Maximize Protection of Secondary Containment

The Veeder-Root Secondary Containment Sensing System was designed to meet several regulatory requirements that require a vacuum on secondary containment system. This technology can be used across multiple platforms such as, retail, marina’s, commercial and industrial applications.

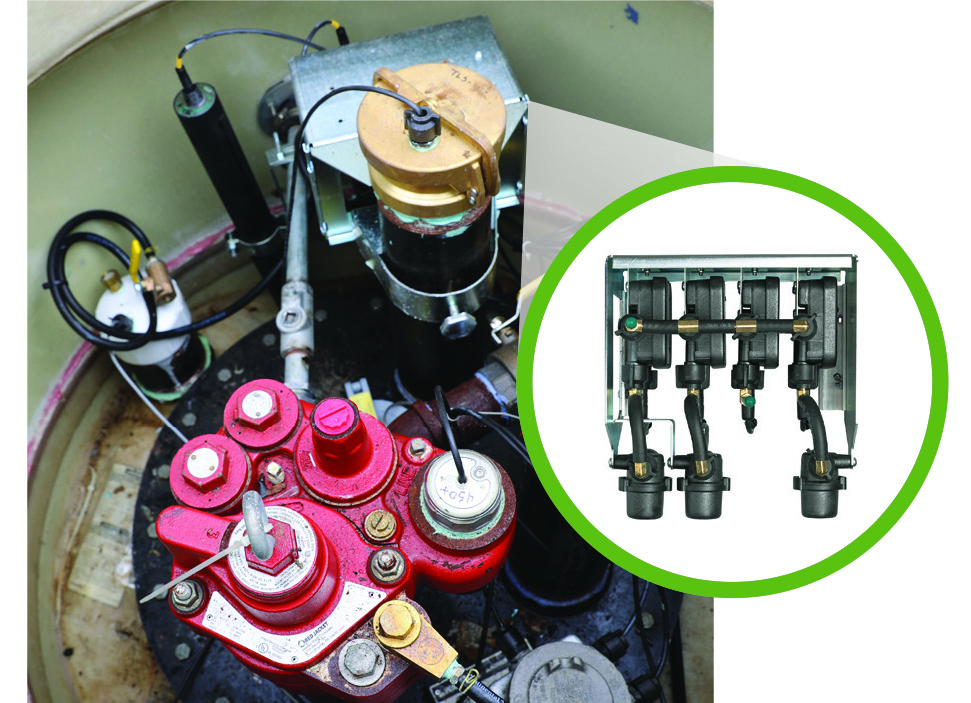

The Secondary Containment Vacuum Sensing System (SCVS) detects even the smallest leaks, preventing them from entering the environment — costing you money on repairs. Using installed submersible turbine pumps (STPs), a vacuum seal is created, which closes the interstitial spaces of your tanks, piping, sumps, and pans. Only available for new constructions sites.

Key Benefits

- Maximized protection with a vacuum-monitored secondary containment system

- Reduces exposure to risk by sending an alarm to your tank gauge when vacuum seal cannot be maintained

- System alarms you when liquid is detected in secondary space

- Facilitates periodic operability testing and simple to install

Certified for Use

- Certified to meet California's requirement for secondary space monitoring for tanks and lines as required by AB 2481

- Satisfies the requirements for Class I Leak Detection as defined by the European Standard EN 13160-2

- 3rd Party, National Work Group and LG113 listed

Operating Temperature Rating: -25 degrees C to +70 degrees C

The Vacuum Sensor is compatible with the following consoles:

- TLS-450PLUS ATG*

- TLS-350R ATG w/BIR**

- TLS-350PLUS ATG**

- TLS-350 ATG

*Supported with Version 9.A and higher software

**Upgrade Note: The Vacuum Sensor System requires the console to have version 24C software (or greater) along with an ECPU2 or ECPU w/ NVMEM 1 board.

Product Form

Monitored Items: 1 Tank & 3 Pipelines/Sumps | |

Part Number | Description |

330020-471 | Vacuum Sensing System (SCVS) 4 Vacuum Sensor kit, up to 10' diameter fiberglass |

330020-467 | Vacuum Sensing System (SCVS) 4 Vacuum Sensor kit, steel tanks |

Monitored Items: 1 Tank & 2 Pipelines/Sumps | |

Part Number | Description |

330020-476 | Vacuum Sensing System (SCVS) 3 Vacuum Sensor kit, up to 10' dia. fiberglass |

330020-472 | Vacuum Sensing System (SCVS) 3 Vacuum Sensor kit, steel tanks |

Monitored Items: 1 Tank & 1 Pipelines/Sumps | |

| Part Number | Description |

330020-484 | Vacuum Sensing System (SCVS) 2 Vacuum Sensor kit, up to 10' diameter fiberglass |

330020-479 | Vacuum Sensing System (SCVS) 2 Vacuum Sensor kit, steel tanks |

Monitored Items: 1 Tank & No Pipelines/Sumps | |

| Part Number | Description |

330020-549 | Vacuum Sensing System (SCVS) 1 Vacuum Sensor kit |

Monitored Items: No Tank Vacuum Sensor Kits | |

| Part Number | Description |

330020-486 | Vacuum Sensing System (SCVS) 4 Vacuum Sensor kit, no tank - 4 pipes/sumps |

330020-485 | Vacuum Sensing System (SCVS) 3 Vacuum Sensor kit, no tank - 3 pipes/sumps |

330020-480 | Vacuum Sensing System (SCVS) 2 Vacuum Sensor kit, no tank - 2 pipes/sumps |

330020-495 | Vacuum Sensing System (SCVS) 2 Vacuum Sensor kit, no tank - 2 pipes/sumps |

