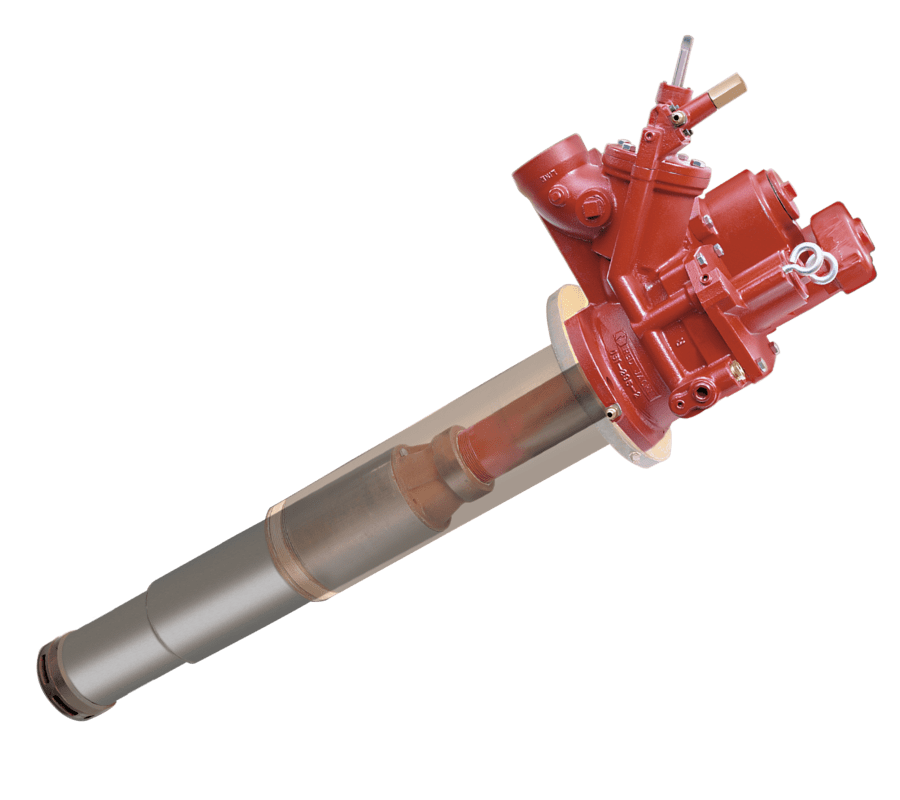

Red Jacket® Maxxum® STP

The Red Jacket® Maxxum Submersible Turbine Pump (STP) is intended for 6” high flow applications and provides the industry’s highest flow rates. The Maxxum series boasts leading serviceability and safety features. With a 3 or 5 HP motor, it’s specifically engineered for high throughput applications such as truck stops, where extreme demand, multiple fuel points, and long piping runs reduce fuel flow to the nozzle.

Product Description

The Maxxum (formerly Big Flo) STPs and unitized motor pumps (UMP) provide the industry’s highest flow rates by reducing the number of restrictions within the flow path. The efficient design also leads to less power consumption, contributing to a lower lifetime cost of operation. Easy access to valves and ports allows for reliable diagnostics and fast service.

- Reduced Wear – enhanced design results in quieter operation and less wear

- Improved Insulation Rating – higher insulation temperature rating assures longer running life

- Increased Protection – additional stainless components result in better protection for use with blended fuels

- Backwards Compatible – Maxxum UMPs are compatible with previous 3 & 5 HP Maxxum STPs

- Explosion Proof – improved design provides increased levels of safety; certified UL/cUL/IECEx/ATEX Explosion proof motor.

- Continuous Safety Improvements – design enhancements guided by newer international flame proofing standards.

