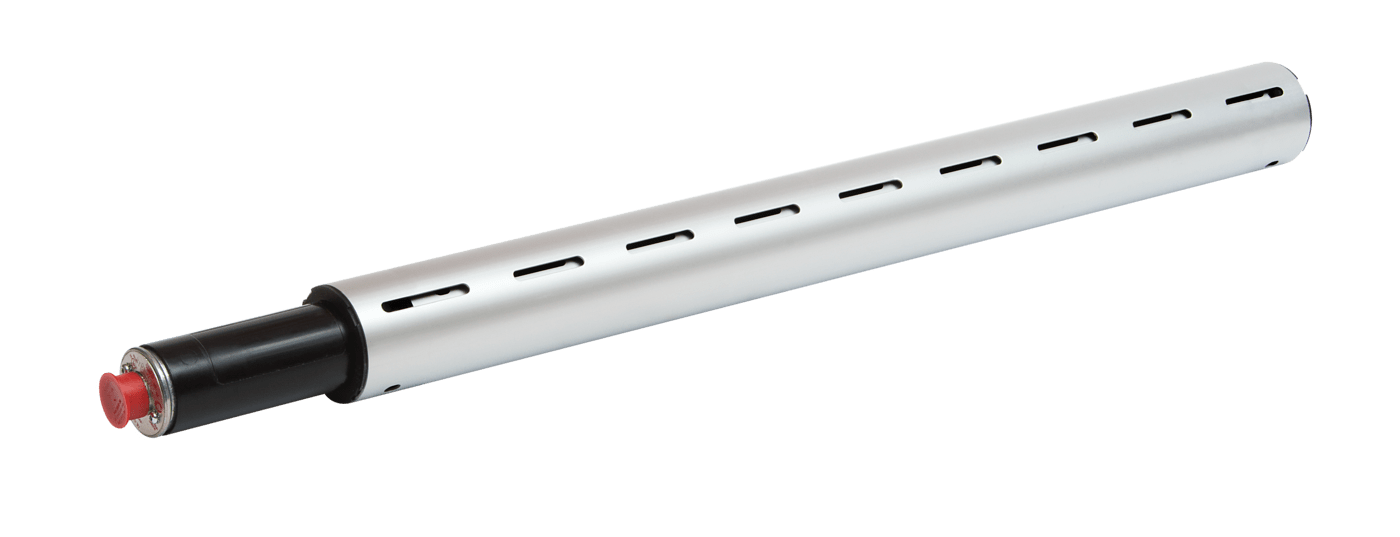

Mag Sump Sensor

Quickly and accurately detect the presence and the amount of water and/or fuel in the containment sump or dispenser pan. Using proven magnetostrictive technology to detect hydrocarbons or water, the Mag Sump Sensor produces fast reaction and recovery times, which eliminates costly and unwarranted service calls and sensor replacements. Its high-grade polymer housing provides enhanced corrosion resistance and fuel compatibility.

The Mag Sump Sensor also allows for quick and easy periodic operability testing using the Sump Integrity Testing feature, if required by local agencies.

