Overview

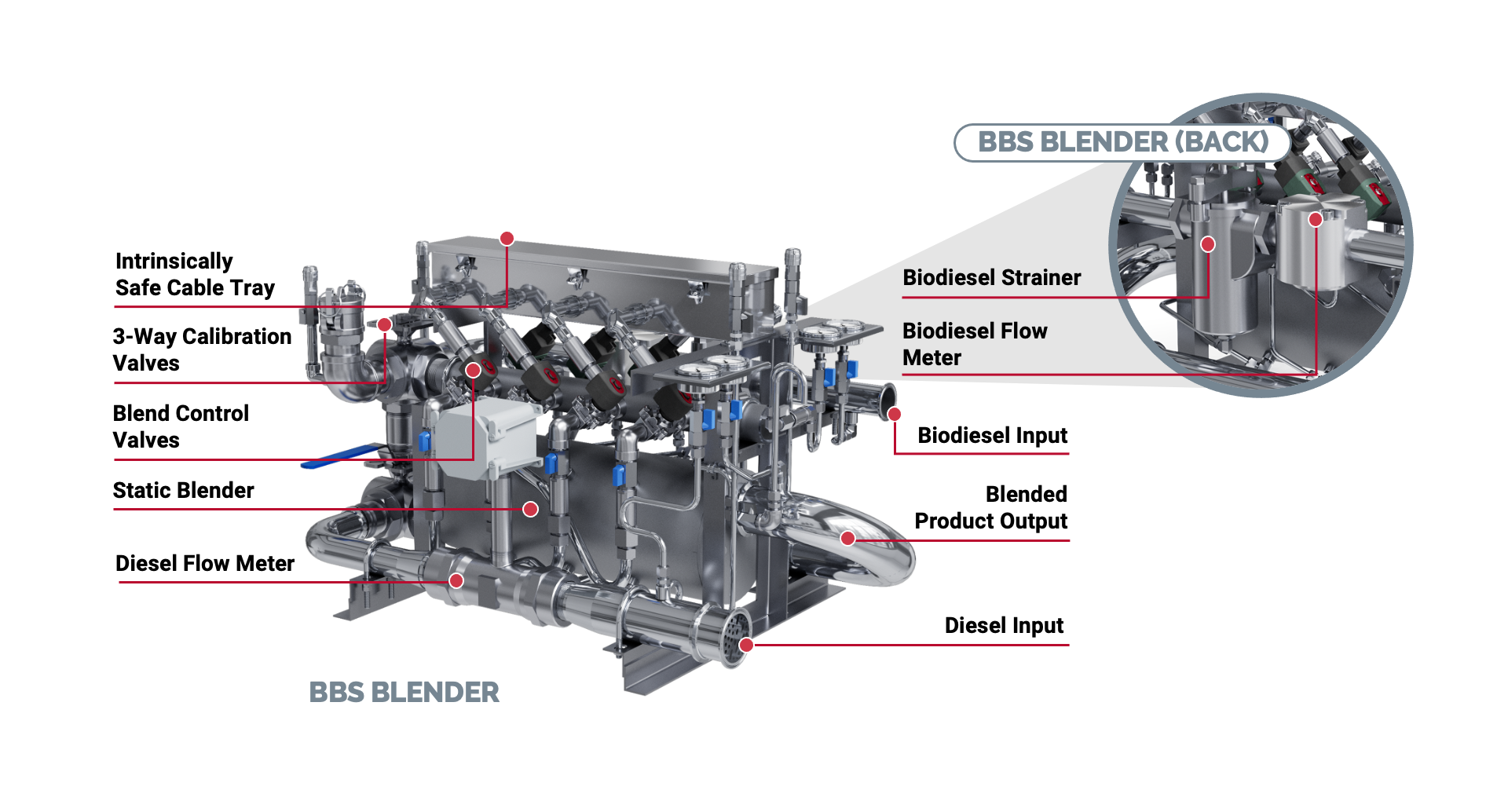

The Biofuel Blending System (BBS) is an in-line blending system for biofuels. The BBS allows the end user to blend biofuels on the fly and closely manage blend ratios as the supply of feedstock fluctuates. It leverages the field-proven architecture of the Additive Injection System and positions retailers to capitalize on incentives being offered through the Renewable Fuels Standard Program as well as other state programs.

