Proud to be Powered by Vontier. Sharing a united vision that is driven by innovation. Find out more

The Cost of Doing Nothing

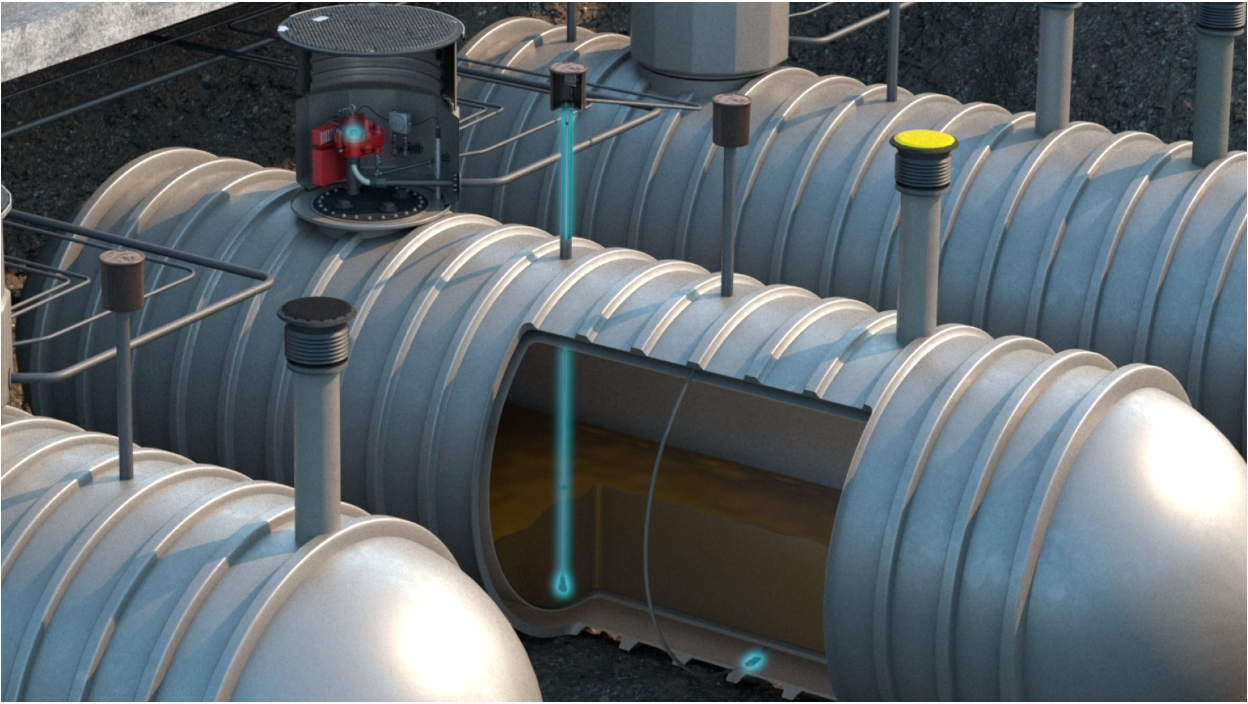

Combat CorrosionCorrosion within a diesel underground storage tank is a long-term problem for a gas station.

Read More

A Corrosive Impact on Fuel Quality

Combat CorrosionCorrosion within a fueling system can affect the quality of the fuel and impact the integrity of their equipment.

Read More

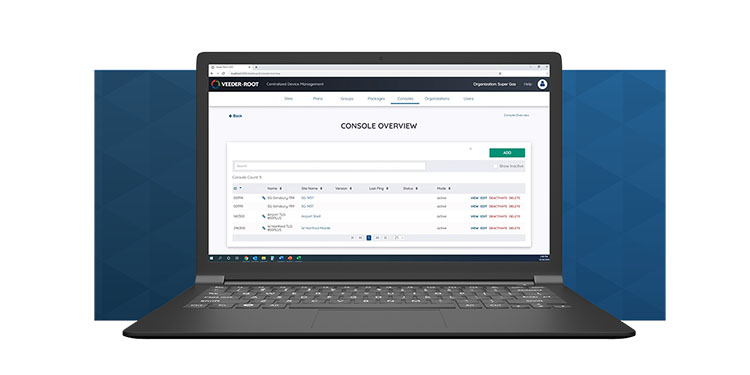

Keeping track of all that fuel

Gas Station 101It’s important that the manager on the site can maintain an understanding of the current inventory

