WHAT IS SUMP-DRI?

The Red Jacket® Sump-Dri™ Desiccant System is uniquely formulated to protect sump-space equipment from corrosion by reducing relative humidity and neutralizing the acetic acid vapors naturally created by the combination of water, bacteria and various alternate fuel blends. By reducing corrosion, Sump-Dri helps ensure safety and extend the life of components contained in the sump.

SEE THE DIFFERENCE

“We implemented Sump-Dri because we recognize that water is the enemy. We will take any opportunity we can to remove moisture from the sump to keep our equipment running optimally.” - Paul Beu, Senior Petroleum Systems Technical Advisor, Wawa

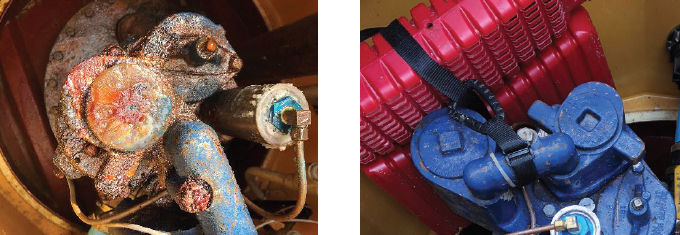

Left Image: Effects of In-Sump Corrosion, Right Image: Sump-Dri Installation Combating Corrosion

COMBATING CORROSION AT THE SOURCE

Veeder-Root partnered with Wawa in field testing of its newly developed Red Jacket® Sump-Dri™ Desiccant System with confidence that it would alleviate the industry’s nagging corrosion issues. Veeder-Root began testing in the northeast region, which experiences high humidity levels during peak summer months, and continued with Wawa in Florida, with its year-round tropical climate, warm temperatures, high humidity and high rainfall. These conditions are capable of producing the most extreme corrosive environments and were ideal for evaluating performance in the “worst case” scenarios. Despite varying geographic locations, each test site was experiencing remarkably similar problems. Equipment was suffering from severe corrosion, resulting in poor sealing and increased susceptibility to water ingress. Consistent results from this year long field testing, indicated the average replacement cycle of the Sump-Dri (average of 3 to 6 months). At the end of our trials, we concluded that our proprietary desiccant system mitigated residual acidic conditions and avoided the subsequent condensation of water and fuel vapors.

“We have eliminated the essential conditions required for bacterial growth and aggressive in-sump corrosion.” - Ken Cornett, Principal Scientist at Veeder-Root

ONE YEAR LATER, THE RESULTS ARE CLEAR

At the conclusion of the study the results were clear: Sites with the Sump-Dri installed had more sustainable conditions within the sump space, including limited condensation on the equipment, reduced levels of humidity and low acetic acid concentration in the vapor space. In sump spaces that were not installed with the Sump-Dri at the same site, accelerated corrosion on the equipment, extreme condensation, high levels of humidity and high acetic acid concentrations were all present.

“Sump-Dri ensures all of the equipment continues to operate at optimal levels. It eliminates potential down-time and loss of sales that any pump made inoperable by corrosion would cause.” - Paul Beu, Senior Petroleum Systems Technical Advisor, Wawa

REGULAR UNLEADED WITHOUT SUMP-DRI INSTALLED

• Accelerated corrosion

• Extreme condensation

• Humidity above 60% causing high corrosion rates

• Acetic Acid vapor saturation

• Safety concerns

• Service complications

REGULAR UNLEADED WITH SUMP-DRI INSTALLED

• Limited corrosion

• Reduced condensation

• Low corrosion rate humidity, averaging 40%

• No acetic acid

• Improved safety

• Improved serviceability

KEY TAKEAWAYS:

1. THE COST OF CORROSION IS HIGH

Not only does corrosion of the STP sump environment lead to potentially dangerous environmental conditions, it exposes businesses to the risk of pump downtime and sales losses.

Sump-Dri offers a simple solution that, when installed and serviced properly, prevents potential leaks, premature pump failure, unserviceable parts, and reduction to the overall equipment lifespan of the equipment. It protects the serviceability of the STP and its components, along with potential contamination to the infrastructure.

2. REDUCING CORROSION IS A COMPETITIVE ADVANTAGE

Sump-Dri is simple to install, easy to maintain, and offers a much lower cost than subsequent repair and replacement measures.

3. CREATING AN OPTIMAL ENVIRONMENT PRESERVES YOUR INVESTMENTS

By reducing corrosion, Sump-Dri helps maximize the utility and longevity of equipment, reducing profit loss, overcoming environmental constraints, and promoting public safety.