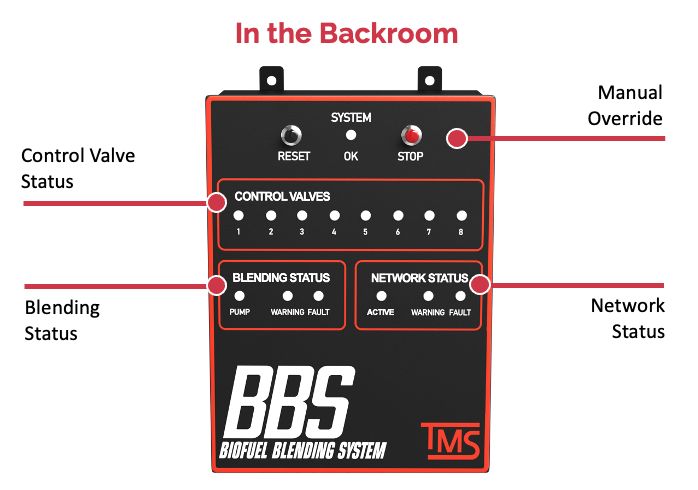

BBS Controller Features

-

Reset Button to reset/restart BBS blending operations

-

System OK Light indicates that BBS is working as intended

-

Stop Button to stop the blending operations

-

Solenoid Control Valve Lights 1-8 indicate which solenoid valve is currently injecting

-

Network Status Fault Light to indicate the BBS has lost connection with the ATG, and system is not currently blending

-

Network Status Warning Light to indicate intermittent problems with the network connection with the ATG

-

Blending Status Fault Light to indicate that a fault has occurred during blending operation and the system is not currently blending

-

Blending Status Warning Light to indicate that some error has occurred during blending operation

-

Pump Light to indicate that the BBS pump is running

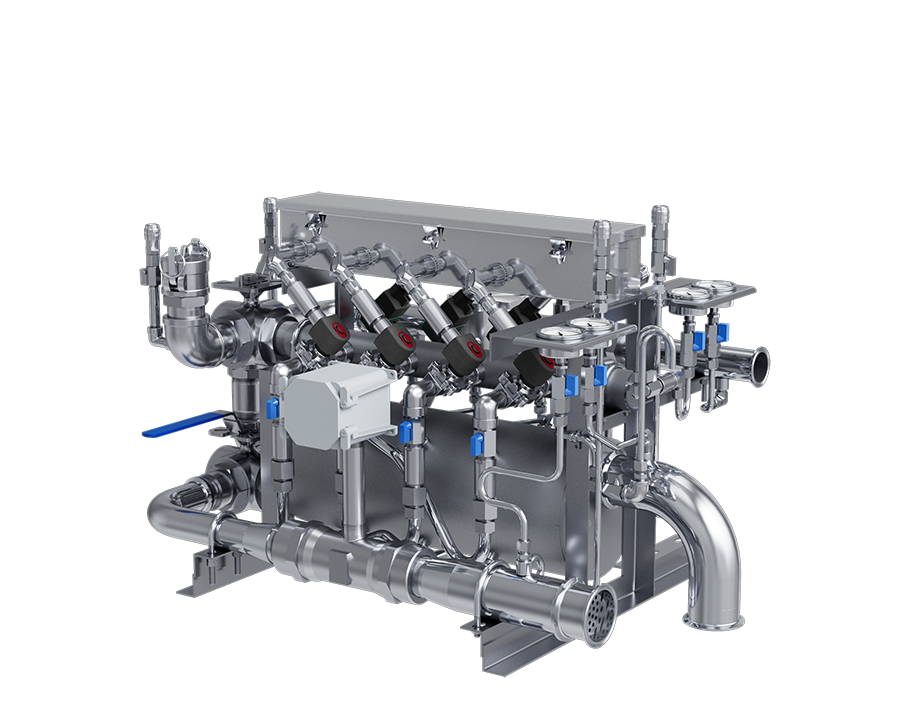

Aboveground System Options

The aboveground BBS is configured with the diesel and biodiesel product inputs and blended product output on the same side. This allows for the product lines to come into the same transition sump. Compatible sumps for this configuration are Fiberlite Gasboy 9840 and 9850 or equivalent. The aboveground BBS can be installed in a shed or small enclosure. The stainless steel enclosure (part number: 34001) is designed specifically for this configuration.

| Part Number | Description | Operating Parameters |

| 31801 |

BBS complete with controller and 2" in-line blending/injector. Product Input & Output connections are on the same side, suited for aboveground installations. |

5 - 180 GPM |

| 33501 |

BBS complete with controller and 3" in-line blending/injector. Product Input & Output connections are on the same side, suited for aboveground installations. |

