Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

Introduction

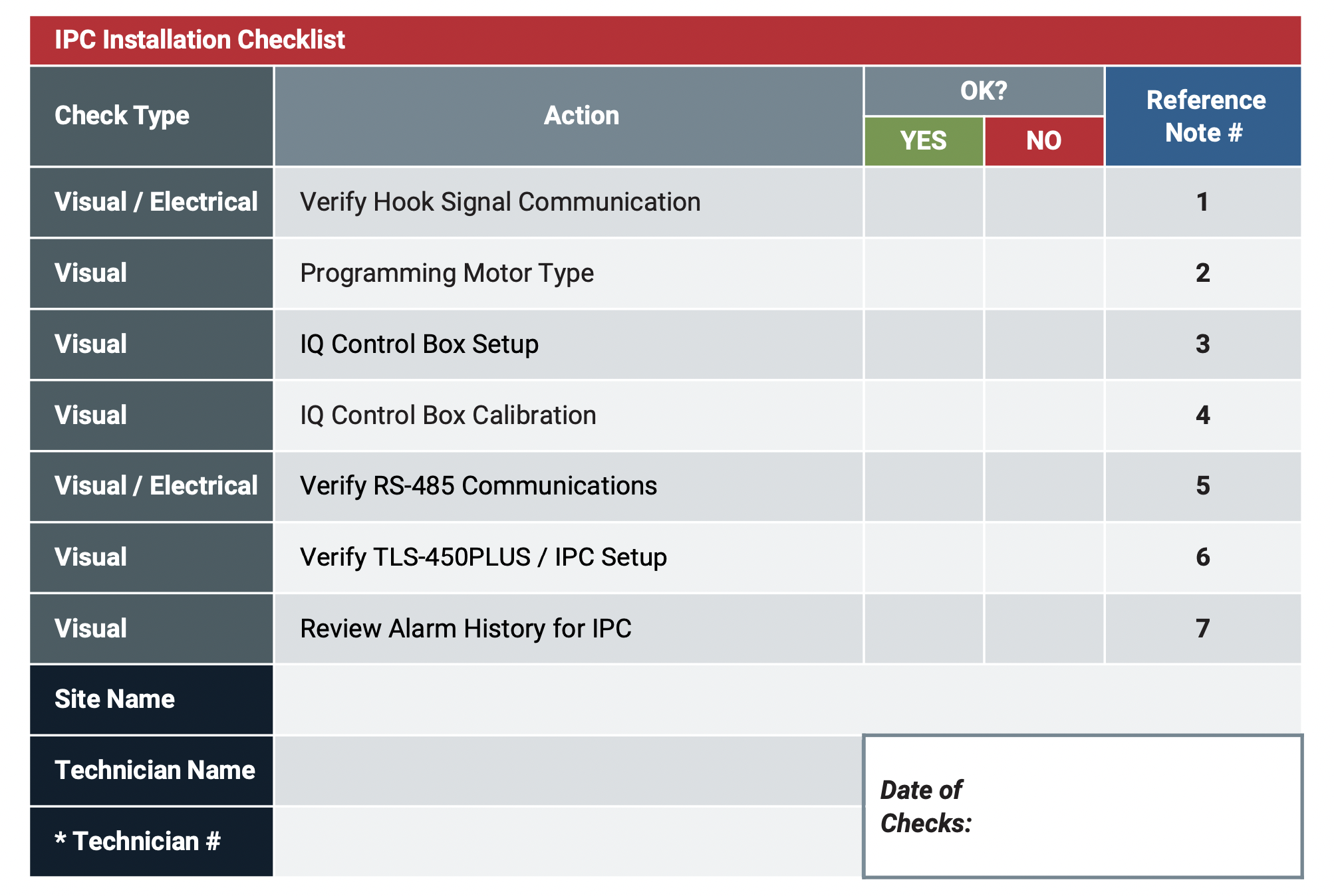

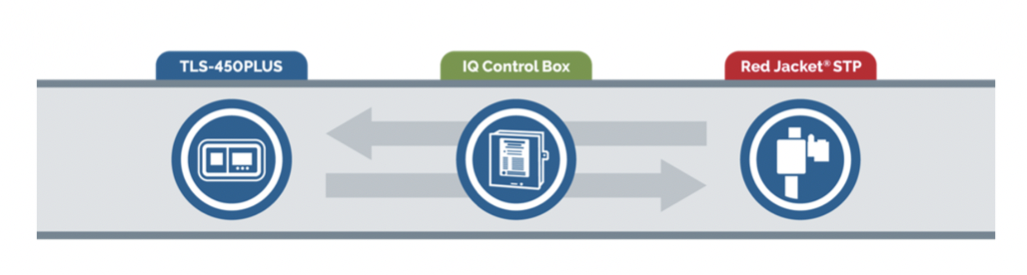

This checklist is specific to Intelligent Pump Control (IPC) with Red Jacket IQ Control Boxes. It will provide Technicians and Owners with the documentation that IPC has been installed correctly.

* Your Technician # can be found on your Red Jacket Foundation Certificate.

Note: This checklist should be used in conjunction with the IQ Control Box Installation and Owner’s Manual (051-330).

Guidance Notes for Red Jacket IPC Installation CheckNote 1 – VERIFY HOOK SIGNAL COMMUNICATION

