature changes

- Robust design that works effectively in the most common and difficult testing environments

- Adapts to applications using high-resiliency lines, such as flexible piping

- Handles up to 11 feet / 3.4 meters of static head pressure

- No special tools required for installations and annual checks

- Compatible with any Red Jacket or competitive submersible turbine pump

Specifications

Certification | UL Listed |

Types of Pipelines | Fiberglass, steel, double wall, flexible, semirigid, or any rigid piping |

Nominal Diameter of Pipeline | 10 inches or less / 25.4 centimeters or less |

Maximum Installation Line System Size | 416.7 gallons / 1,577.3 liters for rigid lines and 95.4 gallons / 361 liters for flexible lines |

Maximum Operating Pressure | 50 PSI / 3.4 bar |

Pipeline Leak Threshold | 1.5 GPH / 5.7 LPH @ 10 PSI / 0.7 bar at operating pressure |

Documents

- The Red Jacket Biofuel Mechanical Line Leak Detector Datasheet (576047-475)

- FX1V and FX2V Leak Detectors - Certification Reports, Results of U.S. EPA Standard Evaluations (577013-872)

- FXV Leak Detectors Installation Instructions (042-106-1)

- Testing Mechanical Leak Detectors - FX Tester (C051-272)

- Testing Mechanical Leak Detectors - Option B Finite Testing (RJ-20)

- Red Jacket Product Guide (576047-310)