Read More

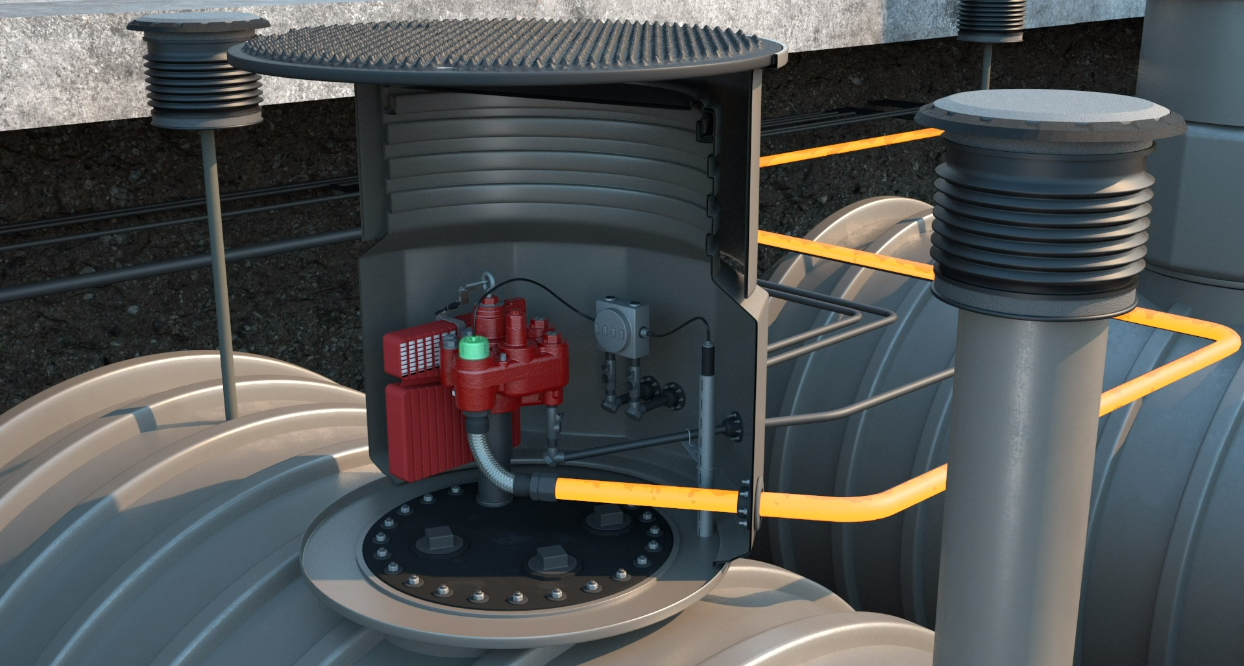

How Do Gas Stations Ensure Fuel Isn't Leaking?

Gas Station 101There are a number of ways the gas station can meet the requirements.

