Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

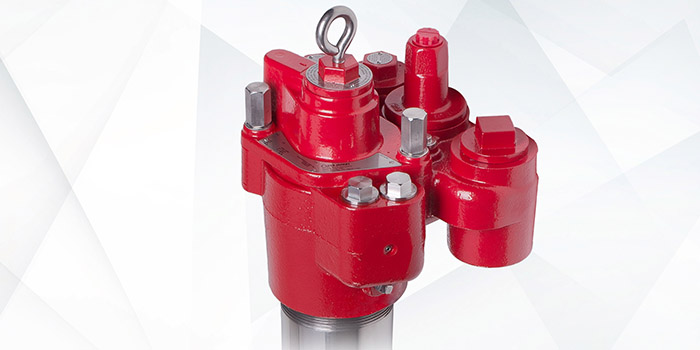

Veeder-Root has released the new Red Jacket Red Armor Submersible Turbine Pump to withstand in-sump corrosive environments and avoid the deterioration of pumping equipment.

Microbial activity that produces and exposes the submersible turbine pumps to acetic acids on wet and dry surfaces can lead to accelerated pitting and deterioration over time. In-sump corrosion can be minimized by preventing ethanol fuel or vapors, and water, from entering the sump by following best practices regarding maintaining STP and sump fittings (1*). In many cases high water tables, ambient moisture, or condensation, prevent operators from maintaining dry sumps. In these cases where maintaining a dry sump is difficult, the Red Jacket Red Armor STP provides a solution to avoid corrosion on the STP.

The Red Armor STP has a specialty coating on the manifold and discharge head that withstands acetic acid exposure to prevent deterioration and pitting to the cast iron surface over time. The Red Armor packer manifold also contains stainless-steel hardware to ensure ease of maintenance throughout the life of the pump. To combat corrosion in-tank, the Red Armor STP features stainless-steel column piping and quick-set connector.

This series of pumps is built upon the same field proven Red Jacket STP platform with identical sizes as the long standing "The Red Jacket" and the "The Red Jacket AG" models. The specialty coating selected for the Red Armor series was the toughest performing coating during ASTM acetic acid spray testing. Additionally, the coating stood up to a battery of abrasion, immersion and impact tests.

In-sump protection includes powder coated packer manifold, stainless steel riser, nuts, springs, screws, check valve seat, eye bolt, and check valve guide

In-tank protection for the pump includes powder-coated discharge head, stainless column pipe and quick-set connector.

Fuel Compatibility:

• 100% Gasoline

• 100% Diesel

• 0-100% Biodiesel blends

• Jet fuel

• AVGAS

• Kerosene and Fuel Oil

• Methanol concentrations up to 100%

• Ethanol concentrations up to 90%

• MTBE, ETBE, or TAME concentrations up to 20

4 Motor Sizes Available:

• ¾ HP, 60 Hz, 1 – phase

• 1 ½ HP, 60 Hz, 1 – phase

• X3 1 ½ HP, 60 Hz, 1 – phase, high pressure

• 2 HP, 60 Hz, 1 – phase

Optional stainless steel trapper intake screen to block corroded tank debris from clogging dispenser filters (144-194-5)

*1. Wilson and Co-Authors. Corrosion in STP Sumps: What Causes It and What Can Be Done About It? 2013. PEI Journal. Volume 7, Issue 3, third quarter 2013, pages 26-34.