Red Jacket® LPG Premier STP

The Red Jacket® Liquefied Petroleum Gas (LPG) Premier range of submersible turbine pumps meet a wide variety of site configurations and demands for high flow performance, durability and adaptability, while maximizing profitability. Compatible with butane, propane, or any blend of the two, these multistage centrifugal pumps supply exceptional performance at peak efficiency. The LPG Premier STPs are the industry’s most efficient, cost-effective explosion-proof submersible pump/motor units, designed to pump LPG.

The Premier and Premier MidFlow are designed for standard LPG refueling applications with low to intermediate flow requirements, while the Premier HiFlow is intended for high capacity installations such as commercial vehicle fueling facilities and LP cylinder filling plants.

Basic Principle of the Red Jacket Submersible LPG Pump

LPG is a mixture of gasses, primarily propane and butane and remains a vapor until pressurized to the point of liquefication. The LPG Premier Series operates under sufficient pressure to retain the liquid state at optimal delivery rates.

This multi-stage technology provides maximum performance with efficient energy consumption:

-

2.25 kW (3 hp) for the Premier pump

-

2.25 kW (3 hp) for the MidFlow pump

-

3.75 kW (5 hp) for the HiFlow pump

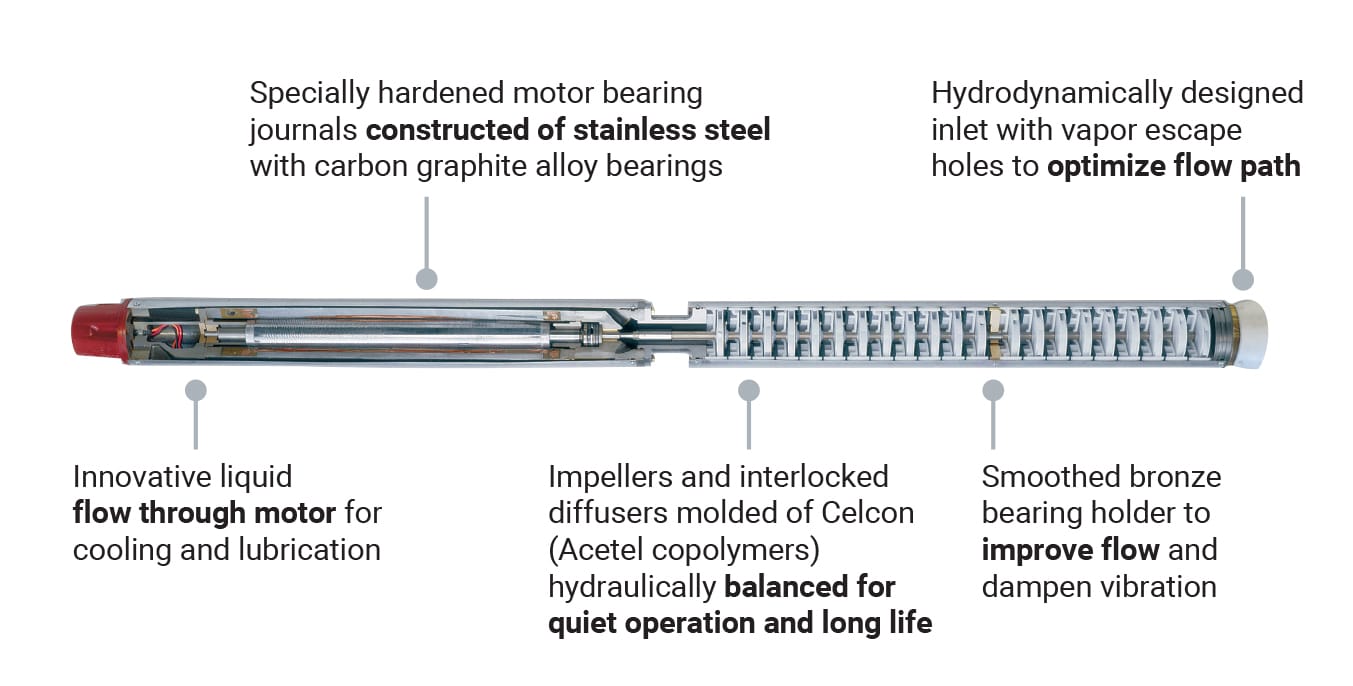

A floating impeller design eliminates unnecessary resistance and maximizes flow. All diffusers are interlocked and are enclosed in a stainless steel shell.

