WHAT DOES THE EPA REQUIRE FOR TANK LEAK DETECTION FOR PETROLEUM?

All regulated tanks must have leak detection (often also called release detection) so that leaks are discovered quickly before contamination spreads from the Underground Storage Tank (UST) site.

You must provide your UST system with release detection that allows you to meet all four basic requirements:

- You can detect a leak from any portion of the tank that routinely contains petroleum.

- Your leak detection is installed and calibrated in accordance with the manufacturer’s instructions.

- Your leak detection is operated, maintained, and tested in accordance with the manufacturer’s instructions

- Your leak detection uses one of the seven methods described in the federal regulations (Section 280.43)

Additional information on the EPA UST requirements can be found at https://www.epa.gov/ust. State and local regulations may differ from the federal requirements. Contact your local agency to ensure that you are meeting all requirements.

THE 7 METHODS FOR RELEASE DETECTION

If solely relied upon by a gas station owner or operator, any one method of release detection has the potential to miss an event or its magnitude. It is best practice for gas station and convenience store operators to build a system with multiple release detection methods incorporated and manage it through the Automatic Tank Gauge.

State and local regulations may differ from the federal requirements. Contact your local agency to ensure that you are meeting all requirements.

1. Automatic Tank Gauging

2. Monitoring for Vapor in the Soil

3. Monitoring for Contamination in Groundwater

4. Interstitial Monitoring

(For tanks installed after April 11, 2016, Interstitial Monitoring is the only permissible release detection method.)

5. Statistical Inventory Reconciliation [SIR]

6. Weekly Manual Tank Gauging

(Only valid for tanks less than 2000 gallons)

7. Annual Tank Tightness Testing and either Daily Inventory Control or Manual Tank Gauging

(Only valid for tanks less than 10 years old)

Required Equipment

- An ATG that meets regulatory requirements (TLS-450PLUS)

- Probes with leak detection capability for each tank

- Optional leak testing software for Continuous Statistical Leak Detection (CSLD)

What are the regulatory requirements?

- The ATG must be able to detect a leak of 0.2 gallons per hour with a 95% probability of detection and with a false alarm rate of 5%

- The ATG must perform Inventory Control

- The ATG must be operated in one of the following modes:

- Static Leak Detection (SLD) Testing - Veeder-Root 0.2 SLD test conducted every 30 days

- Continuous Statistical Leak Detection (CSLD) - Veeder-Root CSLD mode operating on an uninterrupted basis

Required Equipment

- Vapor Sensors for monitoring wells

- An automatic tank gauge for monitoring the Vapor Sensor (TLS-450PLUS)

What are the regulatory requirements?

- There must be porous materials in the excavation zone

- The area must be free from interference such as groundwater and rainfall that would prevent detection

- There must be a sufficient number of monitoring wells

Considerations

Vapor monitoring is not recommended as sole method for compliance for a gas station because of the delay in detection and potential for wet sensors. By the time the vapor sensors go to alarm, the contamination has likely already occurred.

Required Equipment

- Groundwater Sensors

- An automatic tank gauge for monitoring the Groundwater Sensors (TLS-450PLUS)

What are the regulatory requirements?

- The groundwater level is within 20’ of ground surface

- The system is able to detect 1/8” of product on top of groundwater

- There are a sufficient number of monitoring wells

Considerations

Groundwater monitoring is not recommended as the sole method for compliance for gas station and convenience store operators because of the delay in detection. By the time the sensors go to alarm, the underground storage tank has already leaked and contamination has occurred.

INTERSTITIAL MONITORING

Interstitial monitoring requires secondary containment, like a double wall tank or double wall piping, which provides a barrier between the tank or piping system and the environment. The barrier holds the leak between the tank and the barrier so that the leak is detected.

Required Equipment

- Double walled underground storage tank (UST), in which an outer wall completely surrounds the primary tank

- Brine-filled for wet monitoring

- Dry Space (annulus) for dry monitoring

- Impermeable excavation liners that partially or completely surround the UST

- Internally fitted liners (bladders)

- An automatic tank gauge for monitoring the Interstitial Sensors (TLS-450PLUS)

