The components of the HydrX Fuel Conditioning System are customized based on the unique configuration of each diesel storage tank. Ensure that your site meets the requirements ahead of ordering.

Site Requirements

- Ability to pull 5 wires in the high voltage conduit (2 high power wires, 2 neutral wires, and 1 ground wire) and 2 Intrinsically Safe (IS) pairs.

- Two open spaces in the gas electrical panel to accommodate a 15-Amp switched neutral.

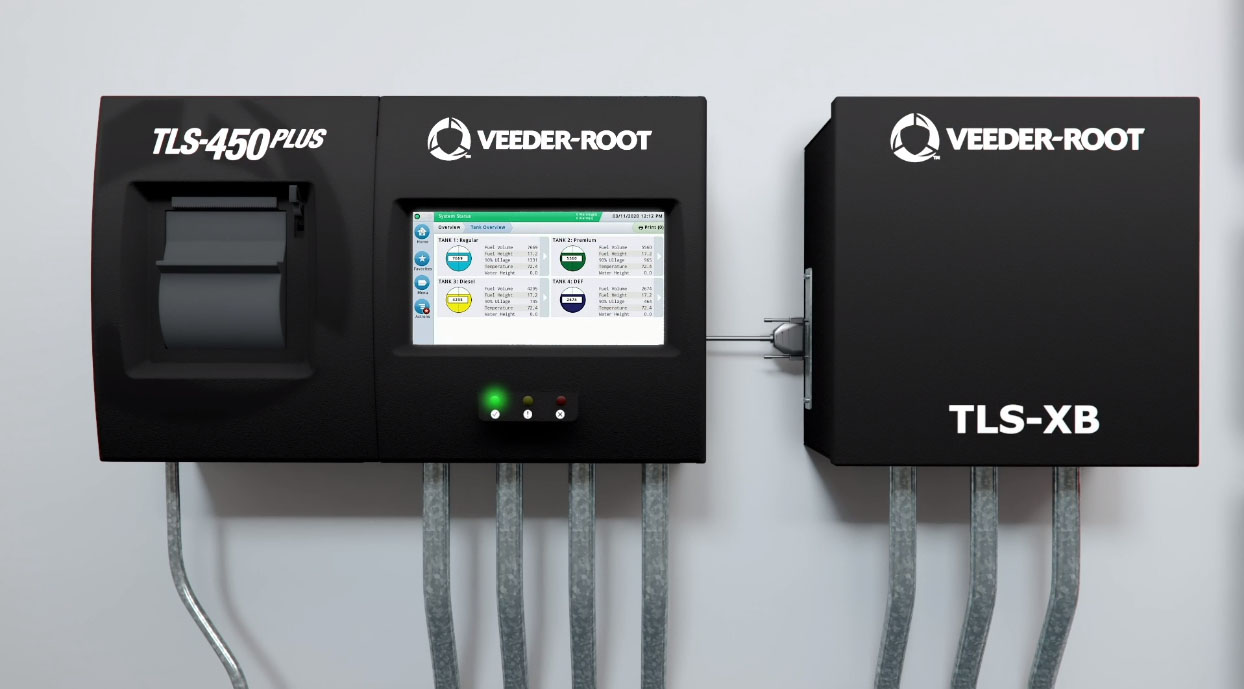

Automatic Tank Gauge Requirements

- TLS-450PLUS Automatic Tank Gauge (ATG) or TLS4 ATG with TLS-XB Expansion Box and software version 10.H or higher to support all HydrX functionality.

- HydrX requires a Universal Sensor Module (USM) with 2 unused inputs and a Universal Input/Output Module (UIOM) with 3 unused relay outputs and 1 unused high-voltage input. If the ATG has the required spare inputs and outputs (I/O), no new modules will be required.

- HydrX is compatible with Mechanical Line Leak Detection (MLLD) and Digital Pressurized Line Leak Detection (DPLLD).

- If upgrading from a TLS-350 to a TLS-450PLUS ATG, Pressurized Line Leak Detection (PLLD) will have to be upgraded to Digital Pressurized Line Leak Detection (DPLLD).

