Monitor storage tanks that require flex probe solutions

Mag-FLEX is an ideal solution for fuel distribution depots, marine terminals, aviation fueling installations and many other facilities where fuels are stored in bulk. It utilizes the proven Veeder-Root magnetostrictive probe technology installed in over 500,000 tanks globally. This solution, paired with any Veeder-Root Automatic Tank Gauge (ATG), creates a powerful inventory management system backed by the support network and reliability of Veeder-Root. It delivers accurate reconciliation of your most expensive on-site assets while eliminating the safety hazard of scaling formidable heights to determine inventory levels of aboveground storage tanks (ASTs).

Key Features & Benefits

- Single point of monitoring: Automate product level, water level and temperature monitoring of storage tanks with a Veeder-Root fuel monitoring system.

- Water detection: Identify possible water intrusion and ensure fuel quality with a water float system. The standard water float included detects water at the 5.5” (14cm) level. An optional low-level water float is also available for water detection at the 1.9” (4.8cm) level, which requires 4” (10.2cm) tank opening.

- Wireless & Wired applications: Save installation time and cost with wireless technology, which eliminates wiring from the tank to the ATG. Where wireless is not practical, Mag-FLEX accommodates traditional wired installation as well.

- Scalable solution to various site profiles: The Veeder-Root ATG portfolio offers a wide range of consoles to best suit various site configurations.

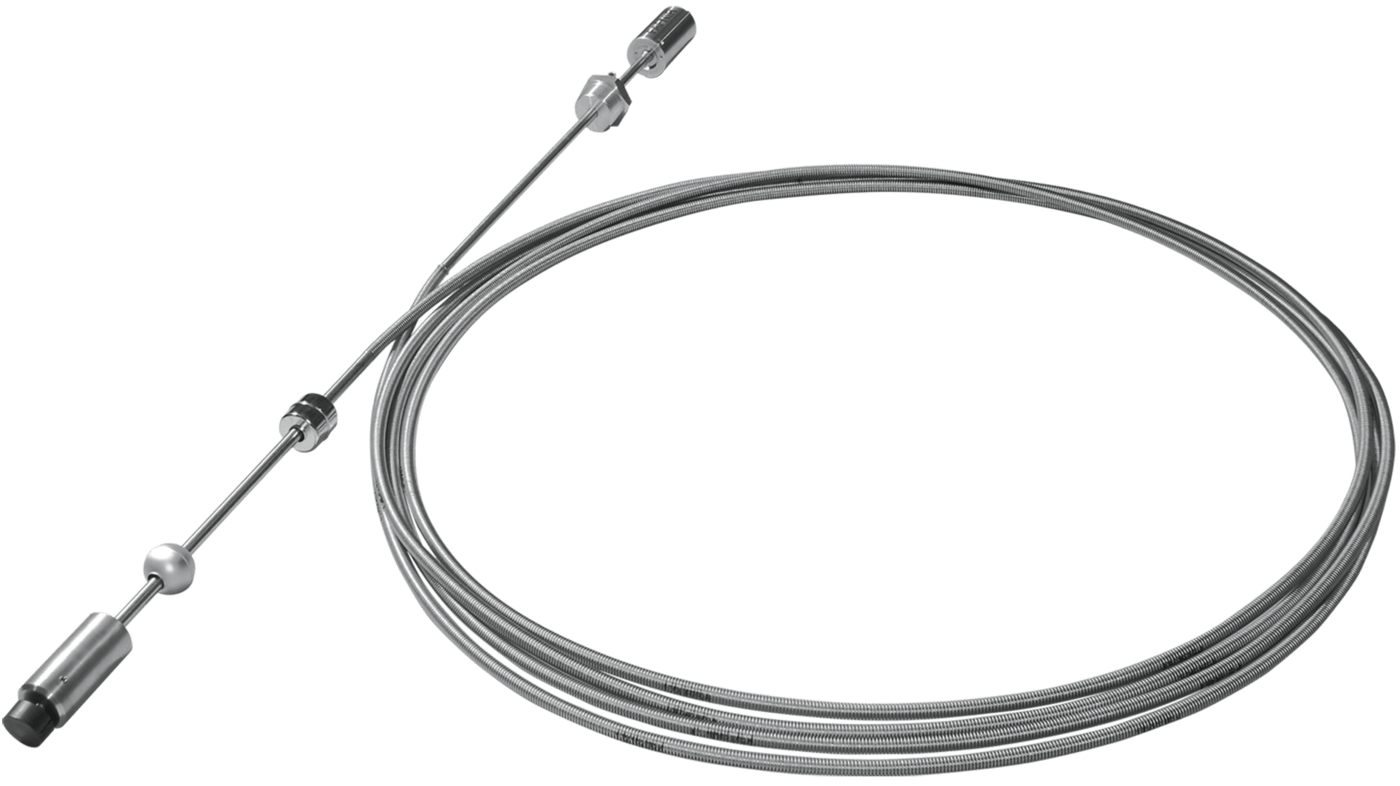

- Flexible, corrugated probe design: Provides easy transportation and installation.

- Stainless steel probe shaft: Provides increased protection of the mag wire and probe durability.

