Directly Related

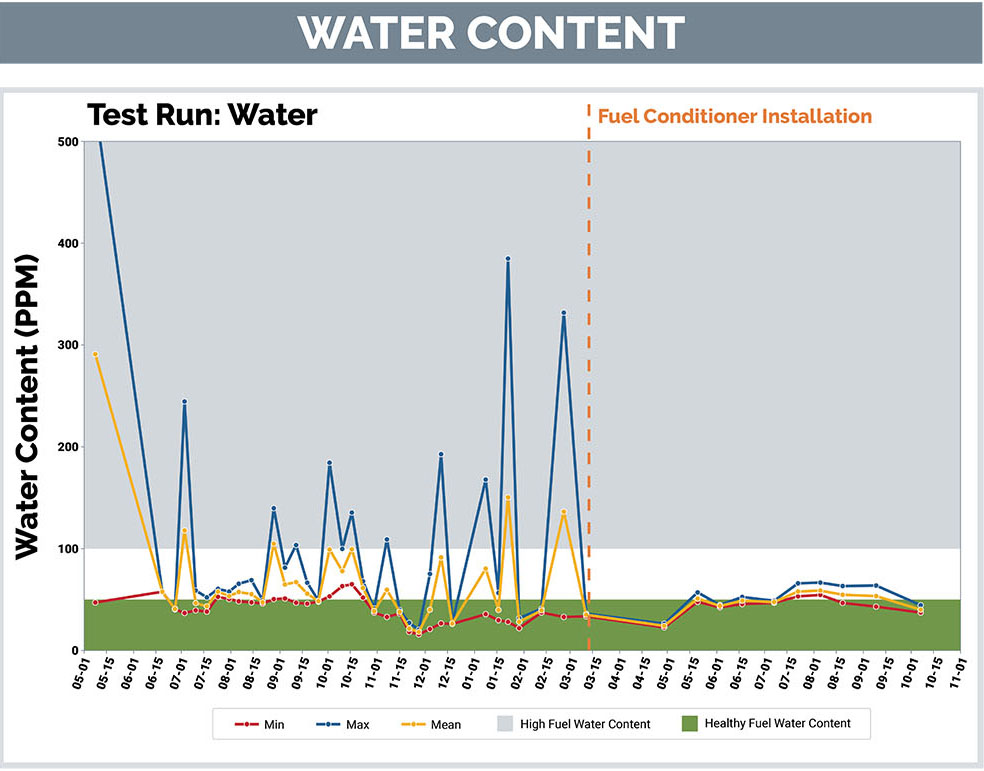

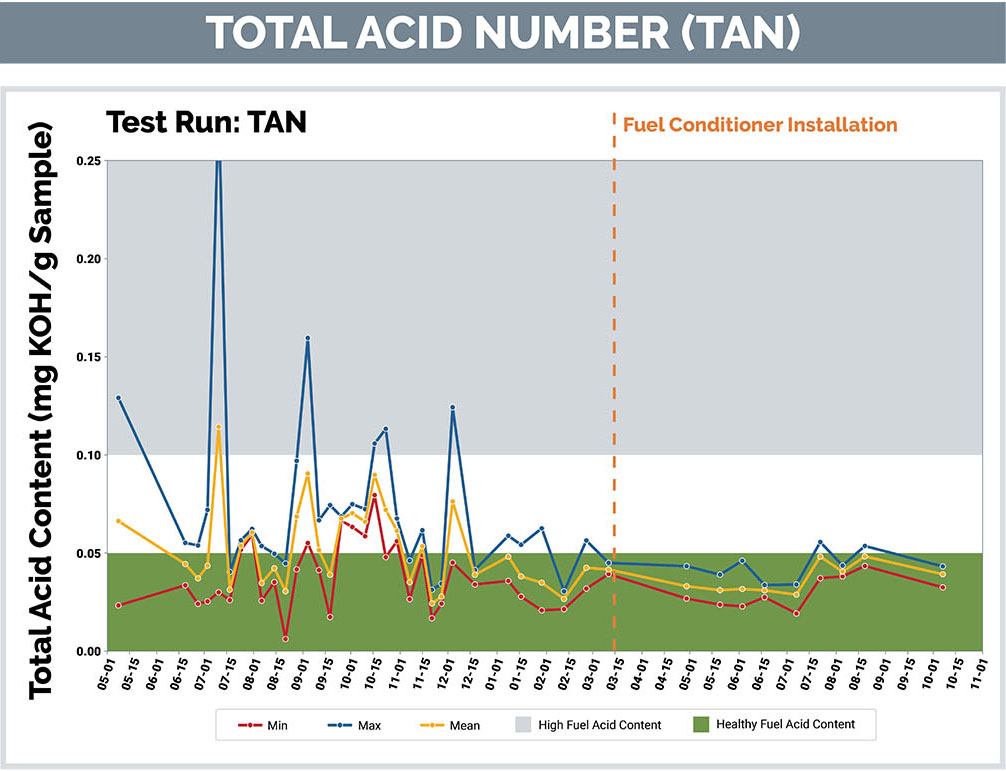

Additional research has shown just how strong the relationship is between water and fuel acidity. The higher the water level is, the higher the acidity levels in the tank are, and the more likely there is to be corrosion in the tank. Once the HydrX Fuel Conditioning System is installed and removes water from the tank, there is a quick drop-off in the acidity levels.