Submersible Turbine Pump Requirements

- Compatible with 4″ STPs up to 4 HP and Red Jacket® Maxxum® 6" STPs up to 5 HP.

- Veeder-Root Compatible STP Models: The Red Jacket®, The Red Jacket AG, The Red Armor®, and The Red Jacket Maxxum®.

- FE Petro® Compatible STP Models: MagShell™ fixed speed and variable speed STP with MagVFC™.

- Line manifolded and siphon manifolded tanks with STPs are supported. Siphon manifolded tanks without STPs are not supported.

- STP must have a spare pressure port available.

Note: Sump sensors are recommended with HydrX and may be required by local jurisdictions having authority.

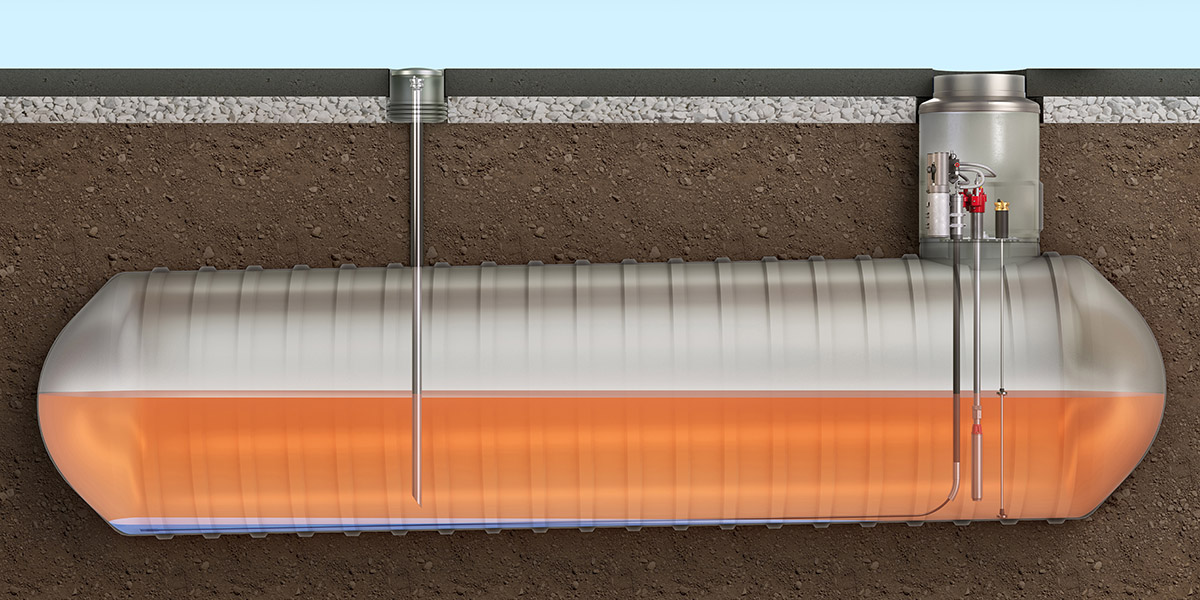

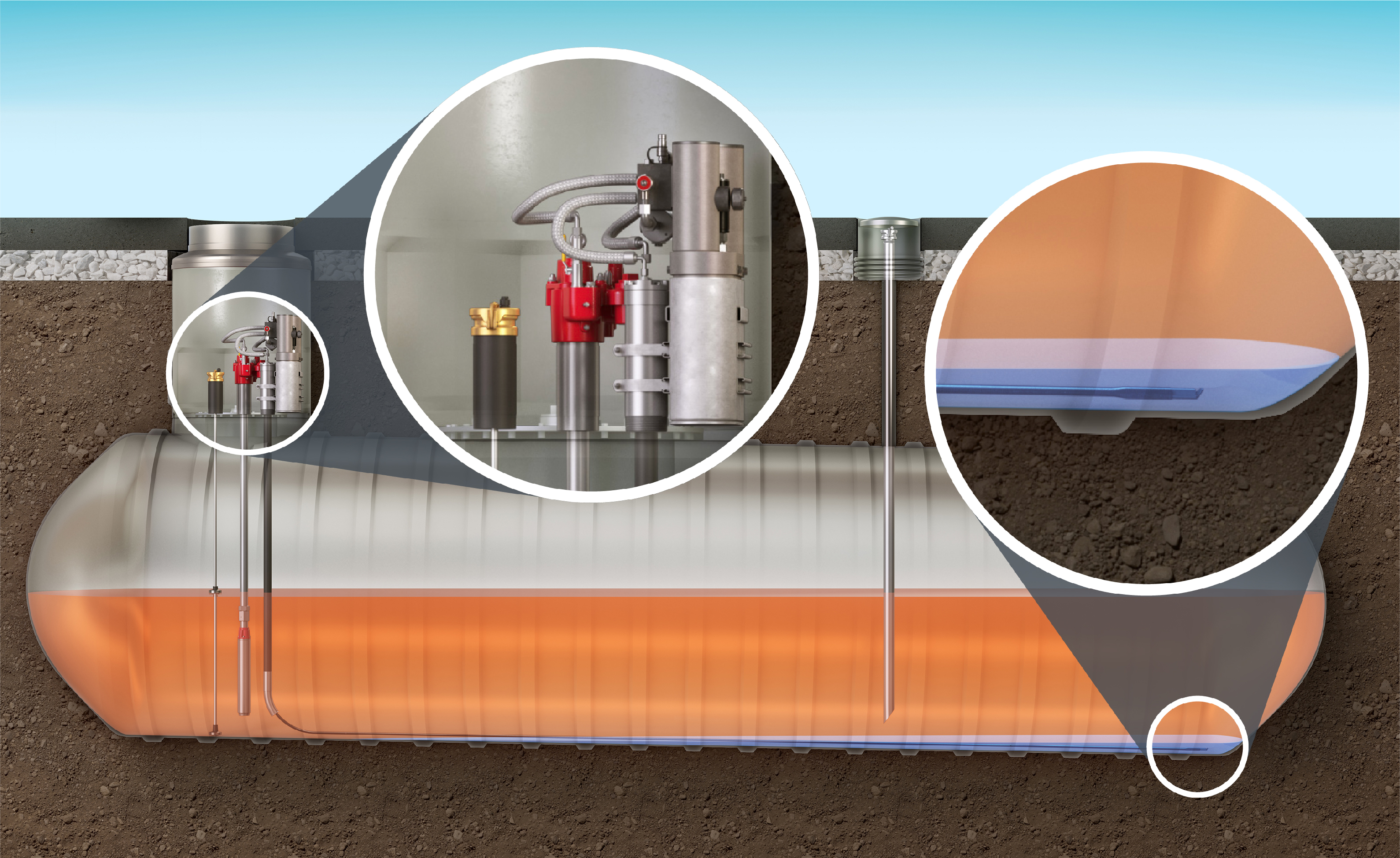

Tank Requirements

- HydrX is compatible with a range of underground and aboveground storage tanks fabricated out of fiberglass and steel.

General Tank Requirements:

- Diesel Storage Tanks less than or equal to 30,000 gallons.

- Tank diameter must be between 4' (48") and 12' (144").

- Fiberglass and steel tanks are supported.

- Line manifolded and siphon manifolded tanks with STPs are supported. Siphon manifolded tanks without STPs are not supported.

Steel Tank Requirements:

- Ensure there are no obstructions for the Water Intake Device (WID) to slide past the monitoring fitting extending into the tank space. If the monitoring fitting is in the path of the WID, HydrX should be installed in a 4" fitting that is offset from the tank centerline so the WID passes by the monitoring fitting without obstruction.

