The Complete DEF Management Solution

As the demand for diesel-based Selective Catalytic Reduction vehicles continues to rise, it’s crucial for sites to optimize their diesel exhaust fluid (DEF) management systems. Veeder-Root’s portfolio of innovative solutions is specifically designed to meet the unique challenges associated with DEF, providing a complete solution for any retail or commercial site.

Stored correctly Diesel Exhaust Fluid should have a shelf life of about two years but often the integrity of DEF can be affected by exposure to direct sunlight or consistently high temperatures. Integrating your site with Veeder-Root’s all-inclusive DEF management system gives operators the power to fight back against erratic leaks, messy cleanups, and temperature induced product degradation, associated with other DEF handling systems.

INTEGRATED DEF MANAGEMENT SOLUTIONS

Superior Flow

A flexible DEF pump that can be tailored to maximize value, while controlling cost

Recirculation Monitoring

Enables management of DEF quality in the most extreme environmental conditions

Inventory Management

Protect probes and users from contact with diesel exhaust fluid

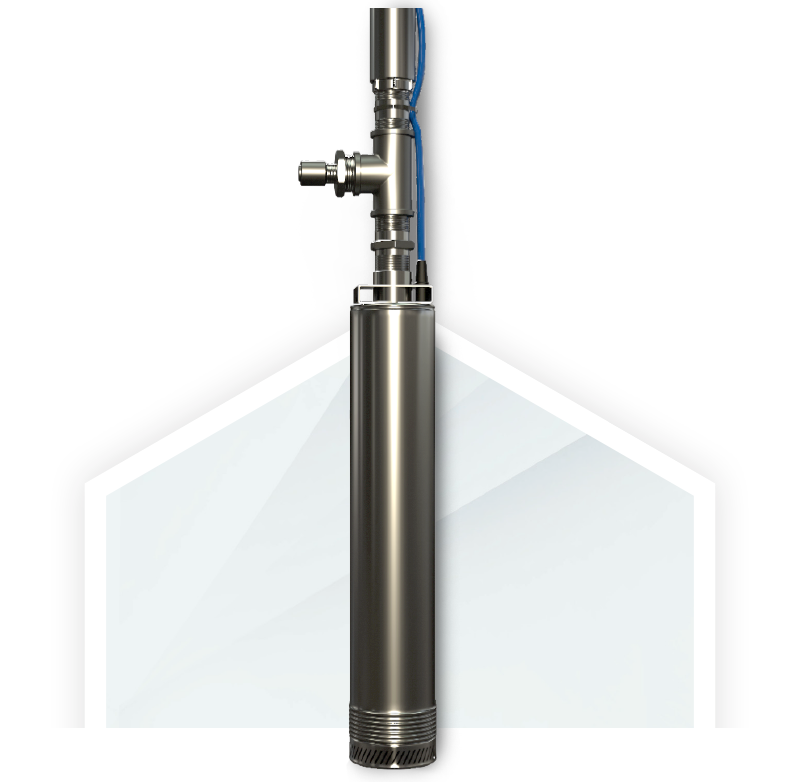

Red Jacket® CoreDEF Submersible Pump

The Red Jacket CoreDEF™ Submersible Turbine Pump (STP) sets a higher standard for any diesel exhaust fluid (DEF) pumping infrastructure. The CoreDEF™ STP is an entirely customizable DEF pump, designed to offer sites a complete solution to maximize value and minimize cost.

- ¾ HP and 2 HP options provide a range of light-to-heavy-duty power spanning all site applications

- Quick Set® variable lengths promote hassle-free application-specific height options

- The only DEF pump on the market offering adjustable pressure relief to further improve the customer experience

- Pre-assembly and factory leak testing included to ensure performance and reduce installation time to get you pumping sooner

Adjustable Pressure Relief Configuration

The Adjustable Pressure Relief Configuration is exclusive to the Red Jacket CoreDEF Pump and introduces post-installation flow adjustment to your diesel exhaust fluid system.

From within the sump, installers can now easily calibrate line pressure to optimize operation with even the most sensitive dispensing equipment.

TLS-450PLUS Automatic Tank Gauge with DEF Recirculation Feature

Unlike fueling products, diesel exhaust fluid is extremely temperature sensitive, and will freeze when exposed to temperatures below 12˚F or break down in conditions above 86˚F.

Veeder-Root’s DEF Recirculation Feature on the TLS-450PLUS tank gauge:

- Integrates DEF management into tank gauge so an entire site’s wetstock can be managed on one console

- Utilizes a sensor to measure the temperature of the DEF fluid between the tank and dispensing system