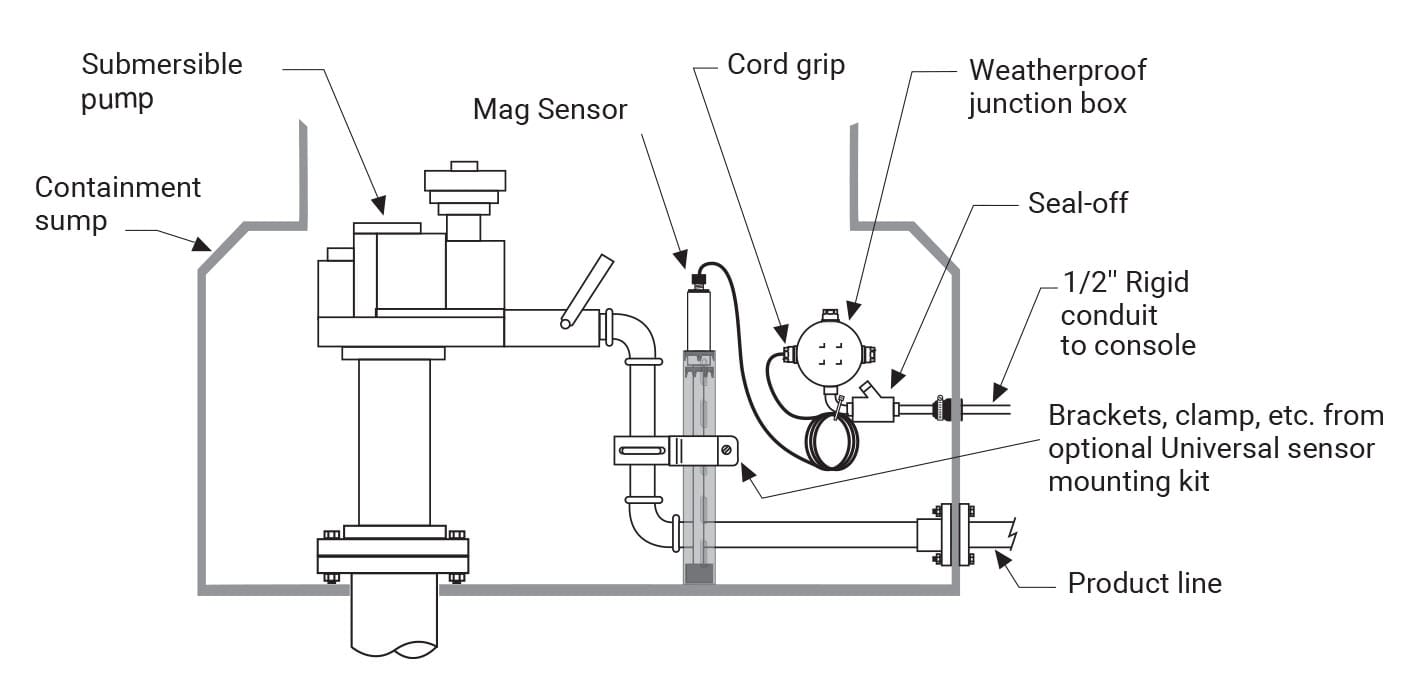

Continuously Monitor Sumps

Where continuous monitoring of the sensor position is required by law, site owners are immediately notified if the sensor has been moved from its proper position at the bottom of the containment sump or dispenser pan.

Alarm conditions are indicated by an audible alarm and displayed message on the Automatic Tank Gauge console and are recorded as a part of the Alarm History Report.

Product Form

Part Number | Description |

857080-111 | 12” Mag Sump Sensor |

857080-112 | 24” Mag Sump Sensor |

857080-211 | 12” Mag Sump Sensor w/ Sump Integrity Testing |

857080-212 | 24” Mag Sump Sensor w/ Sump Integrity Testing |

330020-012 | Universal Sensor Mounting Kit (Sold separately |

Key Features

- Straight-forward alarm notification upon presence of liquid in your containment area

- Detect and pinpoint fluid type in containment areas to allow for smart dispatching

- High-grade polymer housing provides enhanced corrosion resistance and fuel compatibility

- Increased site uptime in locations where shut down is not required if only water is detected

- Single module for two- and three-wire sensors provides greater flexibility for users to monitor multiple sensor types

- Delivers extended performance in harsh conditions

- Alarm conditions indicated by audible alarm, displayed and printed message

- Record of past alarms available as part of Alarm History Report with TLS-4xx series consoles

- Robust and rugged screw-in connector allows simplified installation and trouble free inspection.

Specifications

Fuel Compatibility | Gas, Diesel, Kerosene, Jet Fuel, Aviation Gas, E15, E85, E100, Bio-Diesel 20, Bio-Diesel 100, Green Diesel, DEF, Waste Oil, Motor Oil |

Alarm Notification | Normal: Sensor in Normal State – No liquid detected |

Water Alarm: Water detected at minimum of 1.614” (2.83cm) | |

Fuel Alarm: Fuel detected at minimum of 1.368” (3.47cm) | |

Sensor Out: Sensor not communicating with ATG Console | |

Operating Principle | Magnetostrictive probe with dual floats |

Product Activation Height | Water 1.614” (4.1cm), Fuel 1.368” (3.47cm) |

Operating Temp | -40°C to +60°C |

Dimensions | 2.4” (6.1cm) Diameter; 21.4” (54.4cm) Long (-111 and -211 models), 33.4” (84.8cm) Long (-112 and -212 models) |

Cable Length | 10 feet |