Staging consists of three ruggedized components:

-

The diffuser

-

The diffuser plate

-

The impeller

The Premier series controls motor temperature using an innovative internal bleed (by-pass) in the motor. Motors meet all flameproof requirements per DEMKO 13 ATEX 9483031U and IECEx UL 13.0034U certificates.

The minimum differential pressure requirement for the Red Jacket® Premier Series LPG pumps is 400 kPa (58PSI).

The Red Jacket Premier Series LPG pumps requires at least 127 mm (5.0 inches) of submersion (or Net Positive Section Head).

The Flexible Solutions to Customer Needs

The flexibility of the Red Jacket® LPG Premier Series simplifies site specifications and reduces your total cost of ownership. The Premier series is designed with a sleek and safe profile, supporting flexible applications and sufficient protection to comply with local safety regulations. With the Premier Series, Red Jacket is proud to introduce the only LPG solution capable of supplying multiple dispensers with exceptional flow rates simultaneously. As global demand for LPG continues to increase, the Red Jacket LPG Premier Series is your solution to simplify your site and maximize customer benefits:

-

Less Hardware – lower maintenance and less energy consumption

-

Consolidate Product Lines – lower installation costs

Benefits of Pressure Technology over Suction Systems

Reduced operating noise and vapor lock elimination are just the beginning. In comparison to suctions systems, pressure technology offers several benefits to revolutionize the LPG user’s experience. Compatible with all sizes of remote UST and AST installations, pressure systems provide the greatest flexibility when it comes to site construction. With fewer components, efficient power consumption and minimal maintenance, pressure systems provide a highly cost-effective solution.

Increased Flow Rates and Operator Fueling Up-time with Changing LPG Mixtures

-

Red Jacket’s Pressurized LPG Pumping technology delivers increased flow rates over suction LPG systems.

-

Pressurized LPG pumping systems eliminate differential pressure issues that can interrupt fueling operations when operators fuel their vehicles with varying mixtures of Butane vs. Propane.

Lower Installation and Maintenance Costs

-

No External By-Pass and associated solenoid and ball valve hardware needed for Pressure vs. Suction LPG systems.

-

No need to take site down for servicing of mechanical seal valves and External By-Pass hardware.

Lower Operating Costs

-

3HP LPG Pressure systems deliver comparable flow rates to a 7HP suction system.