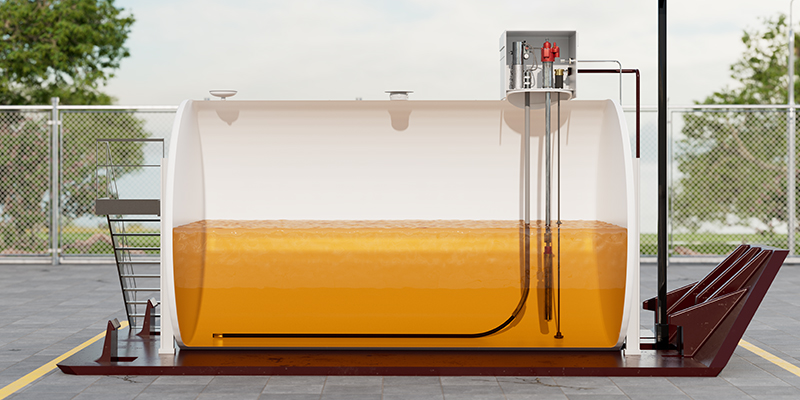

Aboveground Tank Requirements:

- Mount the Fuel Conditioner on top of the tank.

- Install the Fuel Conditioner inside an enclosure with environmental controls to ensure operating temperatures are met.

- A containment monitoring device must be used inside the enclosure.

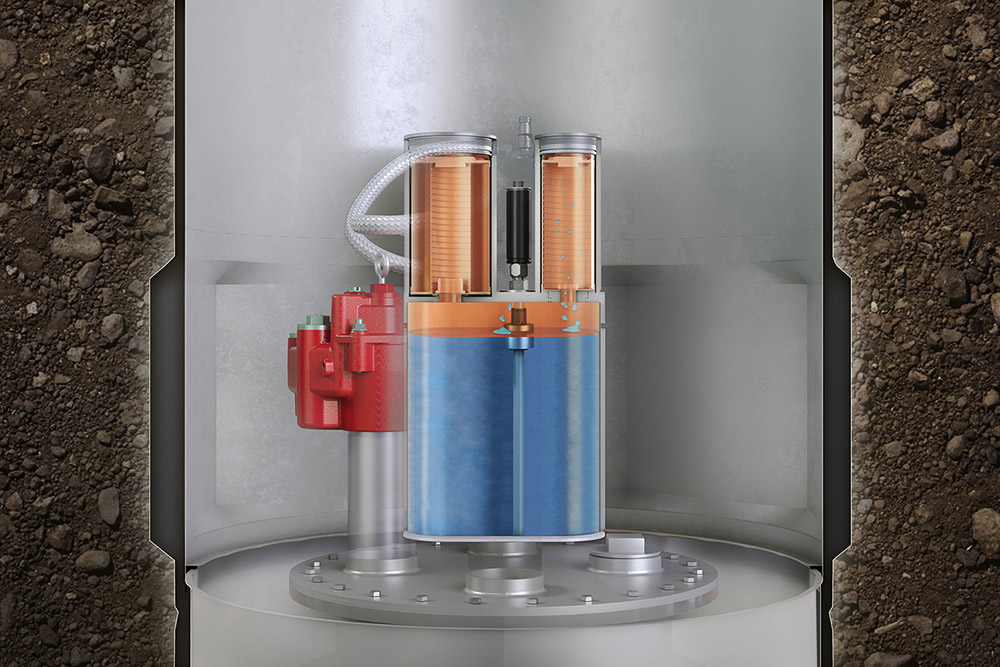

Sump Requirements

- A sump diameter greater than or equal to 42″ generally will have enough clearance. If smaller than 42″, a fit test is required.

- The Fuel Conditioner comes in two models: HydrX 250D with a 2.5-gallon waste water capacity that is 23" tall and HydrX 500D with a 5.0-gallon waste water capacity that is 30" tall. It requires 10" of clearance above the system to any fixed, immovable portion of the sump to service the filters. If the Fuel Conditioner fits in the center of the sump, directly under the sump lid, a 6″ clearance to the sump lid is sufficient.

- Spare 4″ bung in tank top with clearance for a riser (and space for the Fuel Conditioner required).

HydrX System Configurator

Complete the HydrX Fuel Conditioning System Site Inspection Guide (576047-355) to obtain the necessary information to input into the configurator and pinpoint the part numbers required for your HydrX Fuel Conditioning System.

Get StartedFE Petro® is a registered trademark of Franklin Electric Company, Inc.

MagShell™ and MagVFC™ are trademarks of Franklin Electric Company, Inc.