Kits come pre-assembled and include mounting bracket, 6’ of vacuum hose, relief valve assembly (if required), steel or fiberglass tank riser cap (if required) and the appropriate number and type of liquid sensors, 3-way plastic ball valves, barbed fittings, hose clamps, etc. so that each vacuum sensor can monitor a single tank, sump or piping interstice. | |

Vacuum Sensor Modules | |

| Part Number | Description |

332250-001 | Seven-Input Smart Sensor Module w/Embedded Pressure Sensor Interface for |

329356-004 | Module, Eight-Input Smart Sensor (for use with Smart Sensors) |

The Vacuum Sensing System requires one Seven-Input Smart Sensor Module with Embedded Pressure Sensor interface. For more than seven sensors, add an additional Eight-Input Smart Sensor Module. Both can also be used with Mag Sump Sensors. | |

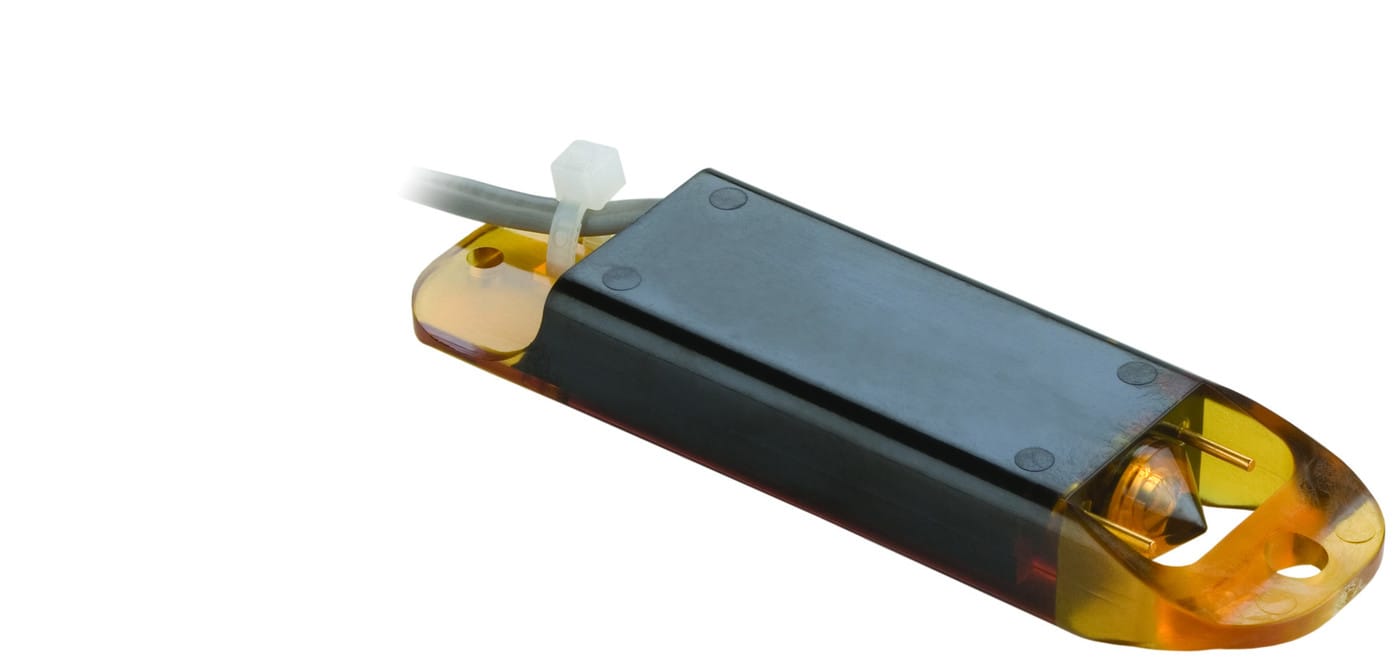

Vacuum Sensor Single Sensors (Unassembled) | |

| Part Number | Description |

857280-100 | Vacuum Sensor for piping & sumps (1 pipe or 1 sump) |

857280-200 | Vacuum Sensor for 1 steel tank |

857280-304 | Vacuum Sensor Single for up to 10' diameter fiberglass tank (1 fiberglass tank) |

330020-448 | Vacuum Sensor Mounting Kit (up to 4 sensors) |

332217-002 | Vacuum Sensor Relief Valve Assembly (required for fiberglass tanks) |

Single Vacuum Sensors come unassembled – mounting kits as well as relief valve assembly (if required) must be purchased separately. Pre-assembled kits are recommended if monitoring more than one interstitial space per STP. | |

| TLS-450PLUS USM and UIOM Modules | |

Part Number | Description |

332812-006 | Universal Sensor / Probe Interface Module (USM)Module for TLS-450PLUS |

| 330020-846 | Kit - USM/ATM Module |

330020-847 | Kit - ATM Pressure Board |

| 332813-001 | Universal Input/Output Interface Module (UIOM) |

| A USM is required to connect the Vacuum Sensors and Liquid Sensors. A UIOM is required to connect Red Jacket pump relays for pump control and the hook-off signal. | |

| TLS-450PLUS Software Enhancement | |

Part Number | Description |

332972-029 | Software Enhancement Feature - Secondary Containment Vacuum Monitoring (SCVS) |

Key Features

- Vacuum Alarm: Alarms when vacuum cannot be maintained or when replenish rate exceeds 85 liters per hour – prevents leak from entering environment, reducing site’s exposure to costly repairs

- Liquid Alarm: Alarms when liquid is detected in the secondary space – early notification of leak allows users to react and fix the potential issue before it reaches the environment

- Simple Installation: Installs in STP sump and connects to the console through intrinsically safe wiring

- Operability Testing: Facilitates periodic tests leveraging existing Veeder-Root systems