First Steps

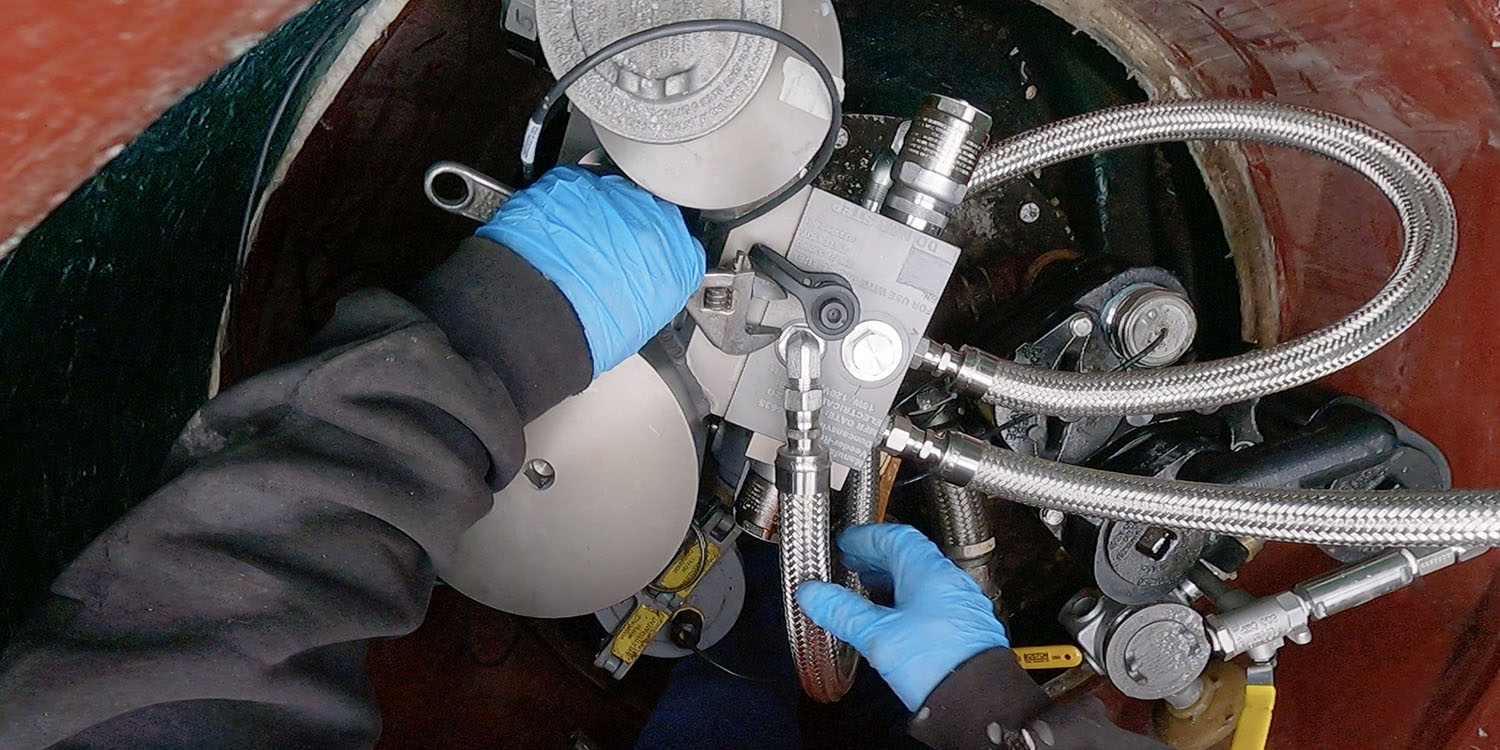

While installing a fuel conditioning system to filter out water is the best long-term solution, there are other steps you can take to reduce the amount of water in your tank.