Product Form

| Part Number | Description | Console Type | Certification |

| 889591-4XX | Mag-FLEX Stainless Steel Probe with gasoline & water floats, wired | TLS-450PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-4XX | Mag-FLEX Stainless Steel Probe with gasoline & water floats, wired | TLS-450PLUS, TLS4, and TLS4B | ATEX |

| 889591-5XX | Mag-FLEX Stainless Steel Probe with diesel & water floats, wired | TLS-450PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-5XX | Mag-FLEX Stainless Steel Probe with diesel & water floats, wired | TLS-450PLUS, TLS4, and TLS4B | ATEX |

| 889591-6XX | Mag-FLEX Stainless Steel Probe with no water float, wired | TLS-450PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-6XX | Mag-FLEX Stainless Steel Probe with no water float, wired | TLS-450PLUS, TLS4, and TLS4B | ATEX |

| 889591-8XX | Mag-FLEX Stainless Steel Probe for Methanol Tanks with no water float, wired | TLS-450PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-8XX | Mag-FLEX Stainless Steel Probe for Methanol Tanks with no water float, wired | TLS-450PLUS, TLS4, and TLS4B | ATEX |

| 889591-1XX | Mag-FLEX Stainless Steel Probe with gasoline & water floats, wired | TLS-450PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-1XX | Mag-FLEX Stainless Steel Probe with gasoline & water floats, wireless | TLS-450PLUS, TLS4, and TLS4B | ATEX |

| 889591-2XX | Mag-FLEX Stainless Steel Probe with diesel & water floats, wireless | TLS-450PLUS,TLS4, and TLS4B | UL/cUL |

| 889561-2XX | Mag-FLEX Stainless Steel Probe with diesel & water floats, wireless | TLS-450PLUS, TLS4, and TLS4B | ATEX |

| 889591-3XX | Mag-FLEX Stainless Steel Probe with no water float, wireless | TLS-450 PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-3XX | Mag-FLEX Stainless Steel Probe with no water float, wireless | TLS-450 PLUS, TLS4, and TLS4B | ATEX |

| 889591-7XX | Mag-FLEX Stainless Steel Probe for Methanol Tanks with no water float, wireless | TLS-450PLUS, TLS4, and TLS4B | UL/cUL |

| 889561-7XX | Mag-FLEX Stainless Steel Probe for Methanol Tanks with no water float, wireless | TLS-450PLUS, TLS4, and TLS4B | ATEX |

Flexible and Easy Installation

The flexible design of the Mag-FLEX probe allows it to be coiled, ensuring it can be packed compactly for low cost shipping and conveniently transported to the tank top, quickly ready for easy installation.

After the Mag-FLEX probe has been installed, the corrugated steel shaft is oriented vertically and held in its operating position by the integral weight and magnet. The probe floats will precisely follow the level changes in the tank and report the presence of any water. The Mag-FLEX probe utilizes magnetostrictive measuring technology to provide consistently accurate and repeatable data.

Specifications

Product Measurement

| Height accuracy | ±0.08" (±0.2cm) |

| Repeatability | ±0.02″ (±0.05cm) |

| Minimum product level reading | 7.3″ (18.5cm) |

| Float size | 1.7″ (4.3cm) |

Water Measurement

| Standard | Optional | |

| Height accuracy | ±0.12″ (±0.3cm) | ±0.12″ (0.3cm) |

| Repeatability | ±0.02″ (±0.05cm) | ±0.02″ (±0.05cm) |

| Minimum water level reading | 5.5" (14cm) | 1.9" (4.8cm) |

| Float size | 1.7" (4.3cm) | 4" (10.2cm) |

Temperature Measurement

| Operating range | -40°F to 140°F (-40°C to 60°C) |

| Accuracy | ±0.36°F (±0.2°C) @ -40°F (-40°C) to 185°F (85°C) ±0.18°F (±0.1°C) @ -4°F (-20°C) to 131°F (55°C) |

| Repeatability | ±0.5°F (±0.5°C) |

| Resolution | 0.1°F (0.1°C) |

| Thermistors | 5 Thermistors |

Installation Details

| Probe shaft length | Up to 72’ (22m) tank height |

| Tank adapter/tank entry | R 1.5" (3.8cm) screw-in unit |

| Height adjustment range | ±9.8" (24.9cm) |

| Electrical connection | M12 plug-in connection |

| Protection class | IP68 |

Sensor Materials

| Probe canister | Stainless steel 303 |

| Rigid shaft sections | Stainless steel 304 |

| Corrugated flexible shaft and floats | Stainless steel 316 Ti |

| Weight | Stainless steel 303 |

| Magnet casing | Conductive plastic |

General Information

| Options | Tank adapter made of stainless steel. Weight made of stainless steel. |

| Certifications | ATEX, IECEx, UL, cUL |

Documents

- Mag-FLEX In-Tank Probes for Monitoring Gas, Diesel, & Alternative Fluids (577014-449-07)

- Mag-FLEX Tall Tank Monitoring System Brochure (576047-196)

- Mag-FLEX Probe Installation Manual (577014-042)

- Mag-FLEX Probe Low Level Water Float Kit (577014-056)

- Veeder-Root Commercial & Industrial Product Guide (576047-533)