- Enables management of DEF quality in the most extreme environmental conditions

- Capable of controlling automated heat trace piping or in-tank heating coils

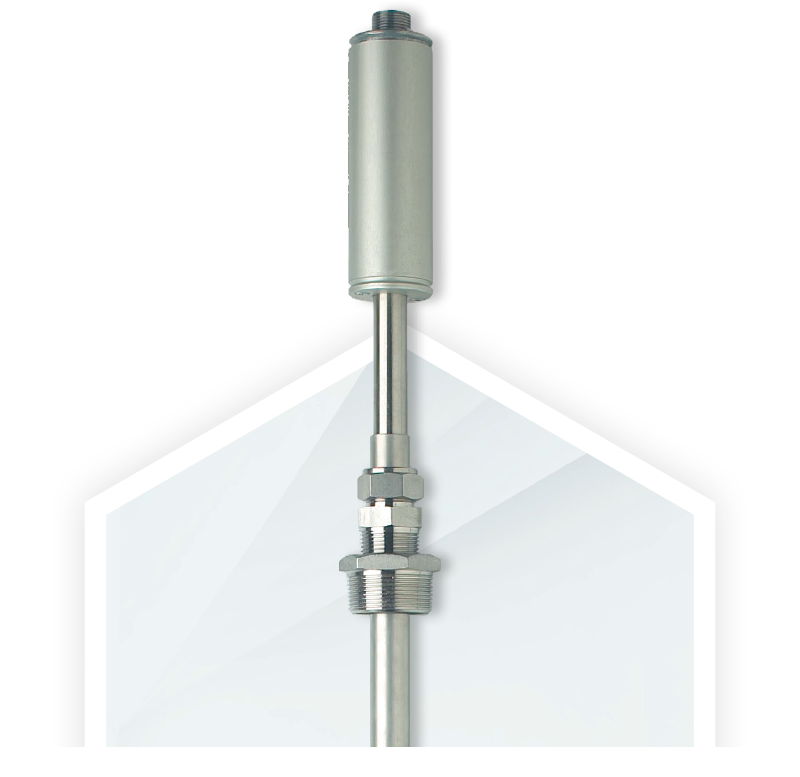

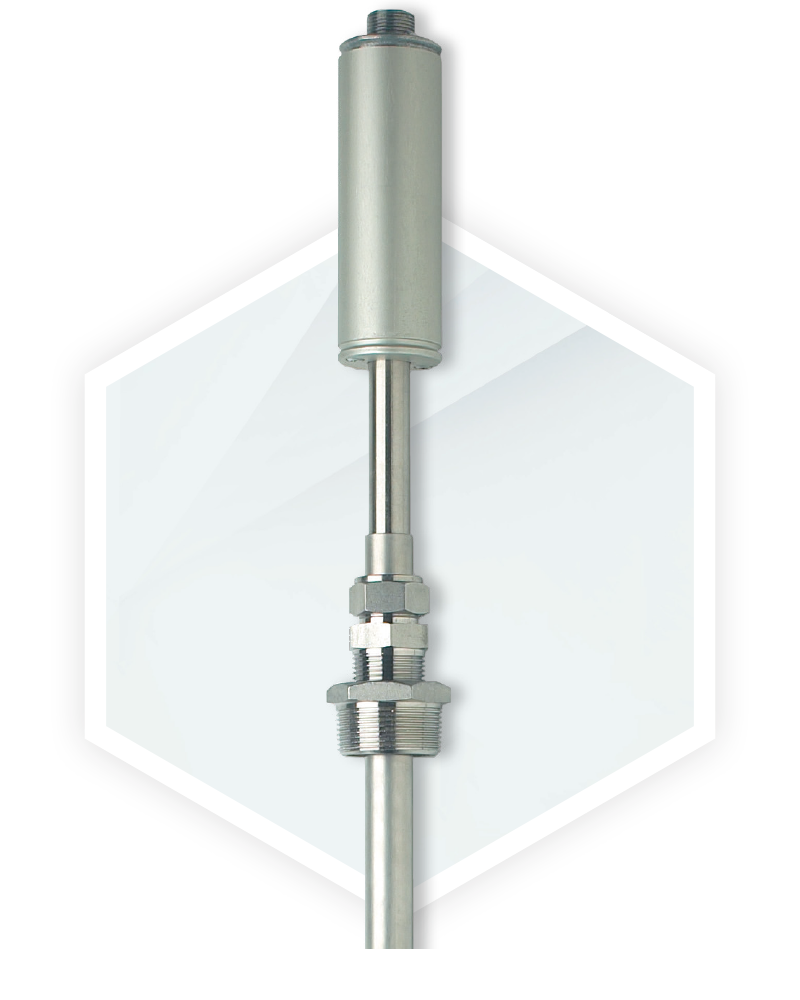

ISO-Chem Probe Kit for MAG-PLUS Probes

Veeder-Root’s multi-use Media-Isolated Probe (ISO-Probe) Kit allows diesel exhaust fluid tank owners and operators to accurately measure inventory levels using an automatic tank gauge.

- Armored with anti-corrosive, stainless steel tubing

- Highly-accurate magnetostrictive measurement technology

- Easy maintenance with isolated stainless steel jacket that protects probe and user from contact with diesel exhaust fluid

- Flawless inventory measurement, with five-point temperature sensing

- Promotes and enables optimal operation with TLS-450PLUS tank monitors

Streamline your DEF Management with integrated solutions

Maintaining viable diesel exhaust fluid relies on regulating its temperature throughout the dispensing system. Veeder-Root’s suite of products fully integrate together to help you manage your DEF fluid and maintain its quality.

The DEF Recirculation Feature on the TLS-450PLUS automatic tank gauge utilizes sensor and probe data to trigger the CoreDEF pump:

- A sensor in the dispenser pan notifies the TLS-450PLUS if the DEF product temperature in the line is too high or too low.

- The tank gauge activates the CoreDEF submersible turbine pump to begin recirculation and also enables supplemental line or tank heating systems if necessary.

- DEF product from the tank circulates through the lines, returning fluid from the line to the tank, regulating line temperature and ensuring DEF product quality.

- The sensor notifies the TLS-450PLUS when the temperature is acceptable, turning off the CoreDEF recirculation.