Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

When consumers drive onto any forecourt, they expect fuel that not only powers their vehicles but protects them as well. Committing to a high-quality fuel strategy saves drivers’ engines and saves you money as a retailer – all while elevating your brand.

Approximately six in ten drivers (63%) believe there is a difference in the quality of gasoline sold by retailers, according to AAA. Quality is dictated by several factors, but one of the most important is additives. Designed to keep engine components cleaner, additized fuel results in:

-

Lower emissions

-

Improved fuel economy

-

More power to the vehicle

THE DIRT ON ADDITIVE REGULATIONS

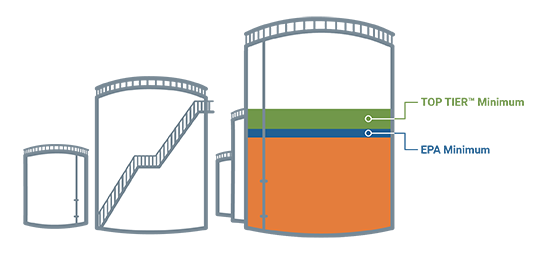

In 1995, the U.S. Environmental Protection Agency set minimum performance standards for additives, allowing gasoline retailers to reduce the concentration of detergents in market gasoline by up to 50%.

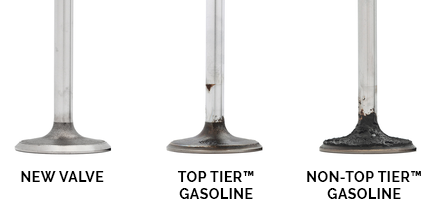

What happened next shows why fuel quality is so important to everyone on the road. Automakers soon discovered increased incidents of poor performance and engine damage. Further research showed that the EPA’s minimum requirements were not sufficient for use in modern vehicles, causing the world’s top car manufacturers to create an optimal standard known as TOP TIER™ Detergent Gasoline.

Engines using TOP TIER gasoline average 19 times fewer intake valve deposits than engines using non-TOP TIER fuel, according to a AAA study. Long-term use of gasoline without the appropriate additives can lead to fuel economy reductions of 2-4%.

The importance of additives and their role in high-quality fuel is easy to see, but TOP TIER-compliant fuel can be challenging to source. Many retailers simply don’t have access to terminals or struggle to service remote areas. Even with access, they face higher costs to create these custom blends at the rack.

BYOB: BRING YOUR OWN BLEND

The most efficient way to solve these problems is through the Additive Injection System (AIS), offered in partnership by Veeder-Root and Total Meter Services (TMS), which gives retailers automated control over the additization process. The AIS is a complete solution that delivers a premium fuel program across your network and integrates with Veeder-Root TLS Automatic Tank Gauges (ATGs) to automate the injection process.

With the AIS, marketers can treat low quality fuel with premium additives to achieve the highest standards – the perfect tool for emerging markets. The AIS Cloud provides access to configure and manage the system remotely. When a delivery driver makes a fuel drop, the AIS precisely injects your specific additive formula into the fuel throughout the drop. No special directions for the driver are necessary.

The AIS is a flexible, scalable solution that works with any additive tank type and size. It improves safety and eliminates human error involved with manually dosing tanks with additives.

AIS MAKES CENT$

Besides operational efficiency, the AIS is also cost-efficient. An on-site fuel additive program typically yields savings of $0.02 - $0.03 per gallon, as compared to additized fuel at the rack.

Creating additized fuel on-site provides a variety of smart advantages that help your customers, your operations, and your bottom line. The AIS makes it easier and cheaper to differentiate your brand, drive consumer loyalty and commit to a high-quality fuel strategy that impacts everyone for the better.

To learn more about our AIS, click here.

Ask your local Veeder-Root distributor about the Additive Injection System today!

TOP TIER™ is a trademark of General Motors LLC.