Position Sensitive Interstitial Sensor

The Position Sensitive Interstitial Sensor detects the presence of liquid in small containment areas of double wall steel tanks. In addition, it provides an alarm when the sensor is not positioned correctly on the bottom of the interstitial space.

Meet regulations for position sensing and liquid detection

The Veeder-Root Position Sensitive Interstitial Sensor for Steel Tanks is designed specifically to meet regulations requiring position sensing and liquid detection technology.

The Position Sensitive Interstitial Sensor triggers an alarm when sensor is improperly positioned or when liquid activates the float.

Product Form

Part Number | Description | Notes

|

794380-333 | Position Sensitive Interstitial Sensor for Steel Tanks | |

312020-928 | 2” (50mm) Interstitial sensor riser cap kit (sold separately |

Key Features

- Compatible with existing Veeder-Root TLS monitoring systems with interstitial monitoring capability

- Detects the presence of liquid in the interstice of the double-wall tank

- Activates visual and audible alarms on the TLS monitoring system

- User-defined labeling for installation location identification

- Alarm history retrieval via printer, serial commands or graphical user interface

- Improves annual inspection time

- UL and cUL listed

- National Work Group listed

- Meets North Carolina UST Steel Tank regulation 15A NCAC 02N.0901

Specifications

Fuel Compatibility | Gas, Diesel, Kerosene, Jet Fuel, Aviation Gas, E15, E85, E100, Bio-Diesel 20, Bio-Diesel 100, Green Diesel, Waste Oil, Motor Oil |

Alarm Notification | Normal: Sensor in Normal State – No liquid detected |

Fuel Alarm: Not sitting correctly on bottom of interstitial space or liquid detected | |

Sensor Out: Sensor not communicating to ATG Console | |

Operating Principle | Reed Switch /Float |

Product Activation Height | 1.4” (3.6cm) |

Operating Temp | -4 to +140°F (-20 to +60°C) |

Dimensions | 3.5" (8.9cm) High, 1.75" (4.4cm) Diameter |

Standard Cable | 20ft (6.09m) |

Documents

- Position Sensitive Interstitial Sensor for Steel Tanks Specifications (577013-750-15)

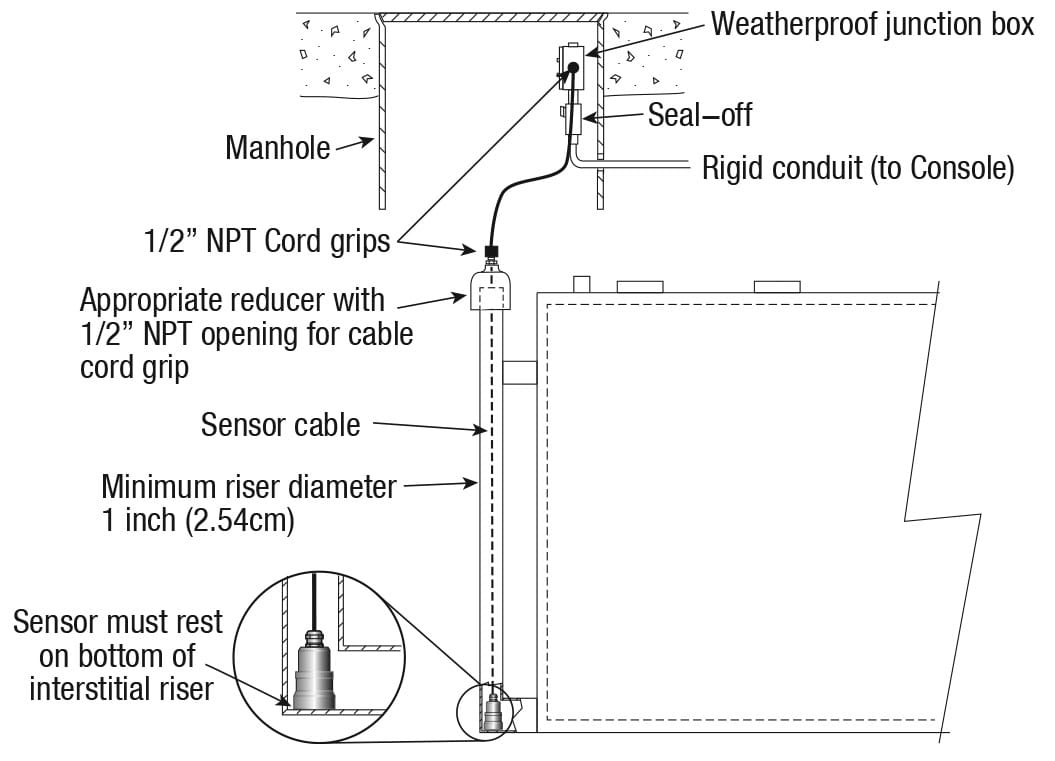

- Position Sensitive Interstitial Sensor (PSIS)–Steel Tank Installation Guide (577014-041)

- Position Sensitive Interstitial Sensor (PSIS) for Steel Tanks Brochure (576047-208)

- Sensor Products Application Guide (577013-750)

- Probe Riser Cap Kit Specifications (577014-457)