Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

When you visit an EZ GO travel center in central Oklahoma, you have options – a lot of options. Their variety of products, food and fuel alike, is central to the brand’s strategy. Offering choices can be complicated, but as EZ GO found out, solutions like our Additive Injection System can help turn a strategy into sustained success.

Fuel runs in EZ GO President Carey Johnson’s blood and he knows what works. His father started the company as a wholesale fuel business in 1963. Twenty years later, the first retail stores were built and EZ GO was born.

PREMIUM OPPORTUNITY

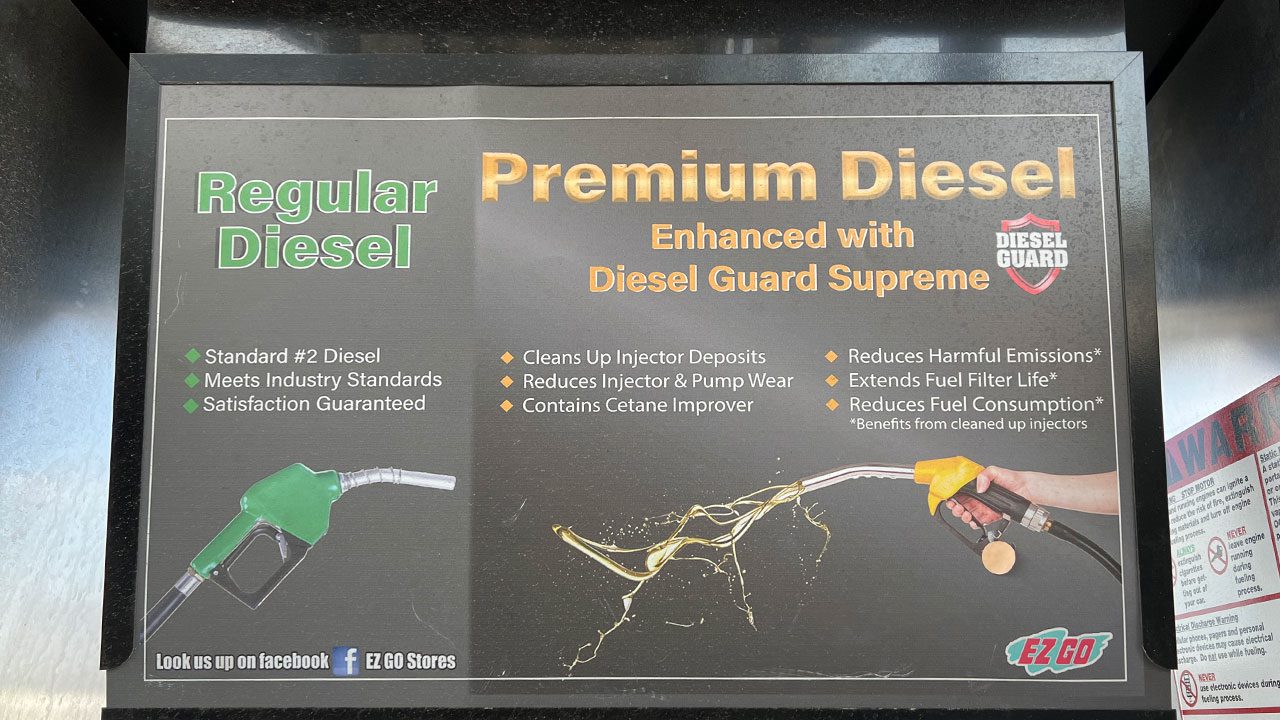

When Johnson says he focuses on fuel variety and quality for his customers, he means all his customers – commercial drivers included. Unlike many travel centers in the area, EZ GO offers premium grade diesel.

“It’s always been strange to me that if you drive a gasoline vehicle, you can pull up anywhere and have lots of choices,” Johnson says. “But no one seems to offer choices to the diesel customer.”

Johnson’s idea isn’t just a theory. Fuel quality ranks among the top five reasons drivers stop at a gas station – along with good lighting, clean bathrooms, and other amenities, according to NACS. For professional drivers, their vehicle can be their livelihood, making fuel quality even more critical.

PREMIUM PROBLEM

While EZ GO’s strategy is sound, they discovered execution would be the challenge. Johnson started hitting the same barriers other brands hit when trying to offer top quality fuel: availability and cost.

“We looked at the wholesale terminal for the kind of diesel we wanted to offer. It was not reliably available, let’s say,” Johnson says. “So, we were doing this manually and it’s a messy business to add your own additive.”

What does Johnson mean by “messy business”? His employees know first-hand. To provide premium grade diesel, EZ GO must add extra additives to each fuel delivery. This means an employee must walk outside for each fuel drop, measure chemicals, and dump the solution into the tank through a funnel manually. Once the cumbersome process is done, the driver can make the delivery.

“We have to wait on customers. We have to make coffee,” says store manager, Cassandra Tyler. “And yeah, we don’t want to [dump the additives] – especially when it’s snowing.”

Johnson started searching for a way to simplify the process and unload these employee burdens, so he reached out to us for help.

PREMIUM SOLUTION

The Additive Injection System, developed by Veeder-Root and Total Meter Services (TMS), is designed to overcome the challenges brands face when trying to source high quality fuel.

For EZ GO, availability was the barrier. For others, the cost for custom blends at the rack is the problem. Sites can save $0.02 - $0.03 per gallon by starting an on-site fuel additive program, compared to buying additized fuel at the rack. For a site that sells 10,000 gallons a day, that could mean an annual savings of $73,000.

“The system has provided tremendous value to sites that used to manually treat tanks and offer premium grades of fuel that their competition cannot,” says Kevin Jensen, Vice President of Sales, TMS.

The AIS continuously monitors for fuel movement. When a delivery is detected, the AIS Controller will instantly calculate the amount of additive needed for each product or tank and immediately begin treatments. The system injects additive every few seconds directly into the flow stream, resulting in hundreds of small injections over the course of the delivery.

“With the AIS, it’s easy to receive diesel,” Johnson says. “Having it all online and dropped automatically with each delivery is definitely an advantage.”

It didn’t take long for the rest of EZ GO’s employees to notice the benefits from the AIS either.

“I like [the AIS] a lot better,” says Tyler. “I don’t have to go out and smell stinky chemicals.”

PREMIUM RESULTS

The results of the AIS aren’t limited to happier employees, EZ GO customers have caught on as well. Johnson has used the system and his high-quality blends to strengthen the brand’s reputation and customer loyalty.

“We have [premium diesel] at two of our turnpike sites now and truckers definitely talk about it,” Johnson says. “They reward us with a pretty good percentage of our overall diesel sales going through that premium channel.”

EZ GO’s focus on fuel quality has led to increased business, but it’s not all about the bottom line. For Johnson and his company, the boost in business comes from serving customers and giving them convenient choices.

“That’s the reason why we went for this system. Because our mission is to delight customers and earn their loyalty,” Johnson explains. “We like it simple that way because it gets right to the core of what we do. That simple statement is something that we live and breathe, and hopefully execute on a daily basis.”

To learn more about our AIS, click here.

Ask your local Veeder-Root distributor about the Additive Injection System today!