Printing 3D Masks

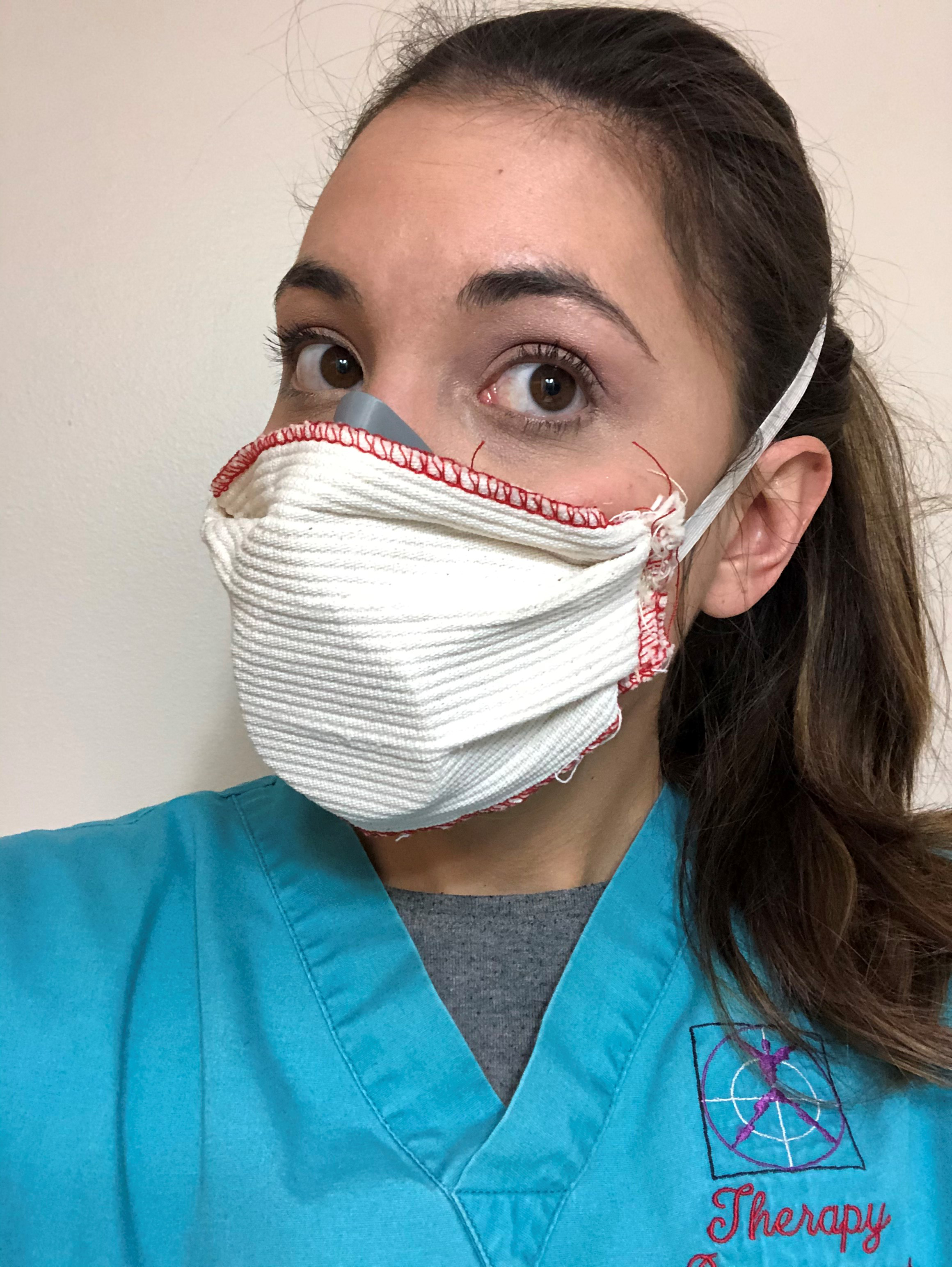

Wanting to give his wife an improved mask, he researched 3D mask designs, and located one developed by a doctor that are washable and reusable. He then setup his home 3D printer, generated the print profile, and then printed and tested the prototype mask. She wore it under her reusable mask and said she believed it was an improvement to her current PPE.

He offered these masks for free through his own inventory to anyone who may want to have it as a backup. With the support of the Veeder-Root Altoona factory he was able to continue to make 16 more masks for other essential workers at local hospitals who are looking for an alternative, or who have no other options available.