30 - 350 GPM |

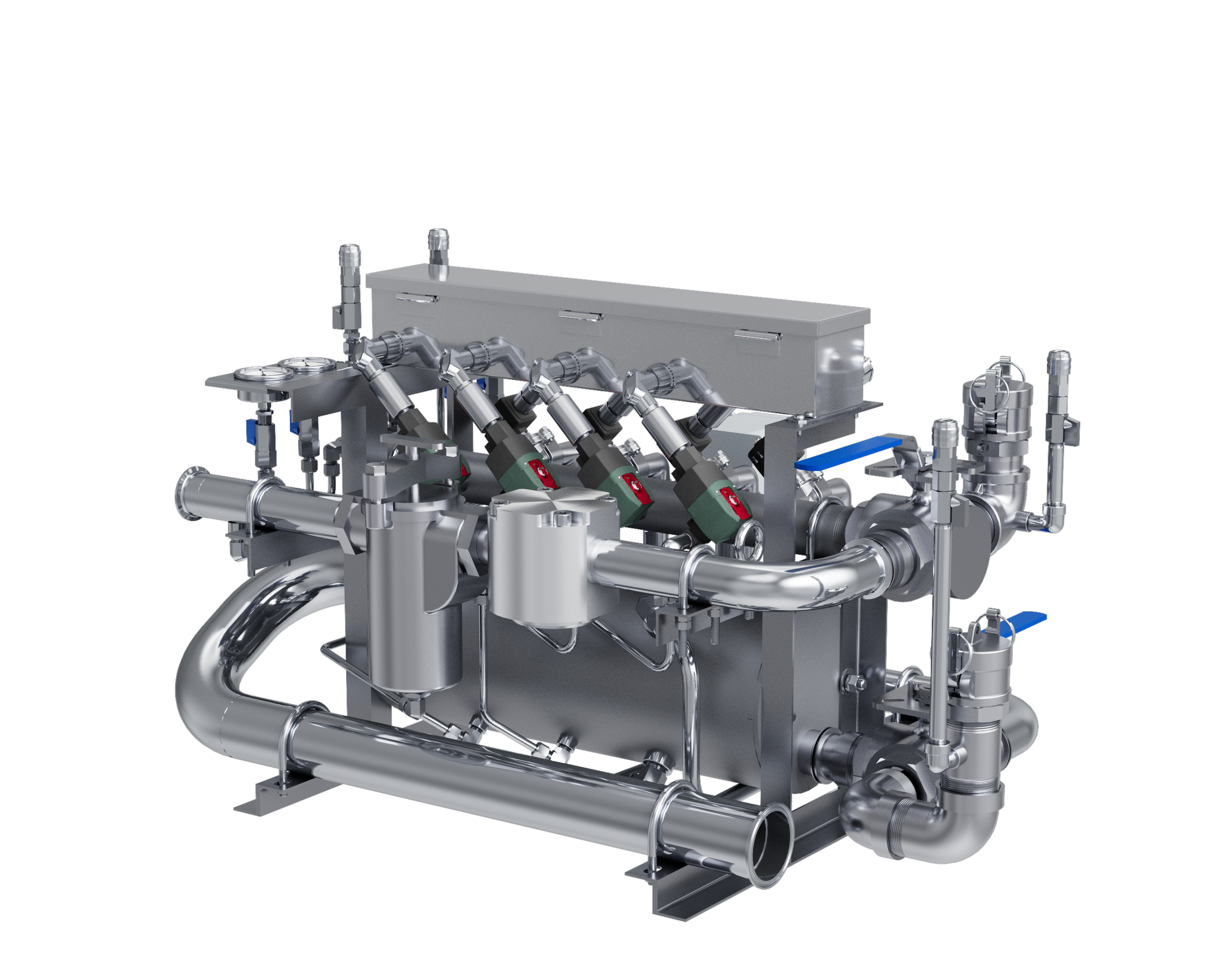

Underground System Options

The underground BBS is configured with the diesel and biodiesel product inputs and blended product output on opposite ends. This allows for the BBS to be installed in-line with the product lines and main trunk line going out to the dispenser island. The underground BBS is ideal to optimize site lines and eliminates the need for secondary outbuildings. Compatible sumps for the underground BBS are the Bravo 66” L x 66” W x 60” H sump or equivalent.

| Part Number | Description | Operating Parameters |

| 31802 |

BBS complete with controller and 2" in-line blending/injector. Product Input & Output connections are on different sides, suited for underground installations. |

5 - 180 GPM |

| 33502 |

BBS complete with controller and 3" in-line blending/injector. Product Input & Output connections are on different sides, suited for underground installations. |

30 - 350 GPM |

The Biofuel Blending System is in partnership with Total Meter Services Inc.

The Biofuel Blending System is in partnership with Total Meter Services Inc.