Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

Overview

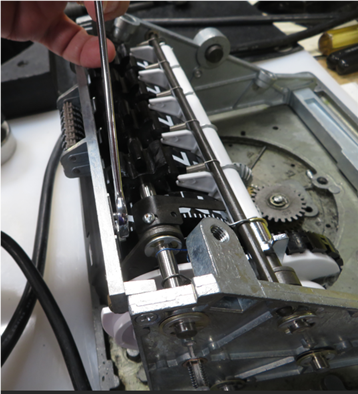

This notification provides instruction on the proper way to reset a mechanical register when not mounted to a meter and resetting the tip pointer to zero position.

Impacted Equipment: All Mechanical Registers

Reset:

- It is not common to need to reset a mechanical register when it is not installed on a meter.

- During shipment, the bevel gear may rotate due to vibration. When this occurs, the arrow may not be on zero.

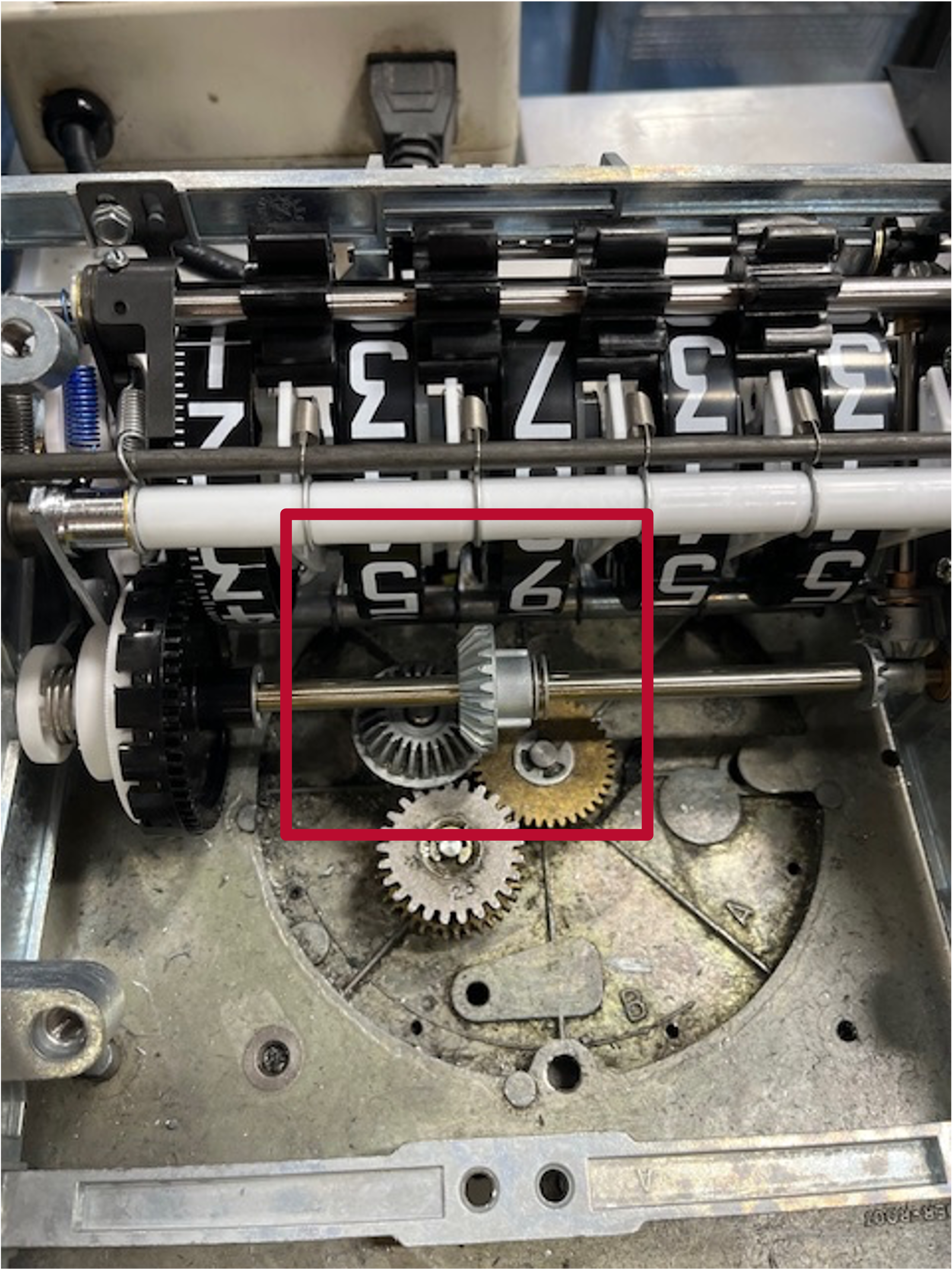

- If you need to reset a non-installed register, you need to prevent the bevel gear (red box) from rotation during the reset.