Read More

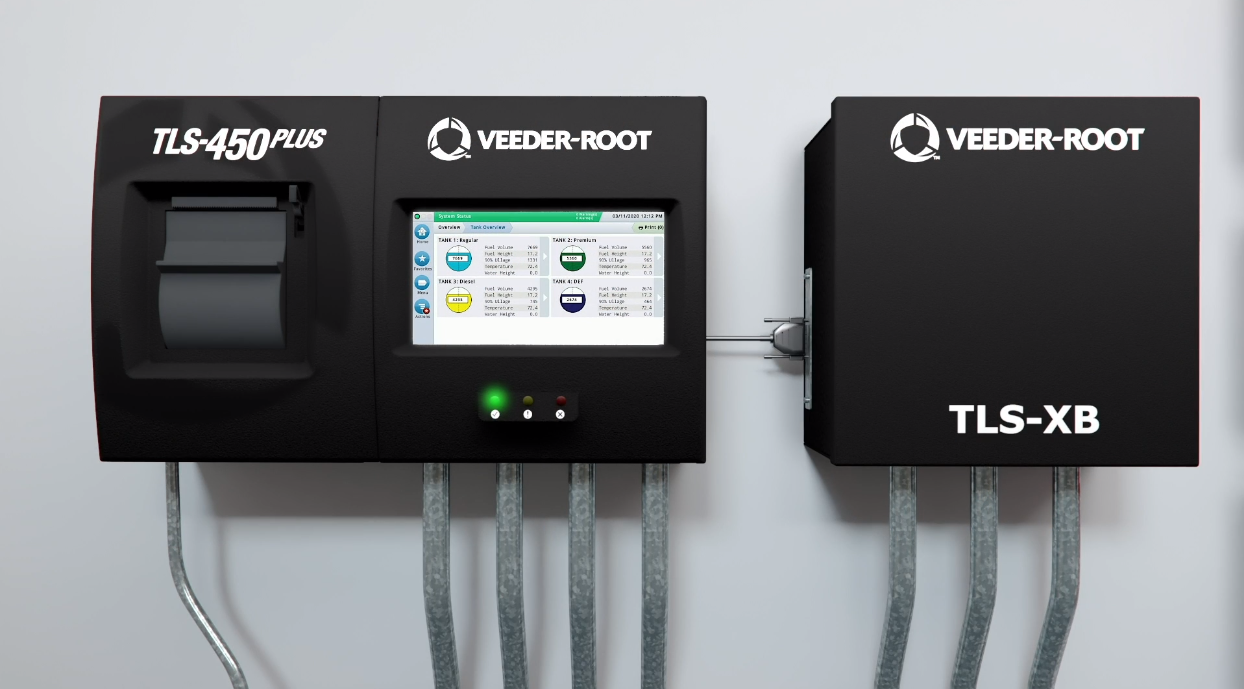

How Does the Fuel Actually Get to the Nozzle?

Gas Station 101Fuel is pumped up from an underground storage tank via a submersible turbine pump and through the fuel lines to your dispenser nozzle.

Read More

Gaining Approval and Getting Started

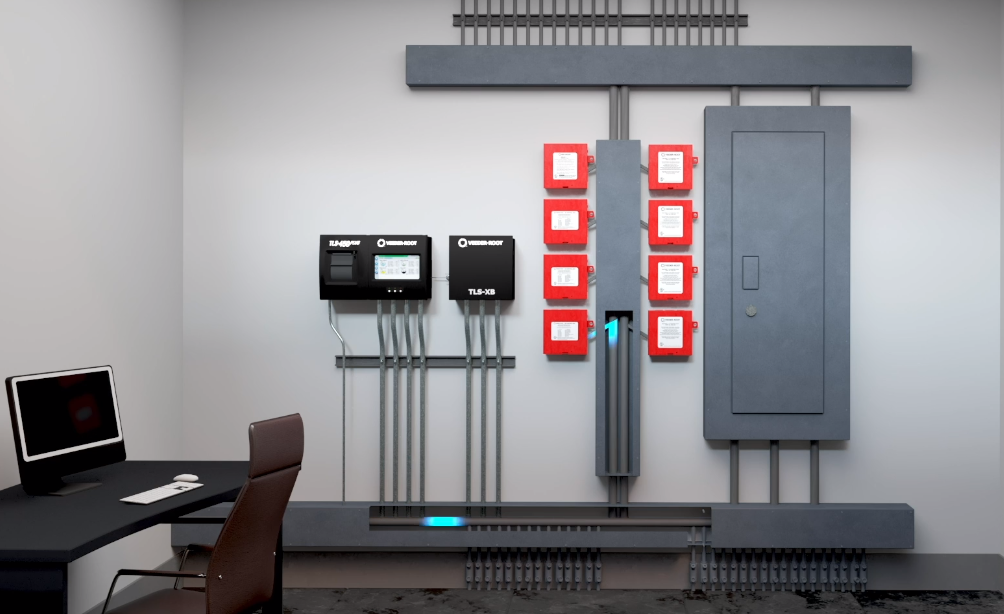

Gas Station 101There are three pieces of equipment that make up the system that manages the transactions, inventory data, and facilitate the pumping of the fuel.

Read More