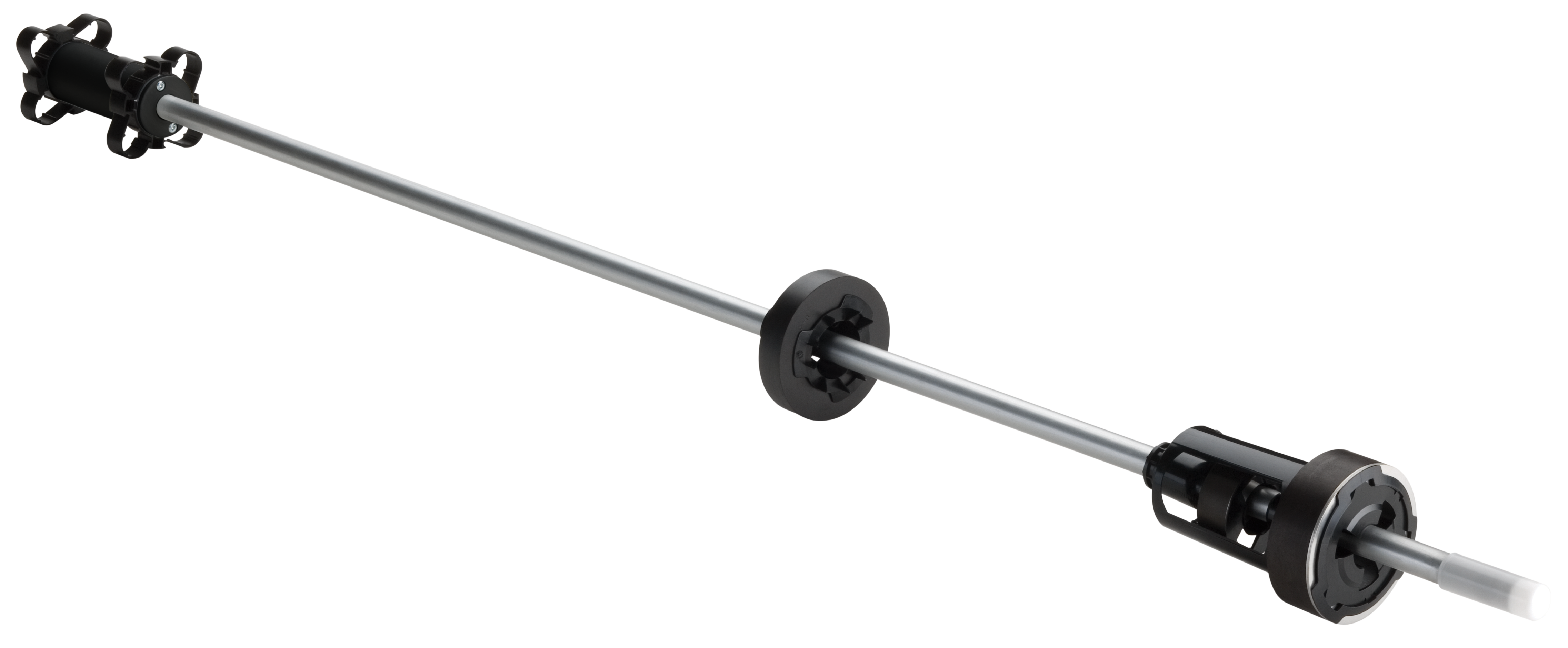

- Interstitial Sensor, could be any of the following depending on conditions:

What are the regulatory requirements?

For underground storage tanks installed after April 11, 2016, Interstitial Monitoring is the only permissible leak detection method. The interstitial monitor must be checked at least once every 30 days.

Considerations

The interstitial sensor needed will depend on the type of secondary containment barrier and the tank material being used.

STATISTICAL INVENTORY RECONCILIATION

Statistical Inventory Reconciliation (SIR) analyzes inventory, delivery, and dispensing data collected over a period of time (30 to 60 days) to determine whether or not a fuel tank system is leaking

What are the regulatory requirements?

- 0.2 gallons per hour leak detection meets monthly requirements for the life of the tank

- 0.1 gallons per hour leak detection capability meets the federal requirements as an equivalent to tank tightness testing

- If the SIR system has the ability, it can also provide a tightness test result on the product piping system

Considerations

- SIR is a vendor-supplied service that requires recurring fees

- Does not reduce the burden of collecting and transferring or transposing inventory data

What are the regulatory requirements?

- Manual tank gauging, or sticking, can only be used on tanks 2,000 gallons or smaller

- Tanks 1,000 gallons or less can use this method alone

- Tanks from 1,001 to 2,000 gallons:

- Must be combined with periodic tank tightness testing

- Only for 10 years after installing a new UST or upgrading an UST with corrosion protection

Considerations

- This method requires taking the tank out of service for at least 36 hours each week to take measurements of the tank’s contents

- Applies to a limited number of applications because of 2,000 gallon tank maximum

TANK TIGHTNESS TESTING + INVENTORY CONTROL

This is a combination of two practices: Tank tightness testing and inventory control.

Tank tightness testing requirements

- Annual test conducted by vendor who installs special equipment to test the portion of the tank that routinely contains product.

Inventory control requirements

- Daily inventory level measurements to 1/8” accuracy

- Monthly water level measurements to 1/8” accuracy

- Monthly reconciliation of deliveries and dispensing

- Monthly calculation to prove that the system is not leaking

What are the regulatory requirements?

- Must supply monthly inventory calculation, capable of detecting a leak of 1% of monthly throughput + 130 gallons, proving no leak.

- Pass an annual tank tightness test capable of detecting a leak of 0.1 gallons per hour

Considerations

- This method can only be used for 10 years after installing a new underground storage tank or upgrading an underground storage tank with corrosion protection

- Operations must be suspended during tank tightness testing

- Inventory control requirements can be met with automatic tank gauge data

USING AN AUTOMATIC TANK GAUGE TO DEMONSTRATE COMPLIANCE

Any one method of leak detection has the potential to miss an event, or its magnitude, if solely relied upon. It is best practice to build a system with multiple leak detection methods incorporated and manage it through the Automatic Tank Gauge.

| METHOD | ATG REPORT |

| Static Leak Detection | Tank Leak Test History (Passed Test Results) |

| Continuous Statistical Leak Detection | Tank Leak Test History (Passed Test Results) |

| Vapor Monitoring | Sensor Status Report |

| Groundwater Monitoring | Sensor Status Report |

| Interstitial Monitoring | Sensor Status Report |

| Tank Tightness and Inventory Control | Inventory History Report (An Annual Tank Tightness Testing Report will be required from testing contractor) |

Reports must be printed or archived every 30 days