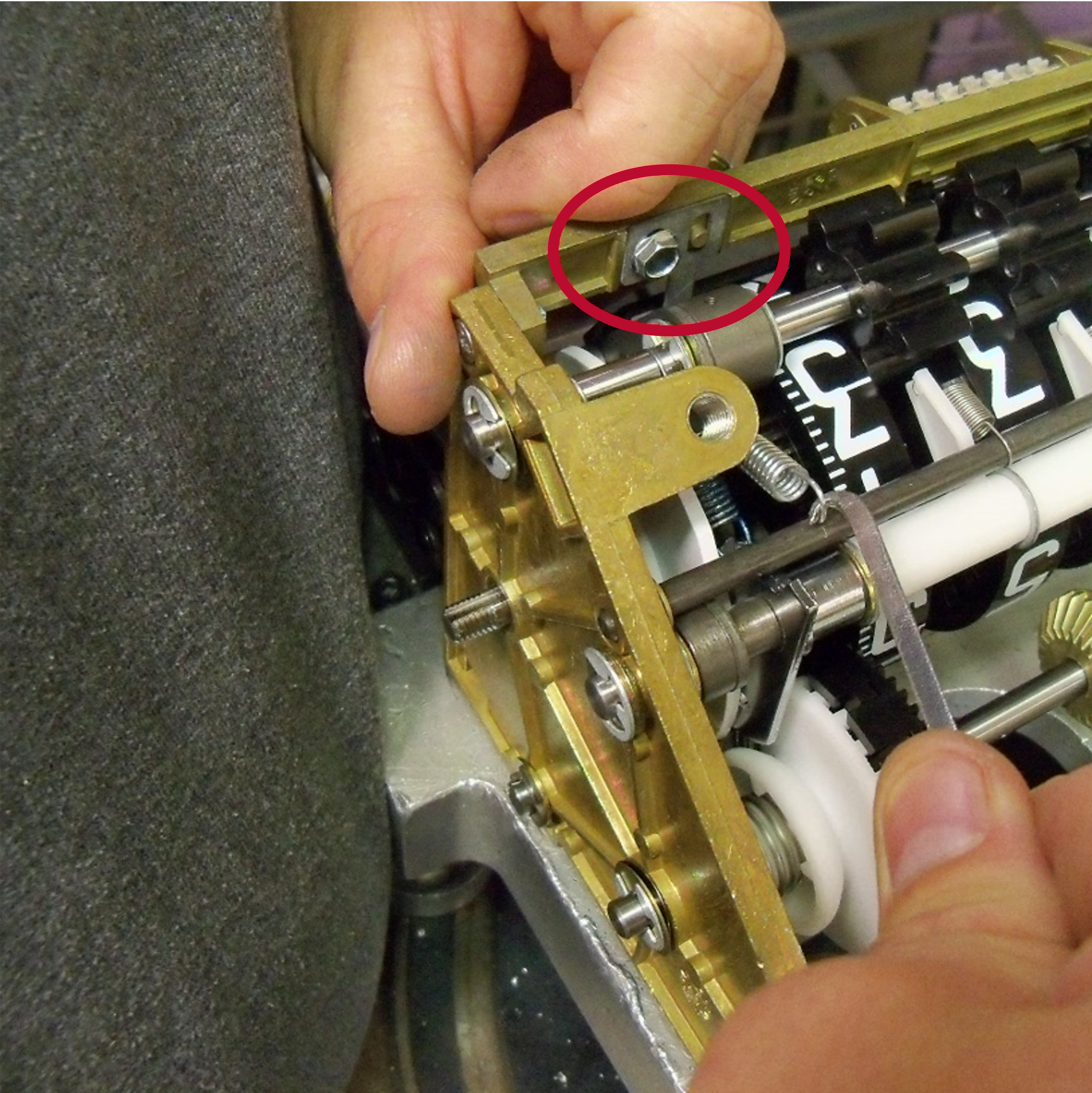

- Hold the pinion gear with a cloth using your hand to prevent movement.

Zero Pointer Adjustment:

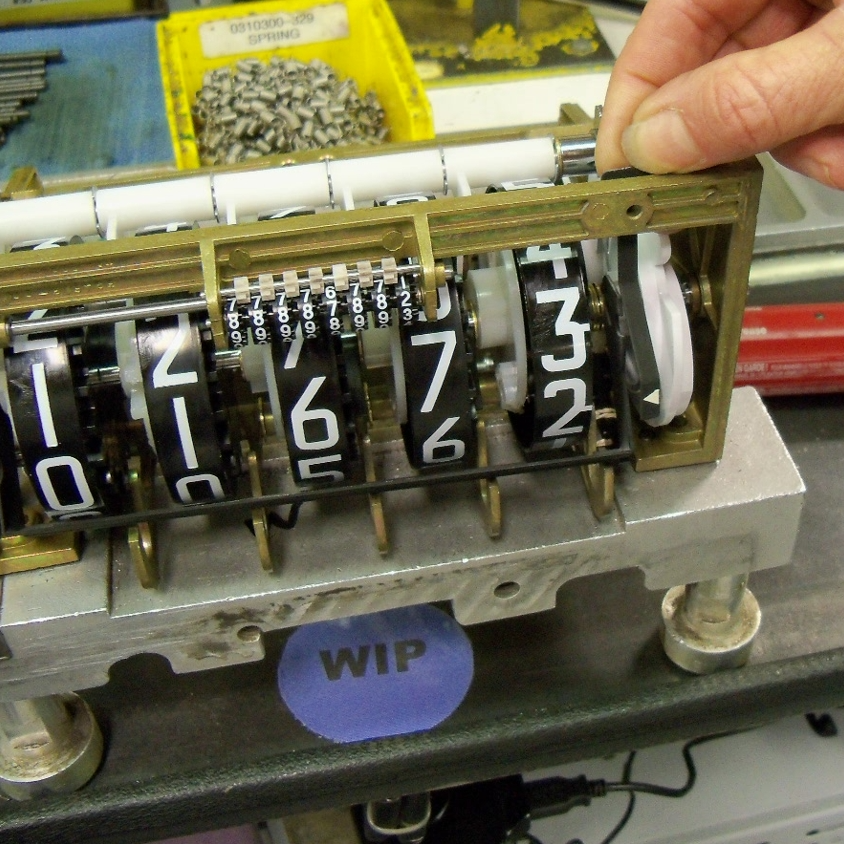

- For best results, the register should be mounted to a gear plate to prevent any movement during the reset.

- Reset the register several times to determine the average position of the zero-graduation relative to the tip of the pointer.

- Adjust the tip of the pointer referenced to the average zero position.

- Acceptable offset would be +/- 3/32” on the right wheel.

- +/1 1 graduation on the right wheel with 100 graduations.

|  |  |  |

Questions

If you have any questions, please call the Veeder-Root Technical Support team at +1.800.323.1799.