The Best LPG Pumping Solution For Complete Peace Of Mind

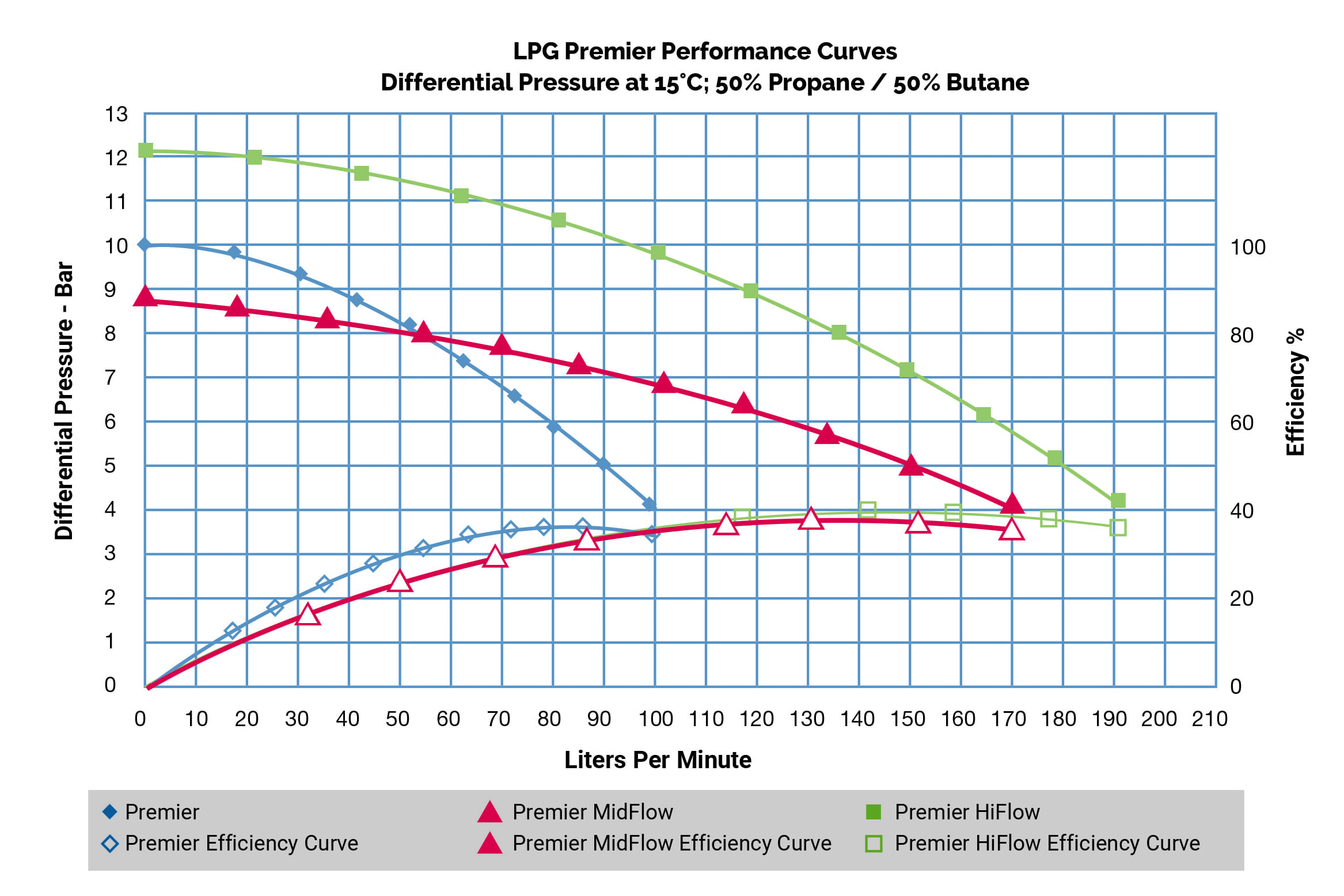

The performance curves represent the wide range of throughput requirements supported by the Premier Series:

The Premier LPG STP

- Throughput: 0-100 lpm

- Application: 1-2 Fueling Points @ 35 lpm

- Differential Pressure: 4-10 Bar

The Premier MidFlow LPG STP

- Throughput: 0-170 lpm

- Application: 2-4 Fueling Points @ 35 lpm

- Differential Pressure: 4-8.8 Bar

The Premier HighFlow LPG STP

- Throughput: 25-190 lpm

- Application: 4-5 Fueling Points @ 35 lpm or 1 Fueling Point @ 150 lpm

- Differential Pressure: 4-12.1 Bar

Product Form

|

Part Number |

Description |

Notes |

|

410115-001 |

LPG Premier |

Model Number: LPG300V17-21 |

|

410115-003 |

LPG Premier MidFlow |

Model Number: LPG300V17-17 |

|

410115-002 |

LPG Premier HiFlow |

Model Number: LPG500V17-24 |

Key Features

Quality

High Performance Leads to Customer Satisfaction

-

Avoid vapor lock under all conditions

-

Minimize operation noise

Greater Reliability

-

Fewer components

-

Longer life

-

Less maintenance

Delivery

Greatest flexibility to meet customer or regulatory requirements

-

Supports above or below ground installations

-

Compatible with most tank sizes

-

Remote or on-site installations

Safe and Easy Installation

-

No additional bypass components

-

Discrete Installation

Cost

Reduced operating costs

-

Less power consumption at optimal flow performance

-

Less maintenance

-

Compatible with larger tanks enables reduced delivery frequency

Design

Unique Design, Certified Construction

-

Certified EEx ed IIB T3 design explosion-proof submersible electric motor.

-

Bearing cooling and lubrication system for maximum cooling during dispensing, leading to longer life and lower maintenance.

-

Internal bypass for continual cooling of system prior to dispensing.

-

Multi-stage centrifugal pumping system for reduced power consumption.

-

Split pump/motor design for easy installation and maintenance.

-

High differential pressure capability for guaranteed flow performance with various LPG mixtures.

-

Robust heavy-duty construction for high durability.

-

Pressure-based system provides increased flow rates and operator fueling up-time, lower installation and maintenance costs, and lower operating costs

-

Quiet operation.

-

ATEX approved, LCIE France certified.

Documents

- LPG (Liquid Petroleum Gas) Submersible Pump Brochure - Premier and Premier HiFlow (PDF)

- LPG (Liquid Petroleum Gas) Submersible Pump Brochure - Premier MidFlow (PDF)

- LPG (Liquid Petroleum Gas) Submersible Pump Installation Manual - English (051-327-1) (PDF)

- Red Jacket Product Guide (576047-310) (PDF)