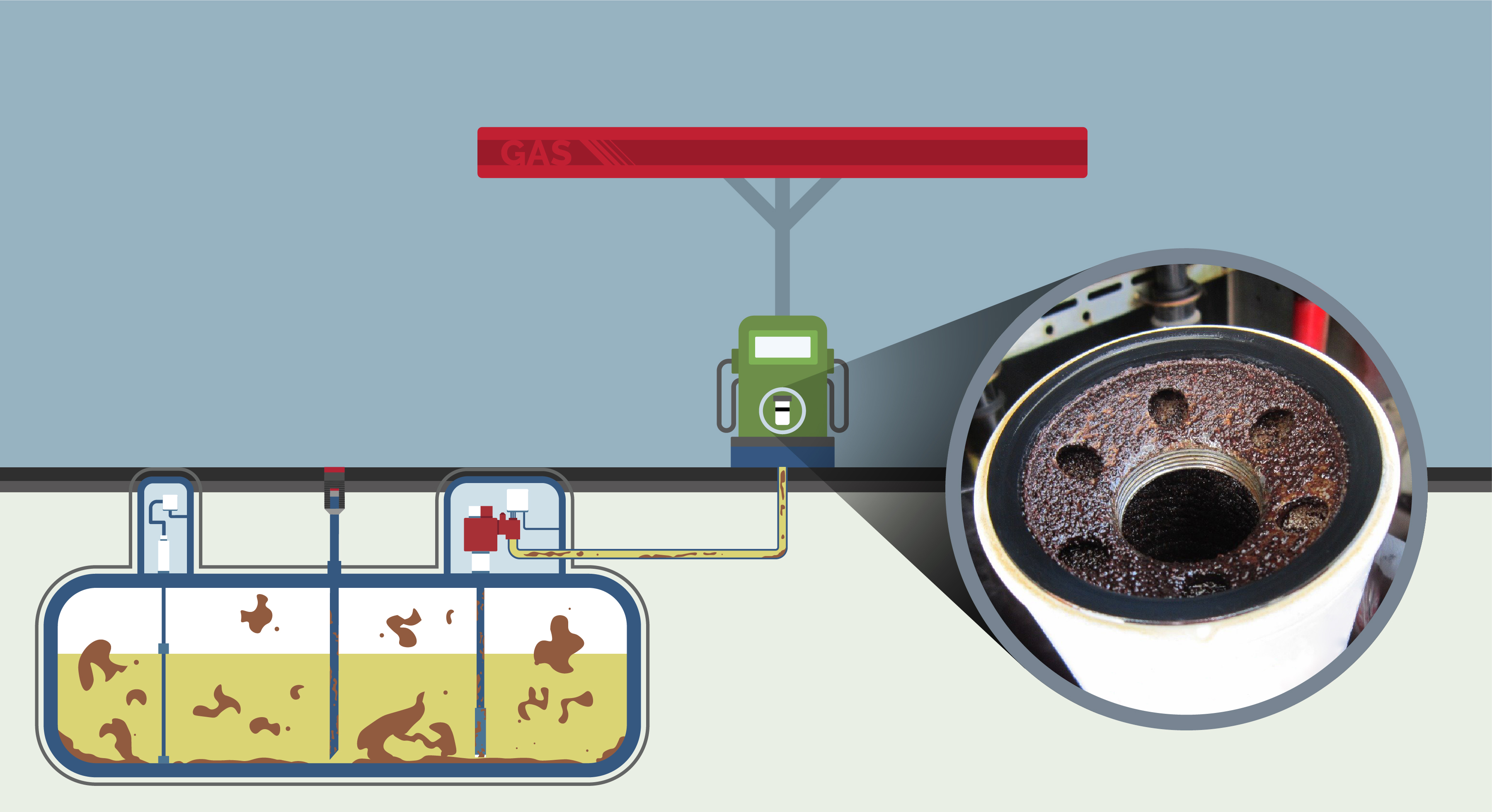

The first thing you should do is inspect your tank and fuel. Look for evidence of rust on any of the internal components like the inside of riser pipes or under-side of bungs. Check your fuel, look to see if samples from the bottom are coming out hazy or if there is sediment or standing water in the samples. Also, look for any leaky seals and assess whether the fueling system is holding pressure in the lines.

Where you can limit water from entering your fueling system - it is important to do so. This includes ensuring that all your fittings are watertight and repairing any leaking seals. This is especially important when the grade of your forecourt directs run-off water over the top of underground storage tanks. It is also important that spill buckets are regularly emptied to ensure that water does not enter the tank through loose caps or with deliveries when caps are removed.

Learn more about combating in-tank Corrosion

Read all our Combat Corrosion Articles

Water is integral to corrosive environments and a serious threat to diesel storage tanks and fuel equipment health. Learn more about the cause and impact of corrosion, and steps you can take to mitigate it.

Read More

* “Questions And Answers About Corrosion In Underground Tanks Storing Diesel Fuel.” U.S. Environmental Protection Agency, Office of Underground Storage Tanks, July 2016.