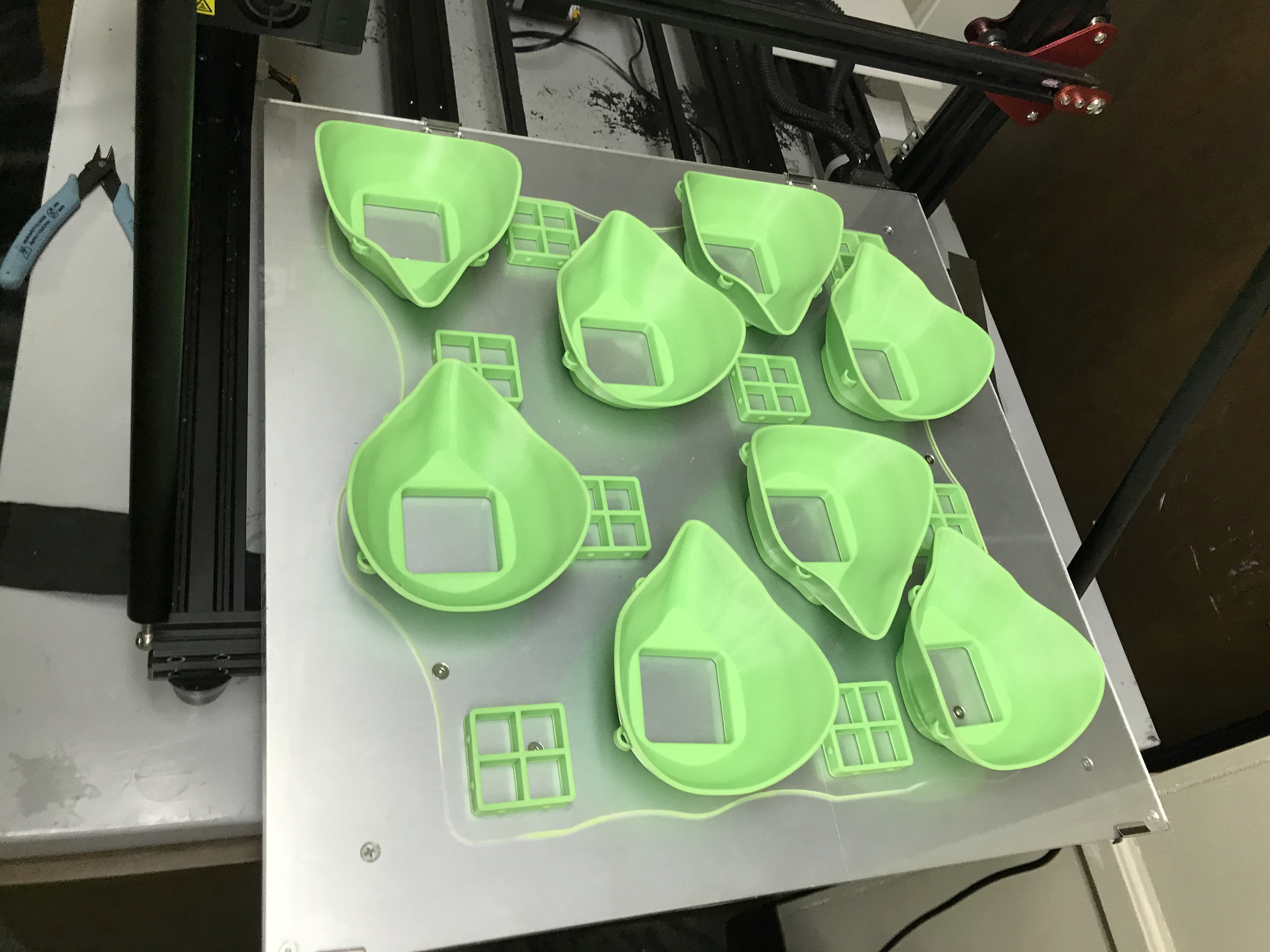

In addition to printing masks, the team is also making ear savers on the 3D printer. The ear savers work with almost any mask by removing the pressure of the elastic from the back of the ears. Over 100 ear savers have been made at the Altoona factory and continue to be made. They are being used by team members in the factory and many have been donated to hospitals and other healthcare workers.

This equipment has offered a little peace of mind to some in these unprecedented times. The actions of these Veeder-Root individuals is a testament to their character and can-do determination. Better Begins Today.