|

|

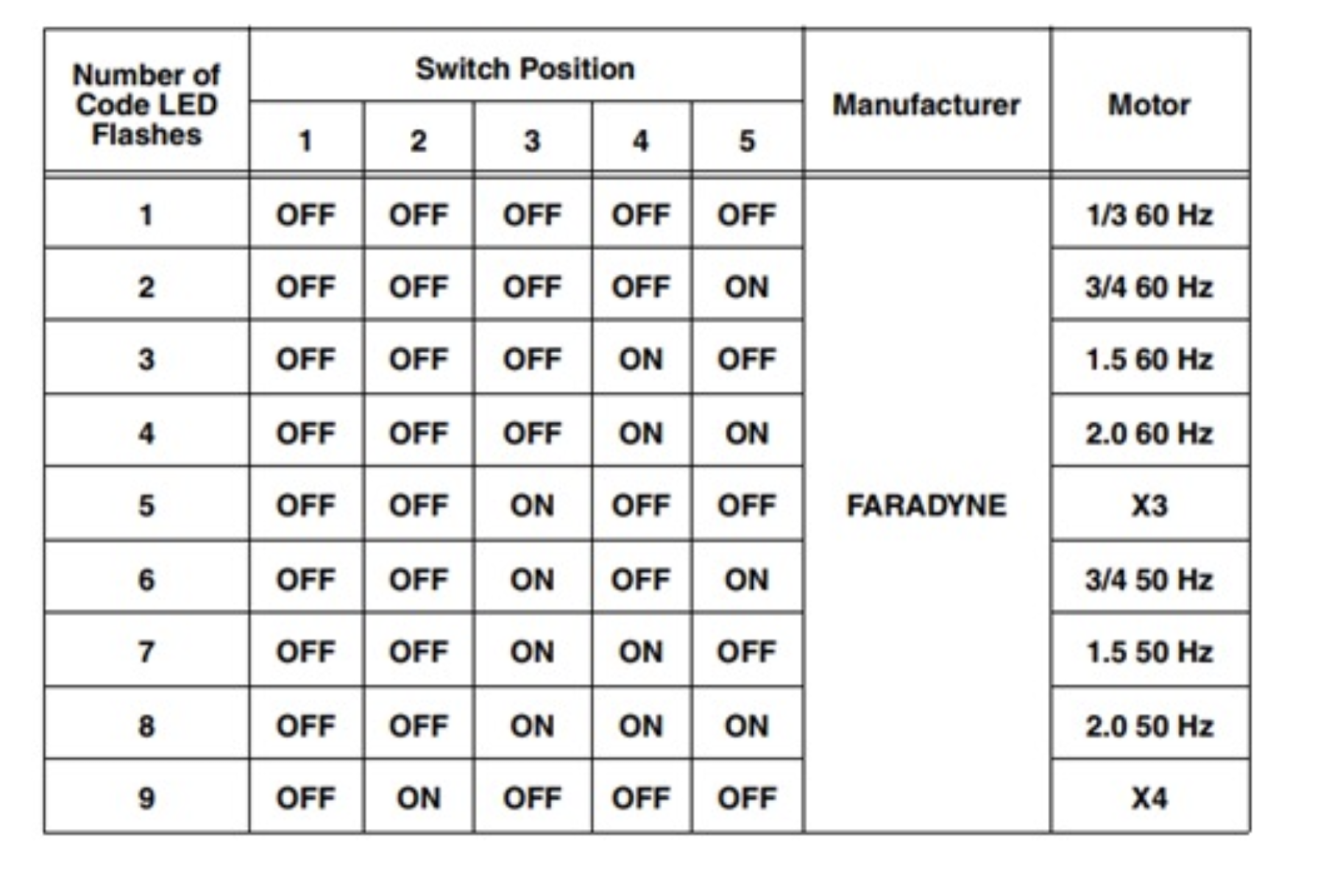

Note 2 – PROGRAMMING MOTOR TYPE

|

|

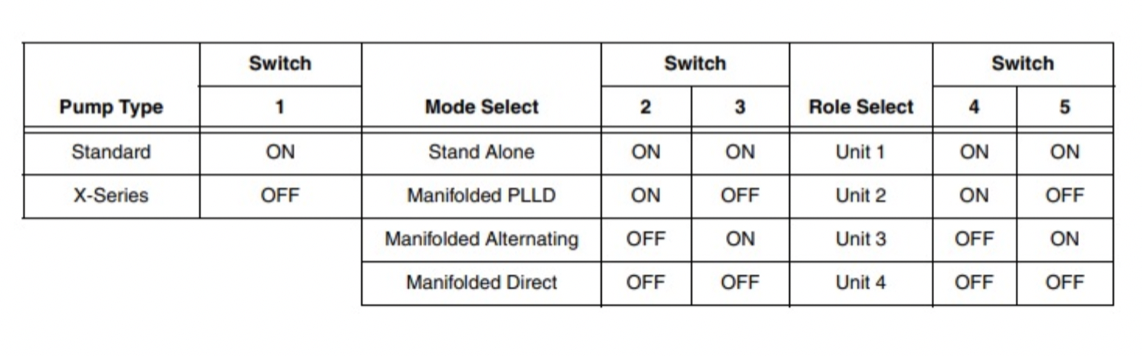

Note 3 – IQ CONTROL BOX SETUP

|

|

Note 4 – IQ CONTROL BOX CALIBRATION

|

|

Note 5 – RS-485 COMMUNICATIONSa. Verify Wiring from IQ Control Box to TLS-450PLUS is in accordance with: Manual 051-330 b. Verify RS-485 Com Module is installed in compatible slots in accordance with: Manual 051-330 |

|

Note 6 – VERIFY TLS-450PLUS / IPC SETUPa. Verify Communications are programmed. b. Manual 051-330, Appendix A. c. Verify proper addressing of pumps in setup on TLS-450PLUS. d. Verify Dispenser Mode is active and programmed. e. Auto Event Generation (verifying Switch-on-the-Fly). f. With a handle signal active, turn off (remove power) from the Primary Pump at the breaker and ensure the Secondary Pump comes on. |

Note 7 – REVIEW ALARM HISTORY FOR IPCa. Review if IPC Alarm(s) occur. b. After High Throughput Activity, verify helper condition was activated, use serial command to verify. |

|

Manual Reference NotesIQ Control Box Installation and Owner's Manual, 051-330 Rev. K https://docs.veeder.com/gold/download.cfm?doc_id=9974

The Red Jacket STP Installation, Service, & Parts Lists Manual, 577013-830 Rev. AC |

Further InformationContact Veeder-Root Technical Support at +1.800.323.1799 for additional help or questions. |