Product Form

60 Hz STP Models

Part Number | Model Number | HP | KW | Voltage | Phase |

410763-006 | MXP300J4-2HB w/Siphon | 3 | 2.24 | 230 | Three |

410763-001 | MXP300J4-2HB | 3 | 2.24 | 230 | Three |

410763-008 | MXP500J4-2K w/Siphon | 5 | 3.73 | 230 | Three |

410763-003 | MXP500J4-2K | 5 | 3.73 | 230 | Three |

410763-009 | MXP500J6-2K w/Siphon | 5 | 3.73 | 575 | Three |

410763-004 | MXP500J6-2K | 5 | 3.73 | 575 | Three |

Key Features

- Delivers over 20% more flow than alternative high capacity pumps. Flow performance exceeds all other 6” Submersible Turbine Pump.

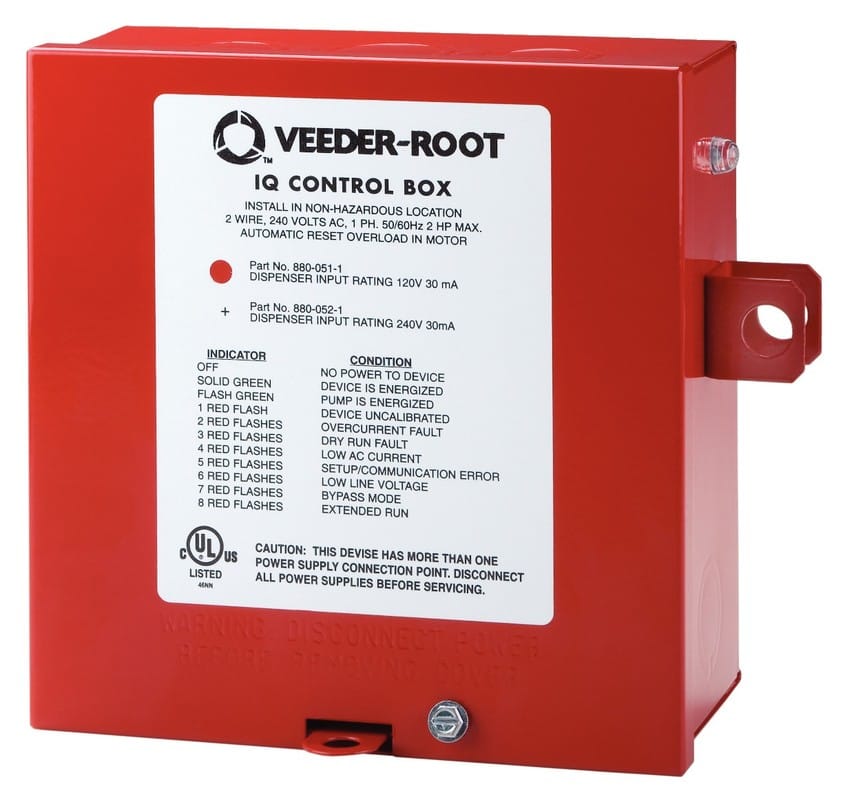

- Designed to meet Environmental Compliance requirements. Compatible with Veeder-Root Pressurized Line Lead Detector (PLLD), vapor recovery pump driving port and transducer post for electronic leak detection (ELLD).

- Easy and safe electrical yoke disconnect, termination of pump wiring in conduit box.

- Quick removal of extractable pump head and quick accessibility of check valve.

- Available with or without siphon.

- Also available in 50 Hz STP Models. Contact customer service for more information.

Specifications

Fuel Compatibility |

|

Motor Sizing |

|

Hardware Construction |

|

Operation Environment |

|

Installation Depth Range | Up to 20' |

Packer Manifold Access Ports | Siphon Ports:

Line Test Ports:

Pressure Port:

Clean out Ports

|

Check Valve |

|

Agency | UL Listings:

Other Agency Listings:

|

Documentation

- Maxxum Big Flo Data Sheet (576047-221)

- Maxxum Big Flo Spec Sheet (576047-237)

- Maxxum® Big-Flo® 6” Submersible Pump Installation, Operation & Service (577014-089)

- 6" Maxxum - 5-wire Male Connector Installation Instructions (042-232-1)

- Lock-Down Screw Installation Instructions (042-235-1)

- The Red Jacket STP Flow Quick Reference Guide (576047-523)

- Red Jacket Product Guide (576047-310)

- Maxxum STP with PLLD CAD File